Abstract

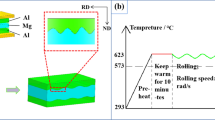

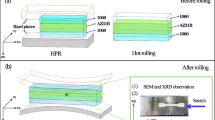

The corrugated + flat rolling (CFR) and traditional rolling (TR) methods were used to prepare Mg/Al clad plates using AZ31B Mg and 5052 Al plates, and the interface morphologies and mechanical properties of the resulting clad plates were compared. Examination of the microstructures of the plates showed that the TRed Mg/Al clad plate presented a straight interface, while a corrugated interface containing fractured intermetallic particulates was observed for the CFRed plate due to the inhomogeneous strain induced by the corrugated roller. During the CFR process, the corrugated roller can accelerate the rupture of the substrate work-hardening layers and facilitate the mutual extrusion of fresh metals to enhance the interface bonding. Compared with the traditional basal texture of the Mg alloy, the CFR process can change the texture morphology, thereby enhancing the plastic deformation ability of the Mg plate. Tensile tests showed that the CFRed Mg/Al clad plate exhibited a higher ultimate tensile strength (UTS, 316 MPa), which was ~ 8% higher than that of the TRed plate (293 MPa). In addition, the bending curve of the CFRed clad plate was smooth and there was no stress sudden drop phenomenon in the bending process. The higher UTS and excellent bending properties of the CFRed clad plate could be attributed to the enhanced coordinated deformation ability of the substrates induced by the corrugated interface, grain refinement, and the change in the Mg alloy texture morphology.

Graphic abstract

Similar content being viewed by others

References

Yang XW, Feng WY, Li WY, Dong XR, Xu YX, Chu Q, Yao ST. Microstructure and properties of probeless friction stir spot welding of AZ31 magnesium alloy joints. Trans Nonferrous Met Soc. 2019;29(11):2300.

Liu JB, Zhang K, Han JT, Li XG, Li YJ, Ma ML, Yuan JW, Shi GL. Microstructure and texture evolution of Mg–7Y–1Nd–0.5Zr alloy sheets with different rolling temperatures. Rare Met. 2020;39(11):1273.

Tang JW, Chen L, Zhao GQ, Zhang CS, Yu JQ. Study on Al/Mg/Al sheet fabricated by combination of porthole die co-extrusion and subsequent hot rolling. J Alloy Compd. 2019;784:727.

Li MF, Zhu ZQ, Zhang YF, Pan D, Xiao QK. AZ31Mg/6061Al ultrasonic welding and interface performance analysis. Chin J Rare Met. 2019;43(6):577.

Ding HL, Zhang P, Cheng GP, Kamado S. Effect of calcium addition on microstructure and texture modification of Mg rolled sheets. Trans Nonferrous Met Soc. 2015;25(9):2875.

Li XB, Yang Y, Xu YS, Zu GY. Deformation behavior and crack propagation on interface of Al/Cu laminated composites in uniaxial tensile test. Rare Met. 2018;39(3):296.

Naseri M, Reihanian M, Borhani E. Bonding behavior during cold roll-cladding of tri-layered Al/brass/Al composite. J Manuf Process. 2016;24:125.

Hoseini Athar MM, Tolaminejad B. Weldability window and the effect of interface morphology on the properties of Al/Cu/Al laminated composites fabricated by explosive welding. Mater Des. 2015;86:516.

Jiang J, Liu Y, Xiao G, Wang Y, Ju Y. Effect of pass reduction on microstructure, mechanical properties and texture of hot-rolled 7075 alloy. Mater Charact. 2019;147:324.

Quadir MZ, Najafzadeh N, Munroe PR. Variations in through-thickness recrystallization and grain growth textures in the Al layers in ARB-processed Al/Al(0.3% Sc) composite sheets. Mater Des. 2016;93:467.

Li XB, Zu GY, Wang P. Asymmetry in interface and bending property of Al/Cu/Al bimetallic laminates. Rare Met. 2014;33(5):556.

Li Y, Wang QP, Gao GJ, Li JD, Wang ZD, Xu GM. Texture evolution and mechanical properties of Al–Mg–Si alloys at different intermediate annealing temperatures. Rare Met. 2019;38(10):937.

Li G, Yang W, Jiang W, Guan F, Jiang H, Wu Y, Fan Z. The role of vacuum degree in the bonding of Al/Mg bimetal prepared by a compound casting process. J Mater Process Technol. 2019;265:112.

Habila W, Azzeddine H, Mehdi B, Tirsatine K, Baudin T, Helbert AL, Brisset F, Gautrot S, Mathon MH, Bradai D. Investigation of microstructure and texture evolution of a Mg/Al laminated composite elaborated by accumulative roll bonding. Mater Charact. 2019;147:242.

Wu Y, Xin YC, Xia XS, Feng B, Wang YB, Zhao ZD. Influence of annealing treatments on microstructure and mechanical properties of an extruded Mg AZ31/Al 7050 laminate. Acta Metall Sin Engl. 2018;32(2):227.

Zhu C, Sun L, Gao W, Li G, Cui J. The effect of temperature on microstructure and mechanical properties of Al/Mg lap joints manufactured by magnetic pulse welding. J Mater Res Technol. 2019;8(3):3270.

