Abstract

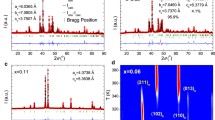

The development of zero and negative thermal expansion (i.e., ZTE and NTE) materials is of crucial importance to the control of undesirable thermal expansion for high-precision devices. In the present work, ZTE and NTE were obtained in directionally-solidified MnxFe5–xSi3 alloys with a strong <001> texture, in striking contrast to positive thermal expansion in their isotropic counterparts. Magnetometry and in-situ X-ray diffraction (XRD) measurements were performed to uncover the origin of the anomalous thermal expansion. Magnetic measurements indicate a strong easy-plane magnetocrystalline anisotropy in the textured samples, where the magnetic moments are aligned within the ab plane of the hexagonal structure. Temperature-dependent XRD on the x = 1 sample reveals a ZTE character in the ab plane that is coupled to a ferromagnetic transition. As a result, the macroscopic ZTE (~ 0.22 × 10–6 K−1) in the x = 1 sample can be attributed to the microscopic magneto volume effect within the ab plane, which is realized by the introduction of the <001>-textured microstructure. Besides, the competition between antiferromagnetic and ferromagnetic exchange coupling leads to NTE in textured x = 1.5 and 2 samples. Additionally, textured x = 1 sample displays enhanced magnetocaloric properties as compared to the conventional counterparts with randomly-oriented grains. Consequently, this work demonstrates a new strategy toward the exploration of anomalous thermal expansion properties as well as the enhancement of magnetocaloric properties for materials with a strong magnetocrystalline anisotropy.

Graphical abstract

摘要

零热膨胀和负热膨胀 (即ZTE和NTE) 材料对于控制精密元器件的尺寸稳定性至关重要。本研究通过定向凝固技术制备了具有 < 001 > 织构的MnxFe5–xSi3 合金, 获得了常规各向同性样品不具有的ZTE和NTE性能。进一步利用磁测量和原位X 射线衍射(XRD) 研究了其反常热膨胀的物理起源。磁测量表明, MnxFe5–xSi3系列样品具有较强的磁晶各向异性, 磁矩沿着六方结构的 ab 面排列。变温 XRD结果表明, x = 1 样品的六方晶胞在ab 面内呈现出ZTE, 并且该ZTE行为与铁磁相变同时发生。因此, x = 1 样品的宏观 ZTE (~ 0.22 × 10–6 K−1)来源于ab 面内的微观磁体积效应与晶粒择优取向的协同作用。x = 1.5和2样品中反铁磁与铁磁交换作用之间的相互竞争进一步增强了磁体积效应, 使得其呈现出NTE。 此外, 与常规各向同性样品相比, 晶粒择优取向样品表现出更强的磁热效应。 因此, 本研究提供了一种开发反常热膨胀材料的新思路以及增强磁热效应的新策略。

Similar content being viewed by others

References

Mary TA, Evans JSO, Vogt T, Sleight AW. Negative thermal expansion from 0.3 to 1050 kelvin in ZrW2O8. Science. 1996;272:90. https://doi.org/10.1126/science.272.5258.90.

Xu J, Wang Z, Huang H, Li Z, Chi X, Wang D, Zhang J, Zheng X, Shen J, Zhou W, Gao Y, Cai J, Zhao T, Wang S, Zhang Y, Shen B. Significant zero thermal expansion via enhanced magnetoelastic coupling in kagome magnets. Adv Mater. 2023;35:e2208635. https://doi.org/10.1002/adma.202208635.

Rao Z, Tung P-Y, Xie R, Wei Y, Zhang H, Ferrari A, Klaver TPC, Körmann F, Sukumar PT, Kwiatkowski da Silva A, Chen Y, Li Z, Ponge D, Neugebauer J, Gutfleisch O, Bauer S, Raabe D. Machine learning-enabled high-entropy alloy discovery. Science. 2022;378:78. https://doi.org/10.1126/science.abo4940.

Li W, Lin K, Yan Y, Yu C, Cao Y, Chen X, Wang CW, Kato K, Chen Y, An K, Zhang Q, Gu L, Li Q, Deng J, Xing X. A seawater-corrosion-resistant and isotropic zero thermal expansion (Zr, Ta)(Fe, Co)2 alloy. Adv Mater. 2022;34:e2109592. https://doi.org/10.1002/adma.202109592.

