Abstract

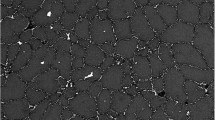

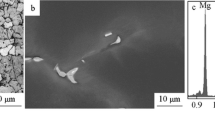

An Al–Cu–Mg–Zr alloy, which obtained different homogenization cooling rates by changing the heat-treated sample size, was compressed to various strains at the deformation temperature of 300 ºC and strain rate of 0.01 s−1. The results showed that the homogenization cooling rate had strong effects on the hot deformation behavior of the alloy. The flow stress and relative dynamic softening rate of the alloy were significantly higher under a high cooling rate (HCR) than those under a low cooling rate (LCR). Furthermore, based on X-ray diffraction, scanning electron microscopy, transmission electron microscopy, and thermodynamic equilibrium phase calculation, the substructure evolution in the grain interior, morphology, and spatial distribution of the precipitates were studied to determine the differences in the flow softening mechanism. The main softening mechanism could be summarized as dynamic recovery and precipitation coarsening for the LCR alloy and dynamic precipitation for the HCR alloy.

Similar content being viewed by others

References

Lam DF, Menzemer CC, Srivatsan TS. A study to evaluate and understand the response of aluminum alloy 2026 subjected to tensile deformation. Mater Des. 2010;31(1):166.

Li Y, Liu ZY, Lin LH, Peng JT, Ning AL. Deformation behavior of an Al–Cu–Mg–Mn–Zr alloy during hot compression. J Mater Sci. 2011;46(11):3708.

Liu XY, Pan QL, He YB, Li WB, Liang WJ, Yin ZM. Flow behavior and microstructural evolution of Al–Cu–Mg–Ag alloy during hot compression deformation. Mater Sci Eng A. 2009;500(1–2):150.

Banerjee S, Robi PS, Srinivasn A, Kumar LP. High temperature deformation behavior of Al–Cu–Mg alloys micro-alloyed with Sn. Mater Sci Eng A. 2010;527(10):2498.

Li HZ, Wang HJ, Liang XP, Liu Y, Zhang XM. Hot deformation and processing map of 2519A aluminum alloy. Mater Sci Eng A. 2011;528(3):1548.

Huang XD, Zhang H, Han Y, Wu WX, Chen JH. Hot deformation behavior of 2026 aluminum alloy during compression at elevated temperature. Mater Sci Eng A. 2010;527(3):485.

Cepda-jimenez CM, Ruano OA, Carsi M, Carrene F. Study of hot deformation of an Al–Cu–Mg alloy using processing maps and microstructural characterization. Mater Sci Eng A. 2012;552(9):530.

Ou L, Zheng ZQ, Nie YF, Jian HG. Hot deformation behavior of 2060 alloy. J. Alloys Compd. 2015;648:681.

Chen L, Zhao GQ, Gong J, Chen XX, Chen MM. Hot deformation behaviors and processing maps of 2024 aluminum alloy in as-cast and homogenized states. J Mater Eng Perform. 2015;24(12):5002.

Li PW, Li HZ, Huang L, Liang XP, Zhu ZX. Characterization of hot deformation behavior of AA2014 forging aluminum alloy using processing map. Trans Nonferrous Met Soc China. 2017;27(8):1677.

Zang WL, Xaio DH, Li T, Du JD, Ding DY. Microstructure and mechanical properties of two-stage aged Al-Cu-Mg-Ag-Sm alloy. Rare Met. 2018;38(1):42.

Wouters P, Verlinden B, Mcqueen HJ, Aernoudt E, Delaeyl L. Effect of homogenization and precipitation treatments on the hot workability of an aluminium alloy AA2024. Mater Sci Eng, A. 1990;123(2):239.

Verlinden B, Wouters P, Mcqueen HJ, Aernoudt E, Delaey L. Effect of different homogenization treatments on the hot workability of aluminium alloy AA2024. Mater Sci Eng A. 1990;123(2):229.

Mcqueen HJ. Development of dynamic recrystallization theory. Mater Sci Eng, A. 2004;387(1):203.

Zhang H, Chen R, Huang XD, Chen JH. Microstructural evolution of 2026 aluminum alloy during hot compression and subsequent heat treatment. Trans Nonferrous Met Soc China. 2011;21(5):955.

