Abstract

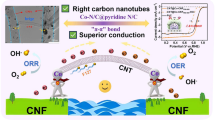

The low yield of MXene is normally related to the delaminating step, contributing to the key technical challenges in moving toward industrial applications. Here, a shearing-force-driven strategy is proposed for re-exfoliating waste MXene residue to prepare oxidatively stable MXene composites in a low-cost manner, where the strong shear stress in the assisted solvent, such as carbon nanotubes (CNTs), chitosan (CS), and polyacrylamide (PAM) aqueous solutions, acts on the surface of MXene (Ti3C2Tx) through coordination between hydroxyl and Ti atoms, resulting in a rapid and efficient exfoliation of waste Ti3C2Tx residue under stirring. Furthermore, this formed coordinate bond helps to stabilize the low-valent Ti atoms on the surface of MXene, thereby enhancing the oxidative stability of Ti3C2Tx. Besides, the CNT@MXene composite is selected to construct a free-standing membrane to encapsulate Si nanoparticles, achieving a high and reversible capacity after 50 cycles. This work supports the concept of valorizing waste and adopts a fluid shear force-assisted method to re-exfoliate waste residues, which greatly reduces the cost of processing and improves the chemical stability of MXene. More importantly, this work has uncovered a new direction for the commercialization of MXene composites and has significantly improved the real-world applications of MXene-based materials.

Graphical abstract

摘要

剥离是决定MXene 产率的关键性步骤之一,同时也是抑制MXene 商业化应用的关键技术。 基于此,我们提出采用剪切应力辅助策略对废弃MXene 残渣进行再剥离,制备高稳定 MXene 复合材料。碳纳米管水溶液,壳聚糖水溶液,聚丙烯酰胺水溶液均具有较强的剪切 应力,在搅拌过程中,这些溶剂中含有的大量羟基与MXene 表面的Ti 原子发生配位作用, 使得MXene 块体实现高效快速的剥离。更重要的是,这种形成的配位键有助于稳定 MXene 表面的低价 Ti 原子,从而显著提高 Ti3C2Tx 的抗氧化能力。此外,采用CNT@MXene 复 合材料来封装硅纳米颗粒,进而构建自支撑的硅负极,在循环50 周之后,获得较高的可逆 脱嵌容量。该项工作践行了“变废为宝”的理念,采用流体剪切力辅助的策略对MXene 废渣 进行再剥离,大大降低了加工成本,提高了 MXene 的化学稳定性。更重要的是,这项工作 为 MXene 复合材料的商业化开辟了新的方向,有助于进一步提升MXene 基材料的实际 应用。

Similar content being viewed by others

References

Naguib M, Kurtoglu M, Presser V, Lu J, Niu J, Heon M, Hultman L, Gogotsi Y, Barsoum MW. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv Mater. 2011;23(37):4248. https://doi.org/10.1002/adma.201102306.

Anasori B, Lukatskaya MR, Gogotsi Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat Rev Mater. 2017;2(2):16098. https://doi.org/10.1038/natrevmats.2016.98.

Ming F, Liang H, Huang G, Bayhan Z, Alshareef HN. MXenes for rechargeable batteries beyond the lithium-ion. Adv Mater. 2021;33(1):2004039. https://doi.org/10.1002/adma.202004039.

Liu J, Li J, Wang Y, Dong D, Yin Y, Jin H, Sun S, Dou H, Shi Y, Fu L. Technology development analysis on low carbon for power of heavy-duty commercial vehicle. Autom Innov. 2019;2(1):64. https://doi.org/10.1007/s42154-019-00054-4.

Lukatskaya MR, Mashtalir O, Ren CE, Dall’Agnese Y, Rozier P, Taberna PL, Naguib M, Simon P, Barsoum MW, Gogotsi Y. Cation intercalation and high volumetric capacitance of two-dimensional titanium carbide. Science. 2013;341(6153):1502. https://doi.org/10.1126/science.1241488.

Huang Y, Lu Q, Wu D, Jiang Y, Liu Z, Chen B, Zhu M, Schmidt OG. Flexible MXene films for batteries and beyond. Carbon Energy. 2022. https://doi.org/10.1002/cey2.200.

Liu P, Liu W, Liu K. Rational modulation of emerging MXene materials for zinc-ion storage. Carbon Energy. 2022;4(1):60. https://doi.org/10.1002/cey2.154.

Zhu C, Geng F. Macroscopic MXene ribbon with oriented sheet stacking for high-performance flexible supercapacitors. Carbon Energy. 2021;3(1):142. https://doi.org/10.1002/cey2.65.

Tang J, Peng X, Lin T, Huang X, Luo B, Wang L. Confining ultrafine tin monophosphide in Ti3C2Tx interlayers for rapid and stable sodium ion storage. eScience. 2021;1(2):203. https://doi.org/10.1016/j.esci.2021.12.004.

