Abstract

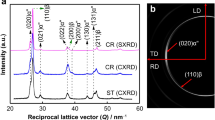

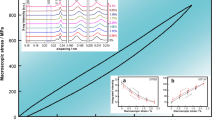

The phase transformations during thermomechanical processing can be employed to optimize mechanical properties of β-type Ti alloys. However, such understandings are still lacking for the alloy consisting of dual β + α″ phases in solution-treated and quenched state. In this paper, the phase transformations in a Ti38Nb model alloy subjected to different thermomechanical processing were investigated by using synchrotron X-ray diffraction (SXRD) experiments, and their influence on the Young’s modulus was discussed. The results indicated that high-density dislocations introduced by cold rolling still existed after annealing at temperatures lower than 573 K, which can decrease the martensitic transformation start temperature to below room temperature. With annealing temperatures increasing, the α″ → β, β → ωiso, and β → α phase transformations occurred successively. At annealing temperature of 473 K, the specimen consisted of a trace of α″ and ω phases as well as dominant β phase which was kept to room temperature by the high density of dislocations, rather than by the chemical stabilization. As a result, an ultralow Young’s modulus of 25.9 GPa was realized. Our investigation not only provides in-depth understandings of the phase transformations during thermomechanical processing of β-type Ti alloys, but also sheds light on designing biomedical Ti alloys with ultralow Young’s modulus.

Graphic abstract

抽象

β钛合金在热机械处理过程中的相变可以用来优化其机械性能。然而对于固溶态为β + α″的双相合金, 其相变和性能关系的研究尚且缺乏。本文利用同步辐射X射线技术研究了Ti38Nb合金在不同热机械处理状态下的相组成, 并讨论了其对杨氏模量的影响规律。结果表明冷轧引入的高密度位错在低于573 K退火后仍然存在, 这可以将马氏体相变点降至室温以下。随退火温度的升高, α″ → β, β → ωiso和β → α相变依次发生。当退火温度为473 K时, 样品中主要由β相组成并含有少量α″和ω相。这其中β相是通过高密度位错保留至室温而非化学成分稳定化。因此合金可以实现25.9 GPa的超低杨氏模量。本研究不但对β钛合金在热机械处理过程中的相变行为提供了深入理解, 而且为超低杨氏模量生物医用钛合金的开发提供了新思路.

Similar content being viewed by others

References

Niinomi M, Nakai M, Hieda J. Development of new metallic alloys for biomedical applications. Acta Biomater. 2012;8(11):3888.

Geetha M, Singh AK, Asokamani R, Gogia AK. Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci. 2009;54(3):397.

Chen LY, Cui YW, Zhang LC. Recent development in beta titanium alloys for biomedical applications. Metals. 2020;10(9):1139.

Niinomi M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J Mech Behav Biomed Mater. 2008;1(1):30.

Pellizzari M, Jam A, Tschon M, Fini M, Lora C, Benedetti M. A 3D-printed ultra-low Young’s modulus β-Ti alloy for biomedical applications. Materials. 2020;13(12):2792.

Sumner DR, Turner TM, Igloria R, Urban RM, Galante JO. Functional adaptation and ingrowth of bone vary as a function of hip implant stiffness. J Biomech. 1998;31(10):909.

Nagoshi T, Yasuda T, Otaki N, Tahara M, Hosoda H, Sone M. Evaluation of the shape memory effect by micro-compression testing of single crystalline Ti-27Nb Ni-free alloy. Materials. 2020;13(1):110.

Zhao X, Niinomi M, Nakai M, Hieda J. Beta type Ti–Mo alloys with changeable Young’s modulus for spinal fixation applications. Acta Biomater. 2012;8(5):1990.

Zhou YL, Niinomi M. Microstructures and mechanical properties of Ti–50mass% Ta alloy for biomedical applications. J Alloys Compd. 2008;466(1):535.

Hanada S, Masahashi N, Jung TK, Miyake M, Sato YS, Kokawa H. Effect of swaging on Young's modulus of β Ti–33.6Nb–4Sn alloy. J Mech Behav Biomed Mater. 2014;32:310.