Hao Y, Zhou Y, Zhao M. Thermal expansion anomaly and spontaneous magnetostriction of Tb2Fe15Cr2 compound. Rare Met. 2006;25(2):156. https://doi.org/10.1016/s1001-0521(06)60032-6.

Yu C, Lin K, Jiang S, Cao Y, Li W, Wang Y, Chen Y, An K, You L, Kato K, Li Q, Chen J, Deng J, Xing X. Plastic and low-cost axial zero thermal expansion alloy by a natural dual-phase composite. Nat Commun. 2021;12:4701. https://doi.org/10.1038/s41467-021-25036-1.

Song Y, Shi N, Deng S, Xing X, Chen J. Negative thermal expansion in magnetic materials. Prog Mater Sci. 2021;121:100835. https://doi.org/10.1016/j.pmatsci.2021.100835.

Chen J, Hu L, Deng J, Xing X. Negative thermal expansion in functional materials: controllable thermal expansion by chemical modifications. Chem Soc Rev. 2015;44:3522. https://doi.org/10.1039/c4cs00461b.

Hao YM, Zhou Y, Zhao M. Spontaneous volume magnetostriction of DY2AlFe12Mn4 compound. Rare Met. 2006;25(1):43. https://doi.org/10.1016/s1001-0521(06)60012-0.

Zhang Y, Chen B, Guan D, Xu M, Ran R, Ni M, Zhou W, O’Hayre R, Shao Z. Thermal-expansion offset for high-performance fuel cell cathodes. Nature. 2021;591:246. https://doi.org/10.1038/s41586-021-03264-1.

Zou H, Yang X, Chen B, Du Y, Ren B, Sun X, Qiao X, Zhang Q, Wang F. Thermal enhancement of upconversion by negative lattice expansion in orthorhombic Yb2W3O12. Angew Chem Int Ed. 2019;58:17255. https://doi.org/10.1002/anie.201910277.

Toropova MM, Steeves CA. Adaptive bimaterial lattices to mitigate thermal expansion mismatch stresses in satellite structures. Acta Astronaut. 2015;113:132. https://doi.org/10.1016/j.actaastro.2015.03.022.

Wieme J, Van Speybroeck V. Unravelling thermal stress due to thermal expansion mismatch in metal–organic frameworks for methane storage. J Mater Chem A. 2021;9:4898. https://doi.org/10.1039/d0ta09462e.

Coates CS, Goodwin AL. How to quantify isotropic negative thermal expansion: magnitude, range, or both? Mater Horiz. 2019;6:211. https://doi.org/10.1039/c8mh01065j.

Guillaume CÉ. 1897 Recherches sur les aciers au nickel. Dilatations aux temperatures elevees; resistance electrique. CR Acad Sci; 125.

van Schilfgaarde M, Abrikosov IA, Johansson B. Origin of the Invar effect in iron–nickel alloys. Nature. 1999;400:46. https://doi.org/10.1038/21848.

Tan H, Wang Y, Wang G, Zhang F, Fan W, Feng Z, Lin X. Investigation on microstructure and properties of laser solid formed low expansion Invar 36 alloy. J Mater Res Technol. 2020;9:5827. https://doi.org/10.1016/j.jmrt.2020.03.108.

Aldalur E, Suárez A, Veiga F. Thermal expansion behaviour of Invar 36 alloy parts fabricated by wire-arc additive manufacturing. J Mater Res Technol. 2022;19:3634. https://doi.org/10.1016/j.jmrt.2022.06.114.

Li LF, Tong P, Zou YM, Tong W, Jiang WB, Jiang Y, Zhang XK, Lin JC, Wang M, Yang C, Zhu XB, Song WH, Sun YP. Good comprehensive performance of Laves phase Hf1-xTaxFe2 as negative thermal expansion materials. Acta Mater. 2018;161:258. https://doi.org/10.1016/j.actamat.2018.09.029.

Cao Y, Lin K, Khmelevskyi S, Avdeev M, Taddei KM, Zhang Q, Huang Q, Li Q, Kato K, Tang CC, Gibbs A, Wang CW, Deng J, Chen J, Zhang H, Xing X. Ultrawide temperature range super-Invar behavior of R2(Fe, Co)17 materials (R = rare earth). Phys Rev Lett. 2021;127:055501. https://doi.org/10.1103/PhysRevLett.127.055501.