Liang G, Li X, Wang Y, Yang S, Huang Z, Yang Q, Wang D, Dong B, Zhu M, Zhi C. Building durable aqueous K-ion capacitors based on MXene family. Nano Res Energy. 2022;1(1):2790. https://doi.org/10.26599/NRE.2022.9120002.

Shahzad F, Alhabeb M, Hatter CB, Anasori B, Hong SM, Koo CM, Gogotsi Y. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science. 2016;353(6304):1137. https://doi.org/10.1126/science.aag2421.

Liu J, Zhang H-B, Sun R, Liu Y, Liu Z, Zhou A, Yu ZZ. Hydrophobic, flexible, and lightweight MXene foams for high-performance electromagnetic-interference shielding. Adv Mater. 2017;29(38):1702367. https://doi.org/10.1002/adma.201702367.

Ma F, Wang J, Yang Y, Wu L, Zhu S, Gelbal SY, Aksun-Guvenc B, Guvenc L. Stability design for the homogeneous platoon with communication time delay. Autom Innov. 2020;3(2):101. https://doi.org/10.1007/s42154-020-00102-4.

Ding L, Li L, Liu Y, Wu Y, Lu Z, Deng J, Wei Y, Caro J, Wang H. Effective ion sieving with Ti3C2Tx MXene membranes for production of drinking water from seawater. Nat Sustain. 2020;3(4):296. https://doi.org/10.1038/s41893-020-0474-0.

Ding L, Wei Y, Wang Y, Chen H, Caro J, Wang H. A two-dimensional lamellar membrane: MXene nanosheet stacks. Angew Chem Int Ed. 2017;56(7):1825. https://doi.org/10.1002/anie.201609306.

Wang J, Chen P, Shi B, Guo W, Jaroniec M, Qiao SZ. A regularly channeled lamellar membrane for unparalleled water and organics permeation. Angew chem Int Ed. 2018;57(23):6814. https://doi.org/10.1002/anie.201801094.

Xie X, Chen C, Zhang N, Tang ZR, Jiang J, Xu YJ. Microstructure and surface control of MXene films for water purification. Nat Sustain. 2019;2(9):856. https://doi.org/10.1038/s41893-019-0373-4.

Fu Q, Zhu R, Song J, Yang H, Chen X. Photoacoustic imaging: contrast agents and their biomedical applications. Adv Mater. 2019;31(6):1805875. https://doi.org/10.1002/adma.201805875.

Liu J, Jiang X, Zhang R, Zhang Y, Wu L, Lu W, Li J, Li Y, Zhang H. MXene-enabled electrochemical microfluidic biosensor: applications toward multicomponent continuous monitoring in whole blood. Adv Funct Mater. 2019;29(6):1807326. https://doi.org/10.1002/adfm.201807326.

Xu B, Zhu M, Zhang W, Zhen X, Pei Z, Xue Q, Zhi C, Shi P. Ultrathin MXene-Micropattern-based field-effect transistor for probing neural activity. Adv Mater. 2016;28(17):3333. https://doi.org/10.1002/adma.201504657.

Liu K, Peng Q, Li K, Chen T. Data-based interpretable modeling for property forecasting and sensitivity analysis of Li-ion battery electrode. Autom Innov. 2022;5(2):121. https://doi.org/10.1007/s42154-021-00169-7.

Coleman JN, Lotya M, O’Neill A, Bergin SD, King PJ, Khan U, Young K, Gaucher A, De S, Smith RJ, Shvets IV, Arora SK, Stanton G, Kim HY, Lee K, Kim GT, Duesberg GS, Hallam T, Boland JJ, Wang JJ, Donegan JF, Grunlan JC, Moriarty G, Shmeliov A, Nicholls RJ, Perkins JM, Grieveson EM, Theuwissen K, McComb DW, Nellist PD, Nicolosi V. Two-dimensional nanosheets produced by liquid exfoliation of layered materials. Science. 2011;331(6017):568. https://doi.org/10.1126/science.1194975.

Mashtalir O, Naguib M, Mochalin VN, Dall’Agnese Y, Heon M, Barsoum MW, Gogotsi Y. Intercalation and delamination of layered carbides and carbonitrides. Nat Commun. 2013;4:1716. https://doi.org/10.1038/ncomms2664.

Naguib M, Unocic RR, Armstrong BL, Nanda J. Large-scale delamination of multi-layers transition metal carbides and carbonitrides “MXenes.” Dalton Trans. 2015;44(20):9353. https://doi.org/10.1039/C5DT01247C.

Mashtalir O, Lukatskaya MR, Zhao MQ, Barsoum MW, Gogotsi Y. Amine-assisted delamination of Nb2C MXene for Li-ion energy storage devices. Adv Mater. 2015;27(23):3501. https://doi.org/10.1002/adma.201500604.