Meng Q, Wang K, Li H, Guo S, Wei F, Qi J, Sui Y, Zhao X. Single crystal shear moduli of β-phase stabilized by thermomechanical treatment in TiNbSn alloys with ultralow elastic modulus. Mater Lett. 2021;285:129103.

Meng Q, Guo S, Liu Q, Hu L, Zhao X. A β-type TiNbZr alloy with low modulus and high strength for biomedical applications. Prog Nat Sci. 2014;24(2):157.

Marczewski M, Miklaszewski A, Maeder X, Jurczyk M. Crystal structure evolution, microstructure formation, and properties of mechanically alloyed ultrafine-grained Ti-Zr-Nb alloys at 36≤Ti≤70 (at%). Materials. 2020;13(3):587.

Niinomi M. Fatigue performance and cyto-toxicity of low rigidity titanium alloy, Ti–29Nb–13Ta–4.6Zr. Biomaterials. 2003;24(16):2673.

Li BQ, Li CL, Wang ZX, Lu X. Preparation of Ti–Nb–Ta–Zr alloys for load-bearing biomedical applications. Rare Met. 2019;38(6):571.

Hao YL, Li SJ, Sun SY, Zheng CY, Yang R. Elastic deformation behaviour of Ti–24Nb–4Zr–79Sn for biomedical applications. Acta Biomater. 2007;3(2):277.

Li X, Ye S, Yuan X, Yu P. Fabrication of biomedical Ti-24Nb-4Zr-8Sn alloy with high strength and low elastic modulus by powder metallurgy. J Alloys Compd. 2019;772:968.

Banerjee D, Williams JC. Perspectives on titanium science and technology. Acta Mater. 2013;61(3):844.

Moffat DL, Larbalestier DC. The compctition between martensite and omega in quenched Ti-Nb alloys. Metall Trans A. 1988;19(7):1677.

Kim HY, Ikehara Y, Kim JI, Hosoda H, Miyazaki S. Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys. Acta Mater. 2006;54(9):2419.

Qu WT, Gong H, Wang J, Nie YS, Li Y. Martensitic transformation, shape memory effect and superelasticity of Ti–xZr–(30–x)Nb–4Ta alloys. Rare Met. 2019;38(10):965.

Nejezchlebová J, Janovská M, Sedlák P, Šmilauerová J, Stráský J, Janeček M, Seiner H. Elastic constants of β-Ti15Mo. J Alloys Compd. 2019;792:960.

Devaraj A, Nag S, Srinivasan R, Williams REA, Banerjee S, Banerjee R, Fraser HL. Experimental evidence of concurrent compositional and structural instabilities leading to ω precipitation in titanium–molybdenum alloys. Acta Mater. 2012;60(2):596.

Ng HP, Devaraj A, Nag S, Bettles CJ, Gibson M, Fraser HL, Muddle BC, Banerjee R. Phase separation and formation of omega phase in the beta matrix of a Ti–V–Cu alloy. Acta Mater. 2011;59(8):2981.

Hao YL, Yang R, Niinomi M, Kuroda D, Zhou YL, Fukunaga K, Suzuki A. Young’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6Zr in relation to α″ martensite. Metall Mater Trans A. 2002;33(10):3137.

Ho WF, Ju CP, Lin JH. Structure and properties of cast binary Ti-Mo alloys. Biomaterials. 1999;20(22):2115.

Tane M, Akita S, Nakano T, Hagihara K, Umakoshi Y, Niinomi M, Mori H, Nakajima H. Low Young’s modulus of Ti–Nb–Ta–Zr alloys caused by softening in shear moduli c′ and c44 near lower limit of body-centered cubic phase stability. Acta Mater. 2010;58(20):6790.

Abdel-Hady M, Hinoshita K, Morinaga M. General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scr Mater. 2006;55(5):477.

Zhang K, Dong HB, Jiang ZY, Shi S, Liu HX. Effects of cold-deformation and aging process on microstructure and properties of TB8 titanium alloy. Chin J Rare Met. 2019;43(9):904.

Sun F, Hao YL, Nowak S, Gloriant T, Laheurte P, Prima F. A thermo-mechanical treatment to improve the superelastic performances of biomedical Ti–26Nb and Ti–20Nb–6Zr (at%) alloys. J Mech Behav Biomed Mater. 2011;4(8):1864.