Xu J, Zheng X, Yang S, Xi L, Wang S, Zhang L, Yang W, Yang J, Ma X, Chen D, He L, Deng S, Zhang J, Wu Y, Shen B. Large linear negative thermal expansion in NiAs-type magnetic intermetallic Cr-Te-Se compounds. Inorg Chem. 2020;59:8603. https://doi.org/10.1021/acs.inorgchem.0c01048.

Lin K, Li W, Yu C, Jiang S, Cao Y, Li Q, Chen J, Zhang M, Xia M, Chen Y, An K, Li X, Zhang Q, Gu L, Xing X. High performance and low thermal expansion in Er-Fe-V-Mo dual-phase alloys. Acta Mater. 2020;198:271. https://doi.org/10.1016/j.actamat.2020.08.012.

Yu C, Lin K, Chen X, Jiang S, Cao Y, Li W, Chen L, An K, Chen Y, Yu D, Kato K, Zhang Q, Gu L, You L, Kuang X, Wu H, Li Q, Deng J, Xing X. Superior zero thermal expansion dual-phase alloy via boron-migration mediated solid-state reaction. Nat Commun. 2023;14:3135. https://doi.org/10.1038/s41467-023-38929-0.

Li W, Huang R, Wang W, Zhao Y, Li S, Huang C, Li L. Abnormal thermal expansion properties of cubic NaZn13-type La(Fe, Al)13 compounds. Phys Chem Chem Phys. 2015;17:5556. https://doi.org/10.1039/c4cp05064a.

Chen X, Ni C, Zhao M. Magnetic phase transition and magnetocaloric effect of Tb3NiSi2 alloy. Chin J Rare Metals. 2021;45(2):169. https://doi.org/10.13373/j.cnki.cjrm.xy19060032.

Weiss P, Piccard A. Le phénomène magnétocalorique. J Phys Theor Appl. 1917;7:103. https://doi.org/10.1051/jphystap:019170070010300.

Gebara P. Magnetocaloric effect of LaFe11.35Co0.6Si1.05 alloy. Rare Met. 2022;41(5):1563. https://doi.org/10.1007/s12598-017-0917-6.

Zheng D, Jing C, Lu B, Li Z, Xu K. Martensitic transformation, magnetocaloric effect and phase transition strain in Ni50Mn36-xGexSn14 Heusler alloys. Rare Met. 2022;41(12):4217. https://doi.org/10.1007/s12598-016-0820-6.

Guan Z, Bai J, Zhang Y, Gu J, Jiang X, Liang X, Huang R, Zhang Y, Esling C, Zhao X, Zuo L. Revealing essence of magnetostructural coupling of Ni-Co-Mn-Ti alloys by first-principles calculations and experimental verification. Rare Met. 2022;41(6):1933. https://doi.org/10.1007/s12598-021-01947-2.

Huang R, Liu Y, Fan W, Tan J, Xiao F, Qian L, Li L. Giant negative thermal expansion in NaZn13-type La(Fe, Si, Co)13 compounds. J Am Chem Soc. 2013;135:11469. https://doi.org/10.1021/ja405161z.

Zhao YY, Hu FX, Bao LF, Wang J, Wu H, Huang QZ, Wu RR, Liu Y, Shen FR, Kuang H, Zhang M, Zuo WL, Zheng XQ, Sun JR, Shen BG. Giant negative thermal expansion in bonded MnCoGe-based compounds with Ni2In-type hexagonal structure. J Am Chem Soc. 2015;137:1746. https://doi.org/10.1021/ja510693a.

Shen FR, Kuang H, Hu FX, Wu H, Huang QZ, Liang FX, Qiao KM, Li J, Wang J, Liu Y, Zhang L, He M, Zhang Y, Zuo WL, Sun JR, Shen BG. Ultra-low thermal expansion realized in giant negative thermal expansion materials through self-compensation. APL Mater. 2017;5:106102. https://doi.org/10.1063/1.4990481.

Lin J, Tong P, Zhang K, Tong H, Guo X, Yang C, Wu Y, Wang M, Lin S, Chen L, Song W. Colossal negative thermal expansion with an extended temperature interval covering room temperature in fine-powdered Mn0.98CoGe. Appl Phys Lett. 2016;109:241903. https://doi.org/10.1063/1.4972234.

Shen F, Zhou H, Hu F, Wang JT, Deng S, Wang B, Wu H, Huang Q, Wang J, Chen J, He L, Hao J, Yu Z, Liang F, Liang T, Sun J, Shen B. Cone-spiral magnetic ordering dominated lattice distortion and giant negative thermal expansion in Fe-doped MnNiGe compounds. Mater Horiz. 2020;7:804. https://doi.org/10.1039/c9mh01602c.