Gavgali M, Aksakal B. Effects of various homogenisation treatments on the hot workability of ingot aluminium alloy AA2014. Mater Sci Eng A. 1998;254(1–2):189.

Ebranhimi GR, Zarei-hanzaki A, Haghshenas M, Arashahi H. The effect of heat treatment on hot deformation behaviour of Al 2024. J Mater Process Technol. 2008;206(1–3):25.

Cavaliere P. Hot and warm forming of 2618 aluminium alloy. J Light Met. 2002;2(4):247.

Yang SL, Shen J, Zhang YA, Li ZH, Li XW, Huang SH, Xiong BQ. Processing maps and microstructural evolution of Al–Cu–Li alloy during hot deformation. Rare Met. 2018;38(12):1136.

Yan LM, Shen J, Li JP, Mao BP. Static softening behaviors of 7055 alloy during the interval time of multi-pass hot compression. Rare Met. 2013;32(3):241.

Totik Y, Gavgali M. The effect of homogenization treatment on the hot workability between the surface and the center of AA 2014 ingots. Mater Charact. 2002;49(3):261.

Liu SD, You JH, Zhang XM, Deng YL, Yuan YB. Influence of cooling rate after homogenization on the flow behavior of aluminum alloy 7050 under hot compression. Mater Sci Eng A. 2010;527(4–5):1200.

Liu C, Zhang H, Jiang FL. Characterization of dynamic microstructure evolution during hot deformation of Al–4.10Cu–1.42Mg–0.57Mn–0.12Zr alloy. Trans Nonferrous Met Soc China. 2014;24(11):3477.

Jiang FL, Zhang H, Li LX, Chen JH. The kinetics of dynamic and static softening during multistage hot deformation of 7150 aluminum alloy. Mater Sci Eng A. 2012;552:269.

Zhang J, Chen BQ, Zhang BX. Effect of initial microstructure on the hot compression deformation behavior of a 2219 aluminum alloy. Mater Des. 2012;34:15.

Verlinden B, Suhadi A, Delaey L. A generalized constitutive equation for an AA6060 aluminium alloy. Scripta Metal Et Mater. 1993;28(11):1441.

Jiang FL, Zhang H, Weng SC, Fu DF. Characterization of dynamic microstructural evolution of AA7150 aluminum alloy at high strain rate during hot deformation. Trans Nonferrous Met Soc China. 2016;26(1):51.

Zurob HS, Hutchinson CR, Brechen Y, Purdy G. Modeling recrystallization of microalloyed austenite: effect of coupling recovery, precipitation and recrystallization. Acta Mater. 2002;50(12):3077.

Humphereys FJ, Hatherly M. Recrystallization and Related Annealing Phenomena. Oxford: Pergamon Press; 1996. 557.

Tabatabaei N, Taheri AK, Vaseghi M. Dynamic strain aging of a commercial Al–Mg–Si–Cu alloy during equal channel angular extrusion process. J Alloys Compd. 2010;502(1):59.

Sha G, Wang YB, Liao XZ, Duan ZC, Ringer SP, Langdon TG. Influence of equal-channel angular pressing on precipitation in an Al–Zn–Mg–Cu alloy. Acta Mater. 2009;57(10):3123.

Cerri E, Evangelista E, Forcellese A, Mcqueen HJ. Comparative hot workability of 7012 and 7075 alloys after different pretreatments. Mater Sci Eng, A. 1995;197(2):181.

Ebrahimi GR, Ezatpour HR. Effect of precipitation on the warm deformation behavior of AA2024 alloy. Mater Sci Eng, A. 2017;681(2):10.

Bardi F, Cabibbo M, Spigarelli S. An analysis of thermo-mechanical treatments of a 2618 aluminium alloy: study of optimum conditions for warm forging. Mater Sci Eng, A. 2002;334(1–2):87.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51674111 and 51605234) and the Research Fund for the Doctoral Program of Higher Education of China (No. 20130161110007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bo, GW., Wang, G., Jiang, FL. et al. Dynamic softening and microstructural evolution during hot deformation of Al–Cu–Mg–Zr alloys with different homogenization cooling rates. Rare Met. 40, 626–634 (2021). https://doi.org/10.1007/s12598-020-01382-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01382-9