Kuroda PAB, Lourenço ML, Correa DRN, Grandini CR. Thermomechanical treatments influence on the phase composition, microstructure, and selected mechanical properties of Ti–20Zr–Mo alloys system for biomedical applications. J Alloys Compd. 2020;812:152108.

Li HJ, Yu Y, Song XY, Ye WJ, Hui SX. Thermal deformation behavior and processing map of a new type of Ti-6554 alloy. Chin J Rare Met. 2020;44(5):462.

Sheremetyev V, Kudryashova A, Dubinskiy S, Galkin S, Prokoshkin S, Brailovski V. Structure and functional properties of metastable beta Ti-18Zr-14Nb (at.%) alloy for biomedical applications subjected to radial shear rolling and thermomechanical treatment. J Alloys Compd. 2018;737:678.

Mantani Y, Tajima M. Phase transformation of quenched α″ martensite by aging in Ti–Nb alloys. Mater Sci Eng A. 2006;438–440:315.

Lopes ESN, Cremasco A, Afonso CRM, Caram R. Effects of double aging heat treatment on the microstructure, Vickers hardness and elastic modulus of Ti–Nb alloys. Mater Charact. 2011;62(7):673.

Ping DH, Cui CY, Yin FX, Yamabe-Mitarai Y. TEM investigations on martensite in a Ti–Nb-based shape memory alloy. Scr Mater. 2006;54(7):1305.

Zhu Y, Meng Q, Guo S, Qi L, Xiao W, Ping D, Zhao X. Anomalous phase stability of surface and interior in a metastable Ti-Nb-Zr alloy. Mater Lett. 2016;169:210.

Zhao CH, Kisslinger K, Huang XJ, Lu M, Camino F, Lin CH, Yan HF, Nazaretski E, Chu Y, Ravel B, Liu MZ, Chen-Wiegart YCK. Bi-continuous pattern formation in thin films via solid-state interfacial dealloying studied by multimodal characterization. Mater Horizons. 2019;6(10):1991.

Zhu ZW, Xiong CY, Wang J, Li RG, Ren Y, Wang YD, Li Y. In situ synchrotron X-ray diffraction investigations of the physical mechanism of ultra-low strain hardening in Ti-30Zr-10Nb alloy. Acta Mater. 2018;154:45.

Zhao C, Wada T, De Andrade V, Gürsoy D, Kato H, Chen-Wiegart YCK. Imaging of 3D morphological evolution of nanoporous silicon anode in lithium ion battery by X-ray nano-tomography. Nano Energy. 2018;52:381.

Lin CH, Topsakal M, Sun K, Bai J, Zhao C, Dooryhee E, Northrup P, Gan H, Lu D, Stavitski E, Chen-Wiegart YCK. Operando structural and chemical evolutions of TiS2 in Na-ion batteries. J Mater Chem A. 2020;8(25):12339.

Prescher C, Prakapenka VB. DIOPTAS: a program for reduction of two-dimensional X-ray diffraction data and data exploration. High Press Res. 2015;35(3):223.

Chen W, Sun Q, Xiao L, Sun J. Deformation-induced grain refinement and amorphization in Ti-10V-2Fe-3Al alloy. Metall Mater Trans A. 2012;43(1):316.

Yang Y, Li GP, Cheng GM, Li YL, Yang K. Multiple deformation mechanisms of Ti–22.4Nb–0.73Ta–2.0Zr–1.34O alloy. Appl Phys Lett. 2009;94(6):061901.

Meng Q, Guo S, Ren X, Xu H, Zhao X. Possible contribution of low shear modulus C44 to the low Young’s modulus of Ti-36Nb-5Zr alloy. Appl Phys Lett. 2014;105(13):131907.

Guo S, Meng Q, Zhao X, Wei Q, Xu H. Design and fabrication of a metastable β-type titanium alloy with ultralow elastic modulus and high strength. Sci Rep. 2015;5:14688.

Meng Q, Li H, Wang K, Guo S, Wei F, Qi J, Sui Y, Shen B, Zhao X. In situ synchrotron X-ray diffraction investigations of the nonlinear deformation behavior of a low modulus β-Type Ti36Nb5Zr alloy. Metals. 2020;10(12):1619.