Malaki M, Maleki A, Varma RS. MXenes and ultrasonication. J Mater Chem A. 2019;7(18):10843. https://doi.org/10.1039/C9TA01850F.

Zhang CJ, Pinilla S, McEyoy N, Cullen CP, Anasori B, Long E, Park S-H, Seral-Ascaso A, Shmeliov A, Krishnan D, Morant C, Liu X, Duesberg GS, Gogotsi Y, Nicolosi V. Oxidation stability of colloidal two-dimensional titanium carbides (MXenes). Chem Mater. 2017;29(11):4848. https://doi.org/10.1021/acs.chemmater.7b00745.

Zhang P, Soomro RA, Guan Z, Sun N, Xu B. 3D carbon-coated MXene architectures with high and ultrafast lithium/sodium-ion storage. Energy Storage Mater. 2020;29:163. https://doi.org/10.1016/j.ensm.2020.04.016.

Zhao M-Q, Xie X, Ren CE, Makaryan T, Anasori B, Wang G, Gogotsi Y. Hollow MXene spheres and 3D macroporous MXene frameworks for Na-ion storage. Adv Mater. 2017;29(37):1702410. https://doi.org/10.1002/adma.201702410.

Wu W, Xu J, Tang X, Xie P, Liu X, Xu J, Zhou H, Zhang D, Fan T. Two-dimensional nanosheets by rapid and efficient microwave exfoliation of layered materials. Chem Mater. 2018;30(17):5932. https://doi.org/10.1021/acs.chemmater.8b01976.

Huang X, Wu P. A facile, high-yield, and freeze-and-thaw-assisted approach to fabricate MXene with plentiful wrinkles and its application in on-chip micro-supercapacitors. Adv Funct Mater. 2020;30(12):1910048. https://doi.org/10.1002/adfm.201910048.

Ghidiu M, Barsoum MW. The 110 reflection in X-ray diffraction of MXene films: misinterpretation and measurement via non-standard orientation. J Am Ceram Soc. 2017;100(12):5395. https://doi.org/10.1111/jace.15124.

Wang X, Shen X, Gao Y, Wang Z, Yu R, Chen L. Atomic-scale recognition of surface structure and intercalation mechanism of Ti3C2TX. J Am Chem Soc. 2015;137(7):2715. https://doi.org/10.1021/ja512820k.

Ghassemi H, Harlow W, Mashtalir O, Beidaghi M, Lukatskaya MR, Gogotsi Y, Taheri ML. In situ environmental transmission electron microscopy study of oxidation of two-dimensional Ti3C2 and formation of carbon-supported TiO2. J Mater Chem A. 2014;2(35):14339. https://doi.org/10.1039/C4TA02583K.

Zhao X, Vashisth A, Prehn E, Sun W, Shah S, Habib T, Chen Y, Tan Z, Lutkenhaus J, Radovic M, Green MJ. Antioxidants unlock shelf-stable Ti3C2Tx (MXene) nanosheet dispersions. Matter. 2019;1(2):513. https://doi.org/10.1016/j.matt.2019.05.020.

Zhao X, Vashisth A, Blivin JW, Tan Z, Holta DE, Kotasthane V, Shah SA, Habib T, Liu S, Lutkenhaus JL, Radovic M, Green MJ. pH, Nanosheet concentration, and antioxidant affect the oxidation of Ti3C2Tx and Ti2CTxMXene dispersions. Adv Mater Interfaces. 2020;7(20):2000845. https://doi.org/10.1002/admi.202000845.

Tsai HJ, Su YY, Tseng CC, Hsu WK. Selective modification of aligned carbon nanotubes by N2 plasma and their diode behavior. Rsc Adv. 2018;8(19):10680. https://doi.org/10.1039/C8RA01396A.

Shen C, Wang L, Zhou A, Wang B, Wang X, Lian W, Hu Q, Qin G, Liu X. Synthesis and electrochemical properties of two-dimensional RGO/Ti3C2Tx nanocomposites. Nanomaterials. 2018;8(2):80. https://doi.org/10.3390/nano8020080.

Wang Y, Wang X, Li X, Bai Y, Xiao H, Liu Y, Yuan G. Scalable fabrication of polyaniline nanodots decorated MXene fi lm electrodes enabled by viscous functional inks for high-energy-density asymmetric supercapacitors. Chem Eng J. 2021;405:126664. https://doi.org/10.1016/j.cej.2020.126664.