Ren Q, Hutchison W, Wang J, Studer A, Wang G, Zhou H, Ma J, Campbell SJ. Negative thermal expansion of Ni-doped MnCoGe at room-temperature magnetic tuning. ACS Appl Mater Interfaces. 2019;11:17531. https://doi.org/10.1021/acsami.9b02772.

Zhao W, Sun Y, Liu Y, Shi K, Lu H, Song P, Wang L, Han H, Yuan X, Wang C. Negative thermal expansion over a wide temperature range in Fe-doped MnNiGe composites. Front Chem. 2018;6:15. https://doi.org/10.3389/fchem.2018.00015.

Song Y, Chen J, Liu X, Wang C, Zhang J, Liu H, Zhu H, Hu L, Lin K, Zhang S, Xing X. Zero thermal expansion in magnetic and metallic Tb(Co, Fe)2 intermetallic compounds. J Am Chem Soc. 2018;140:602. https://doi.org/10.1021/jacs.7b12235.

Songlin D, Tegus O, Brück E, Klaasse JCP, de Boer FR, Buschow KHJ. Magnetic phase transition and magnetocaloric effect in Mn5-xFexSi3. J Alloys Compd. 2002;334:249. https://doi.org/10.1016/S0925-8388(01)01776-5.

Gourdon O, Gottschlich M, Persson J, Cdl C, Petricek V, McGuire MA, Brückel T. Toward a better understanding of the magnetocaloric effect: an experimental and theoretical study of MnFe4Si3. J Solid State Chem. 2014;216:56. https://doi.org/10.1016/j.jssc.2014.05.001.

Hering P, Friese K, Voigt J, Persson J, Aliouane N, Grzechnik A, Senyshyn A, Brückel T. Structure, magnetism, and the magnetocaloric effect of MnFe4Si3 single crystals and powder samples. Chem Mater. 2015;27:7128. https://doi.org/10.1021/acs.chemmater.5b03123.

Herlitschke M, Klobes B, Sergueev I, Hering P, Perßon J, Hermann RP. Elasticity and magnetocaloric effect in MnFe4Si3. Phys Rev B. 2016;93:094304. https://doi.org/10.1103/PhysRevB.93.094304.

Maraytta N, Skourski Y, Voigt J, Friese K, Herrmann MG, Perßon J, Wosnitza J, Salman SM, Brückel T. Direct measurements of the magneto-caloric effect of MnFe4Si3 in pulsed magnetic fields. J Alloys Compd. 2019;805:1161. https://doi.org/10.1016/j.jallcom.2019.07.113.

Biniskos N, Raymond S, Schmalzl K, Schneidewind A, Voigt J, Georgii R, Hering P, Persson J, Friese K, Brückel T. Spin dynamics of the magnetocaloric compound MnFe4Si3. Phys Rev B. 2017;96:104407. https://doi.org/10.1103/PhysRevB.96.104407.

Yu C, Lin K, Cao Y, Li W, Chen Y, An K, Wang CW, Kato K, Li Q, Deng J, Xing X. Two-dimensional zero thermal expansion in low-cost MnxFe5-xSi3 alloys via integrating crystallographic texture and magneto-volume effect. Sci China Mater. 2022;65:1912. https://doi.org/10.1007/s40843-021-1996-2.

Li Q, Onuki Y, Sun Q. Tailoring thermal expansion of shape memory alloys through designed reorientation deformation. Acta Mater. 2021;218:117201. https://doi.org/10.1016/j.actamat.2021.117201.

Li Q, Deng Z, Onuki Y, Wang W, Li L, Sun Q. In-plane low thermal expansion of NiTi via controlled cross rolling. Acta Mater. 2021;204:116506. https://doi.org/10.1016/j.actamat.2020.116506.

Rodriguez-Carvajal J. Recent advances in magnetic structure determination by neutron powder diffraction. Phys B. 1993;192:55. https://doi.org/10.1016/0921-4526(93)90108-I.

Bińczycka H, Dimitrijević Ž, Gajić B, Szytula A. Atomic and magnetic structure of Mn5-xFexSi3. Phys Status Solidi A. 1973;19:K13. https://doi.org/10.1002/pssa.2210190145.