Zeng XY, Wang YX, Li XQ, Li XJ, Zhao TJ. Effect of inert gas-shielding on the interface and mechanical properties of Mg/Al explosive welding composite plate. J Manuf Process. 2019;45:166.

Wei AL, Liu XH, Dong L, Liang W. Binding property of Al/Mg/Al thin plates fabricated by one-pass hot rolling with different reduction ratios, temperatures and annealing treatments. Rare Met. 2015;37(2):136.

Zhang TT, Wang WX, Zhang W, Wei Y, Cao XQ, Yan ZF, Zhou J. Microstructure evolution and mechanical properties of an AA6061/AZ31B alloy plate fabricated by explosive welding. J Alloy Compd. 2018;735:1759.

Chen ZQ, Wang DY, Cao XQ, Yang WW, Wang WX. Influence of multi-pass rolling and subsequent annealing on the interface microstructure and mechanical properties of the explosive welding Mg/Al composite plates. Mater Sci Eng A. 2018;723:97.

Liu WS, Long LP, Ma YZ, Wu L. Microstructure evolution and mechanical properties of Mg/Al diffusion bonded joints. J Alloy Compd. 2015;643:34.

Nie HH, Liang W, Chen HS, Zheng LW, Chi CZ, Li XR. Effect of annealing on the microstructures and mechanical properties of Al/Mg/Al laminates. Mater Sci Eng A. 2018;732:6.

Wang T, Li S, Ren ZK, Han JC, Huang QX. A novel approach for preparing Cu/Al laminated composite based on corrugated roll. Mater Lett. 2019;234(1):79.

Wang T, Li S, Ren ZK, Jia Y, Fu WS, Guo M, Ma XC, Han JC. Microstructure characterization and mechanical property of Mg/Al laminated composite prepared by the novel approach: corrugated + flat rolling (CFR). Metals. 2019;9(6):690.

Wang T, Wang YL, Bian LP, Huang QX. Microstructural evolution and mechanical behavior of Mg/Al laminated composite sheet by novel corrugated rolling and flat rolling. Mater Sci Eng A. 2019;765:138318.

Zhang N, Wang WX, Cao XQ, Wu JQ. The effect of annealing on the interface microstructure and mechanical characteristics of AZ31B/AA6061 composite plates fabricated by explosive welding. Mater Des. 2015;65:1100.

Nie HH, Liang W, Zheng LW, Ren XX, Chi CZ. The microstructure, texture and mechanical properties of the rolled Al/Mg/Al clad sheets. J Mater Eng Perform. 2016;25(11):4695.

Nie HH, Hao XW, Chen HS, Kang XP, Wang TL, Mi YJ, Liang W. Effect of twins and dynamic recrystallization on the microstructures and mechanical properties of Ti/Al/Mg laminates. Mater Des. 2019;181:107948.

Wan G, Wu BL, Zhang YD, Sha GY, Esling C. Anisotropy of dynamic behavior of extruded AZ31 magnesium alloy. Mater Sci Eng A. 2010;527(12):2915.

Tan JC, Tan MJ. Dynamic continuous recrystallization characteristics in two stage deformation of Mg–3Al–1Zn alloy sheet. Mater Sci Eng A. 2003;339(1):124.

Li XB, Zu GY, Wang P. Effect of strain rate on tensile performance of Al/Cu/Al laminated composites produced by asymmetrical roll bonding. Mater Sci Eng A. 2013;575:61.

Yousefi Mehr V, Toroghinejad MR, Rezaeian A. Mechanical properties and microstructure evolutions of multilayered Al–Cu composites produced by accumulative roll bonding process and subsequent annealing. Mater Sci Eng A. 2014;601:40.

Hosseini SA, Hosseini M, Danesh Manesh H. Bond strength evaluation of roll bonded bi-layer copper alloy strips in different rolling conditions. Mater Des. 2011;32(1):76.

Chu Q, Zhang M, Li J, Yan C. Experimental and numerical investigation of microstructure and mechanical behavior of titanium/steel interfaces prepared by explosive welding. Mater Sci Eng A. 2017;689:323.

Kudo S, Yokoyama S, Shimoyama K, Kaneko S, Fujita F. Effect of dimple patterning conditions of periodical straining rolling on microstructures and mechanical properties of AZ31 sheets. Mater Sci Eng A. 2017;680:75.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. U1710254, 51904205, 51904206), Science and Technology Foundation of State Key laboratory (No. 6142909180205), Taiyuan City Science and Technology Major Projects (No. 170203), Shanxi Province Science and Technology Major Projects (Nos. MC2016-01, 20181101008), the Natural Science Foundation of Shanxi Province (Nos. 201801D221221, 201801D221130 and 201801D221346), Key Projects of Shanxi Province Key Research and Development Plan (No. 201703D111003) and the China Postdoctoral Science Foundation (Nos. 2018M641680, 2018M641681).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, S., Luo, C., Bashir, MU. et al. Interface structures and mechanical properties of corrugated + flat rolled and traditional rolled Mg/Al clad plates. Rare Met. 40, 2947–2955 (2021). https://doi.org/10.1007/s12598-020-01646-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01646-4