Abstract

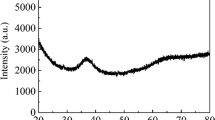

The Zr62.55Cu17.55Ni9.9Al10 bulk metallic glass (BMG) was prepared by using copper-mold suction-casting. X-ray diffraction and differential scanning calorimetry were utilized to determine its structure and thermal stability. Uniaxial compression and Rockwell indentation tests were adopted to study the plastic deformation behavior at room temperature. The results show that the glass transition temperature and the onset temperature of exothermic reaction of the BMG are 651.5 and 748 K, respectively. During the compression test, the BMGs undergo an engineering strain of about 2.5%, i.e., true strain of 2.8%, and then fracture. The BMGs deform via the formation and propagation of shear bands. Under indentation loading, the BMGs deform through the formation of radiation-like and circular shear bands. The circular shear bands form earlier than the radiation-like ones. The formation mechanism of shear bands in the BMGs was analyzed and discussed.

Similar content being viewed by others

References

Q. Jing, R.P. Liu, G.J. Shao, et al., Preparation and super-plastic deformation of the Zr-based bulk metallic glass, Mater. Sci. Eng. A, 359(2003), No.1–2, p.402.

Y. Zhang and A.L. Greer, Thickness of shear bands in metallic glasses, Appl. Phys. Lett., 89(2006), No.7, art. No.071907.

H. Men, S.J. Pang, and T. Zhang, Glass-forming ability and mechanical properties of Cu, Zr, Ti, alloys, Mater. Sci. Eng. A, 408(2005), No.1–2, p.326.

T. Wada and A. Inoue, Thermal stability and mechanical properties of porous bulk glassy Pd-Cu-Ni-P alloys, Mater. Trans., 44(2003), No.10, p.2228.

B. Yang, L. Riester, and T.G. Nieh, Strain hardening and recovery in a bulk metallic glass under nanoindentation, Scripta Mater., 54(2006), No.7, p.1277.

B.C. Wei, T.H. Zhang, W.H. Li, et al., Serrated plastic flow during nanoindentation in Nd-based bulk metallic glasses, Intemetallics, 12(2004), No.10–11, p.1239

M.H. Lee, D.H. Bae, D.H. Kim, et al., Nanocrystallization at shear bands in bulk metallic glass matrix composites, Scripta Mater., 58(2008), No.8, p.651.

P.J. Tao, Y.Z. Yang, X.J. Bai, et al., Zr-based bulk metallic glass with super-plasticity under uniaxial compression at room temperature, J. Non Cryst. Solids, 354(2008), No.31, p.3742.

L.Y. Chen, A.D. Setyawan, H. Kata, et al., Free-volume-induced enhancement of plasticity in a monolithic bulk metallic glass at room temperature, Scripta Mater., 59(2008), No.1, p.75.

P.J. Tao, Y.Z. Yang, X.J. Bai, et al., Super-plasticity of Zr64.80Cu14.85Ni10.35Al10 bulk metallic glass at room temperature, Chin. Sci. Bull., 53(2008), No.3, p.465.

G.B. Shan, J.X. Li, Y.Z. Yang, et al., Hydrogen-enhanced plastic deformation during indentation for bulk metallic glass of Zr65Al7.5Ni10Cu17.5, Mater. Lett., 61(2007), No.8–9, p.1625.

R.D. Conner, Y. Li, W.D. Nix, et al., Shear band spacing under bending of Zr-based metallic glass plates, Acta Mater., 52(2004), No.7, p.2429.

H. Bei, S. Xie, and E.P. George, Softening caused by profuse shear banding in a bulk metallic glass, Phys. Rev. Lett., 96(2006), No.10, art. No.105503.

J. Saida, A.D.H. Setyawan, H. Kato, et al., Nanoscale multistep shear band formation by deformation-induced nanocrystallization in Zr-Al-Ni-Pd bulk metallic glass, Appl. Phys. Lett., 87(2005), No.15, art. No.151907, p.1.

K.F. Yao and C.Q. Zhang, Fe-based bulk metallic glass with high plasticity, Appl. Phys. Lett., 90(2007), No.6, art. No.0619001.

X.J. Gu, A.G. Mcdermott, S.J. Poon, et al., Critical Poisson’s ratio for plasticity in Fe-Mo-C-B-Ln bulk amorphous steel, Appl. Phys. Lett., 88(2006), No.21, art. No.211905.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National Natural Science Foundation of China (Nos.50971046, 50771037, and 50371020) and the Doctoral Fund of the Ministry of Education of China (No.200805620004).

Rights and permissions

About this article

Cite this article

Tao, Pj., Yang, Yz., Bai, Xj. et al. Room temperature plastic deformation behavior of ZrCuNiAl bulk metallic glasses. Int J Miner Metall Mater 17, 327–330 (2010). https://doi.org/10.1007/s12613-010-0313-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-010-0313-9