Matsumoto H, Watanabe S, Hanada S. Beta TiNbSn alloys with low Young’s modulus and high strength. Mater Trans. 2005;46(5):1070.

Tane M, Akita S, Nakano T, Hagihara K, Umakoshi Y, Niinomi M, Nakajima H. Peculiar elastic behavior of Ti–Nb–Ta–Zr single crystals. Acta Mater. 2008;56(12):2856.

Al-Zain Y, Kim HY, Hosoda H, Nam TH, Miyazaki S. Shape memory properties of Ti–Nb–Mo biomedical alloys. Acta Mater. 2010;58(12):4212.

Otsuka K, Ren X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog Mater Sci. 2005;50(5):511.

Meng Q, Zhang J, Huo Y, Sui Y, Zhang J, Guo S, Zhao X. Design of low modulus β-type titanium alloys by tuning shear modulus C44. J Alloys Compd. 2018;745:579.

Zheng Y, Alam T, Banerjee R, Banerjee D, Fraser HL. The influence of aluminum and oxygen additions on intrinsic structural instabilities in titanium-molybdenum alloys. Scr Mater. 2018;152:150.

Choudhuri D, Zheng Y, Alam T, Shi R, Hendrickson M, Banerjee S, Wang Y, Srinivasan SG, Fraser H, Banerjee R. Coupled experimental and computational investigation of omega phase evolution in a high misfit titanium-vanadium alloy. Acta Mater. 2017;130:215.

Bönisch M, Calin M, Waitz T, Panigrahi A, Zehetbauer M, Gebert A, Skrotzki W, Eckert J. Thermal stability and phase transformations of martensitic Ti-Nb alloys. Sci Technol Adv Mater. 2013;14(5):055004.

Nag S, Banerjee R, Srinivasan R, Hwang JY, Harper M, Fraser HL. ω-Assisted nucleation and growth of α precipitates in the Ti–5Al–5Mo–5V–3Cr–0.5Fe β titanium alloy. Acta Mater. 2009;57(7):2136.

Guo S, Zhang J, Cheng X, Zhao X. A metastable β-type Ti–Nb binary alloy with low modulus and high strength. J Alloys Compd. 2015;644:411.

Guo S, Shi Y, Liu G, Wu R, Luo R, Peng CT, Meng Q, Cheng X, Zhao X. Design and fabrication of a (β+α′′) dual-phase Ti-Nb-Sn alloy with linear deformation behavior for biomedical applications. J Alloys Compd. 2019;805:517.

Guo S, Meng Q, Liao G, Hu L, Zhao X. Microstructural evolution and mechanical behavior of metastable β-type Ti–25Nb–2Mo–4Sn alloy with high strength and low modulusMicrostructural evolution and mechanical behavior of metastable β-type Ti–25Nb–2Mo–4Sn alloy with high strength and low modulus. Prog Nat Sci. 2013;23(2):174.

Meng Q, Liu Q, Guo S, Zhu Y, Zhao X. Effect of thermo-mechanical treatment on mechanical and elastic properties of Ti–36Nb–5Zr alloy. Prog Nat Sci. 2015;25(3):229.

Bönisch M, Panigrahi A, Calin M, Waitz T, Zehetbauer M, Skrotzki W, Eckert J. Thermal stability and latent heat of Nb–rich martensitic Ti-Nb alloys. J Alloys Compd. 2017;697:300.

Acknowledgements

This work was financially supported by the Fundamental Research Funds for the Central Universities (No. 2017QNA04). Qing-Kun Meng thanks Prof. Yu-chen Karen Chen-Wiegart at Stony Brook University and Dr. Jianming Bai, Dr. Hui Zhong and Dr. Sanjit Ghose at National Synchrotron Light Source II for their assistance in the synchrotron experiments. This research used 28-ID-2 (XPD) beamline of the National Synchrotron Light Source II, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Brookhaven National Laboratory under Contract No. DE-SC0012704.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Meng, QK., Li, H., Zhao, CH. et al. Synchrotron X-ray diffraction characterization of phase transformations during thermomechanical processing of a Ti38Nb alloy. Rare Met. 40, 3269–3278 (2021). https://doi.org/10.1007/s12598-021-01763-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-021-01763-8