Li Y, Shao H, Lin Z, Lu J, Liu L, Duployer B, Persson POA, Eklund P, Hultman L, Li M, Chen K, Zha XH, Du S, Rozier P, Chai Z, Raymundo-Pinero E, Taberna PL, Simon P, Huang Q. A general Lewis acidic etching route for preparing MXenes with enhanced electrochemical performance in non-aqueous electrolyte. Nat Mater. 2020;19(8):894. https://doi.org/10.1038/s41563-020-0657-0.

Kamysbayev V, Filatov AS, Hu H, Rui X, Lagunas F, Wang D, Klie RF, Talapin DV. Covalent surface modifications and superconductivity of two-dimensional metal carbide MXenes. Science. 2020;369(6506):979. https://doi.org/10.1126/science.aba8311.

An Y, Tian Y, Wei H, Xi B, Xiong S, Feng J, Qian Y. Porosity- and graphitization-controlled fabrication of nanoporous Silicon@carbon for lithium storage and its conjugation with MXene for Lithium-Metal anode. Adv Funct Mater. 2020;30(9):1908721. https://doi.org/10.1002/adfm.201908721.

Yi R, Zai J, Dai F, Gordin ML, Wang D. Dual conductive network-enabled graphene/Si-C composite anode with high areal capacity for lithium-ion batteries. Nano Energy. 2014;6:211. https://doi.org/10.1016/j.nanoen.2014.04.006.

Ji J, Ji H, Zhang LL, Zhao X, Bai X, Fan X, Zhang F, Ruoff RS. Graphene-encapsulated Si on ultrathin-graphite foam as anode for high capacity lithium-ion batteries. Adv Mater. 2013;25(33):4673. https://doi.org/10.1002/adma.201301530.

Huang A, Ma Y, Peng J, Li L, Chou S, Ramakrishna S, Peng S. Tailoring the structure of silicon-based materials for lithium-ion batteries via electrospinning technology. eScience. 2021;1(2):141. https://doi.org/10.1016/j.esci.2021.11.006.

Li Z, Zhang Y, Liu T, Gao X, Li S, Ling M, Liang C, Zheng J, Lin Z. Silicon anode with high initial coulombic efficiency by modulated trifunctional binder for high-areal-capacity lithium-ion batteries. Adv Energy Mater. 2020;10(20):1903110. https://doi.org/10.1002/aenm.201903110.

Zhou X, Yin YX, Wan LJ, Guo YG. Self-assembled nanocomposite of silicon nanoparticles encapsulated in graphene through electrostatic attraction for lithium-ion batteries. Adv Energy Mater. 2012;2(9):1086. https://doi.org/10.1002/aenm.201200158.

Zhao X, Hayner CM, Kung MC, Kung HH. In-plane vacancy-enabled high-power Si-graphene composite electrode for lithium-ion batteries. Adv Energy Mater. 2011;1(6):1079. https://doi.org/10.1002/aenm.201100426.

Liu J, Zheng Q, Goodman MD, Zhu H, Kim J, Krueger NA, Ning H, Huang X, Liu J, Terrones M, Braun PV. Graphene sandwiched mesostructured Li-ion battery electrodes. Adv Mater. 2016;28(35):7696. https://doi.org/10.1002/adma.201600829.

Chan CK, Peng H, Liu G, McIlwrath K, Zhang XF, Huggins RA, Cui Y. High-performance lithium battery anodes using silicon nanowires. Nat Nanotechnol. 2008;3(1):31. https://doi.org/10.1038/nnano.2007.411.

Hassan FM, Chabot V, Elsayed AR, Xiao X, Chen Z. Engineered Si electrode nanoarchitecture: a scalable postfabrication treatment for the production of next-generation Li-ion batteries. Nano Lett. 2014;14(1):277. https://doi.org/10.1021/nl403943g.

Ma T, Xu H, Yu X, Li H, Zhang W, Cheng X, Zhu W, Qiu X. Lithiation behavior of coaxial hollow nanocables of carbon-silicon composite. ACS Nano. 2019;13(2):2274. https://doi.org/10.1021/acsnano.8b08962.

Jiang M, Jiang M, Gao H, Chen J, Liu W, Ma Y, Luo W, Yang J. Comparison of additives in anode: the case of graphene, MXene, CNTs integration with silicon inside carbon nanofibers. Acta Metall Sin-engl. 2021;34(3):337. https://doi.org/10.1007/s40195-020-01153-6.

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (No. 52102470), the Natural Science Foundation of Jiangsu Province (No. BK20200047), General Project of Natural Science Research in Jiangsu Universities (22KJB15003), Scientific Research Project for Doctor Degree Teachers of Jiangsu Normal University (21XSRX003).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, P., Zhu, ZH., Zhang, W. et al. Shearing-force-driven delamination of waste residue into oxidatively stable MXene composites for high-performance Si anode. Rare Met. 42, 2226–2237 (2023). https://doi.org/10.1007/s12598-022-02182-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-02182-z