Johnson V, Weiher JF, Frederick CG, Rogers DB. Magnetic and Mössbauer effect studies of Mn5Si3:Fe5Si3 solid solutions. J Solid State Chem. 1972;4:311. https://doi.org/10.1016/0022-4596(72)90122-3.

Gercsi Z, Sandeman KG. Structurally driven metamagnetism in MnP and related Pnma compounds. Phys Rev B. 2010;81:224426. https://doi.org/10.1103/PhysRevB.81.224426.

Gercsi Z, Hono K, Sandeman KG. Designed metamagnetism in CoMnGe1-xPx. Phys Rev B. 2011;83:174403. https://doi.org/10.1103/PhysRevB.83.174403.

Eich A, Grzechnik A, Caron L, Cheng Y, Wilden J, Deng H, Hutanu V, Meven M, Hanfland M, Glazyrin K, Hering P, Herrmann MG, Ait Haddouch M, Friese K. Magnetocaloric Mn5Si3 and MnFe4Si3 at variable pressure and temperature. Mater Res Express. 2019;6:096118. https://doi.org/10.1088/2053-1591/ab33b3.

Dung NH, Ou ZQ, Caron L, Zhang L, Thanh DTC, de Wijs GA, de Groot RA, Buschow KHJ, Brück E. Mixed magnetism for refrigeration and energy conversion. Adv Energy Mater. 2011;1:1215. https://doi.org/10.1002/aenm.201100252.

Miao X, Gong Y, Caron L, You Y, Xu G, Sheptyakov D, Manuel P, Qian F, Zhang Y, Xu F, van Dijk N, Brück E. Switching the magnetostructural coupling in MnCoGe-based magnetocaloric materials. Phys Rev Mater. 2020;4:104407. https://doi.org/10.1103/PhysRevMaterials.4.104407.

Caron L, Miao XF, Klaasse JCP, Gama S, Bruck E. Tuning the giant inverse magnetocaloric effect in Mn2-xCrxSb compounds. Appl Phys Lett. 2013;103:112404. https://doi.org/10.1063/1.4821197.

Gruner ME, Keune W, Roldan Cuenya B, Weis C, Landers J, Makarov SI, Klar D, Hu MY, Alp EE, Zhao J, Krautz M, Gutfleisch O, Wende H. Element-resolved thermodynamics of magnetocaloric LaFe13-xSix. Phys Rev Lett. 2015;114:057202. https://doi.org/10.1103/PhysRevLett.114.057202.

Zhang H, Li Y, Liu E, Ke Y, Jin J, Long Y, Shen B. Giant rotating magnetocaloric effect induced by highly texturing in polycrystalline DyNiSi compound. Sci Rep. 2015;5:11929. https://doi.org/10.1038/srep11929.

Barua R, Lejeune BT, Ke L, Hadjipanayis G, Levin EM, McCallum RW, Kramer MJ, Lewis LH. Anisotropic magnetocaloric response in AlFe2B2. J Alloys Compd. 2018;745:505. https://doi.org/10.1016/j.jallcom.2018.02.205.

Zhang H, Xing C, Zhou H, Zheng X, Miao X, He L, Chen J, Lu H, Liu E, Han W, Zhang H, Wang Y, Long Y, van Eijk L, Brück E. Giant anisotropic magnetocaloric effect by coherent orientation of crystallographic texture and rare-earth ion moments in HoNiSi ploycrystal. Acta Mater. 2020;193:210. https://doi.org/10.1016/j.actamat.2020.04.031.

Zhou X, Shang Y, Luo T, Peng Y, Fu H. Large rotating magnetocaloric effect of textured polycrystalline HoB2 alloy contributed by anisotropic ferromagnetic susceptibility. Appl Phys Lett. 2022;120:132401. https://doi.org/10.1063/5.0088571.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 12004179, U1832191, 51801102, 52271180, 52001167 and 52101236), Guangdong-Hong Kong-Macao Joint Laboratory for Neutron Scattering Science and Technology, the Fundamental Research Funds for the Central Universities (No. 30922010802) and the Sino-German Mobility Program from the Sino-German Center for Research Promotion (SGC) (No. M-0447). This work was carried out in the framework of the Joint Lab BiBer.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gong, Y., Miao, XF., Samanta, T. et al. Anomalous thermal expansion and enhanced magnetocaloric effect in <001>-textured MnxFe5–xSi3 alloys. Rare Met. 43, 2263–2274 (2024). https://doi.org/10.1007/s12598-023-02575-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02575-8