Abstract

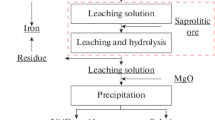

In this work, a novel approach of leaching valuable metals, such as niobium, yttrium and cerium, from a niobium-bearing ore of low grade by roasting KHSO4–H2SO4 system was experimentally studied. Through the work, the effects of roasting temperature, roasting time, mass ratio of agents to ore and the types of leaching agents on the extraction of Nb, Y and Ce were investigated, and the roasting KHSO4–H2SO4–ore system was thought as an effective method to extract these valuable metals. It was found that the recovery of Nb, Y and Ce can, respectively, reach 90.20%, 97.22% and 98.41% in condition of roasting temperature of 300 °C, roasting time of 2 h, mass ratio of KHSO4-to-H2SO4 to ore of 0.5:1:1, particle size of − 74 μm (~ 95%), leaching solution of oxalic acid (30 g·L−1), leaching temperature of 90 °C and leaching liquid-to-solid ratio of 5:1. The leaching kinetics of the calcined Nb-bearing ore in oxalic acid solution was successfully modeled by chemical reaction model, and the apparent activity energy was obtained to be 14.16 kJ·mol−1. The results generated from this work will provide the fundamentals for extracting Nb, Y and Ce from a niobium-bearing ore of low grade and have potential applications value in future.

Similar content being viewed by others

References

He J. Progress and prospect of tantalum and niobium industry. Chin J Rare Met. 2003;27(1):23.

Singh N, Deo MN, Roy SB. Optical investigation of niobium properties: electrical- and physical constants. Physica C (Amsterdam, Neth). 2017;539:1.

Aimone P, Yang M. Niobium alloys for the chemical process industry. Int J Refract Met Hard Mater. 2018;71:335.

Deng L, Lu S, Tang B. High temperature creep behavior of Nb–Cr–Mo aloy. Chin J Rare Met. 2019;43(06):598.

Yu C, Xiao L, Zhao X, Liu J, Guo L, Cai Z. Microstructure and mechanical properties of Nb–20Ti–16Al alloy with carbon addition. Chin J Rare Met. 2017;41(9):980.

Osorio AG, Souza D, dos Passos T, Dalpiaz L, Aires T. Effect of niobium addition on the flux of submerged arc welding of low carbon steels. J Mater Process Technol. 2019;266:46.

Smith CJ, Weinberger CR, Thompson GB. Phase stability and microstructural formations in the niobium carbides. J Eur Ceram Soc. 2018;38(15):4850.

Holubová J, Černošek Z, Hejda P. The influence of niobium on the structure of Nb2O5–ZnO–P2O5 glasses. J Non-Cryst Solids. 2018;502:35.

Ju H, Jia P, Xu J, Yu L, Asempah I, Geng Y. Crystal structure and high temperature tribological behavior of niobium aluminum nitride films. Materialia. 2018;3:202.

Ferraz NP, Nogueira AE, Marcos FCF, Machado VA, Rocca RR, Assaf EM, Asencios YJO. CeO2–Nb2O5 photocatalysts for degradation of organic pollutants in water. Rare Met. 2020;39(3):230.

Chen JY. Handbook of Hydrometallurgy. Beijing: Metallurgical Industry Press; 2005. 1203.

Gupta C, Suri A. Extractive Metallurgy of Niobium. London: CRC Press; 1994. 98.

He J, Zhang Z, Xu Z. Hydrometallurgical extraction of Ta and Nb in China. Rare Met Mater Eng. 1998;27(1):9.

Brocchi E, Moura F. Chlorination methods applied to recover refractory metals from tin slags. Miner Eng. 2008;21(2):150.

El-Hussaini OM, Mahdy MA. Sulfuric acid leaching of Kab Amiri niobium-tantalum bearing minerals, Central Eastern Desert, Egypt. Hydrometallurgy. 2002;64(3):219.

Krismer B, Hoppe A. Process for recovering niobium and/or tantalum compounds from such ores further containing complexes of uranium, thorium, titanium and/or rare earth metals. U.S. Patent 4446116. 1984.

Bock R. Handbook of Decomposition methods in analytical chemistry. Translated and revised by LL Marr. T.&A. TBS The Book Service Ltd: Constable, Edinburgh, Great Britain, 1979: 196.

Gao W, Wen J, Wu B, Shang H. Metallurgical process of niobium-tantalum extraction. Chin J Rare Met. 2016;40(1):77.

El-Hussaini OM. Extraction of Niobium and Tantalum Elements from Some Egyptian Ore Materials. Cairo: Cairo University; 1996. 122.

Zhou H, Zheng S, Zhang Y, Yi D. A kinetic study of the leaching of a low-grade niobium-tantalum ore by concentrated KOH solution. Hydrometallurgy. 2005;80(3):170.

Deblonde GJ-P, Weigel V, Bellier Q, Houdard R, Delvallée F, Bélair S, Beltrami D. Selective recovery of niobium and tantalum from low-grade concentrates using a simple and fluoride-free process. Sep Purif Technol. 2016;162:180.

Zhou HM, Zheng SL, Zhang Y. Leaching of a low-grade refractory tantalum-niobium ore by KOH sub-molten salt. The Chin J Process Eng. 2003;3(5):459.

Wang X, Zheng S, Xu H, Zhang Y. Leaching of niobium and tantalum from a low-grade ore using a KOH roast-water leach system. Hydrometallurgy. 2009;98(3–4):219.

El-Hazek MN, Amer TE, Issa RM, Abu El-Azm MG, Omar SA, El-Hady SM. Characterization and breakdown of south Gabal El-A’urf polymineralized ore material. Eurasian Chemico-Technol J. 2016;11(2):149.

Wu B, Shang H, Wen J. Leaching of niobium from low-grade refractory tantalum-niobium bearing minerals. Chin J Rare Met. 2013;37(5):791.

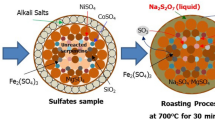

Gao W, Wen J, Wu B, Shang H. Extraction of niobium, yttrium and cerium from a low-grade niobium-bearing ore by roasting (NH4)2SO4–Na2SO4–H2SO4 system. Rare Met. 2014;33(6):754.

Levenspiel O. Chemical Reaction Engineering. 3rd ed. New York: John Wiley and Sons; 1972. 566.

Demirkiran N. A study on dissolution of ulexite in ammonium acetate solutions. Chem Eng J. 2008;141(1–3):180.

Gao W, Wen J, Li ZB. Dissolution kinetics of magnesium from calcined serpentine in NH4Cl solution. Ind Eng Chem Res. 2014;53(19):7947.

Wu B, Liao B, Liu X, Wen J. A study on electrochemical fundamentals and kinetics of bioleaching of Chalcocite. Chin J Rare Met. 2019;43(12):1332.

Acknowledgements

This work was financially supported by China Postdoctoral Science Foundation (No. 2014M560922).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, WC., Wen, JK., Wu, B. et al. A novel approach to extract Nb, Y and Ce from a niobium-bearing ore of low grade by roasting KHSO4–H2SO4 system. Rare Met. 40, 1979–1986 (2021). https://doi.org/10.1007/s12598-020-01435-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01435-z