Abstract

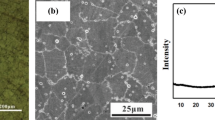

In this study, effects of B addition on the sintering densification, microstructure, hardness, friction and wear properties of sintered Fe-2.4C-4Cr-1Mo-0.5P-0.7Si-2.5Cu (in wt%) were investigated. In spite of the decreased sintered density, the addition of B changes the phase composition of the materials and their ratio. Moreover, hardness of either the matrix or the liquid solidification structure dramatically increases. These changes in microstructure result in higher friction coefficient and lower wear loss. It is observed that the addition of 0.1 wt%B offers the optimum friction and wear properties with a running-in period of only 30 s and wear volume loss of 0.006 mm3 under the testing conditions. Such friction and wear properties are superior to those of the other two widely used cam materials, cast iron and 45 steel.

Similar content being viewed by others

References

Bayrakceken H, Ucun I, Tasgetiren S. Fracture analysis of a camshaft made from nodular cast iron. Eng Fail Anal. 2006;13(8):1240.

Dobrenizki L, Tremmel S, Wartzack S, Hoffmann DC, Brögelmann T, Bobzin K, Bagcivan N, Musayev Y, Hosenfeldt T. Efficiency improvement in automobile bucket tappet/camshaft contacts by DLC coatings-influence of engine oil, temperature and camshaft speed. Surf Coat Technol. 2016;31(12):360.

Wang YM. Simulation analysis of knurling connection progress and technological parameters for assembled camshaft. Changchun: Jilin University; 2015. 2.

Lin DY, Hou BJ, Lan CC. A balancing cam mechanism for minimizing the torque fluctuation of engine camshafts. Mech Mach Theory. 2016;95(9):160.

Liu KM, Zhang YL, Kang LP, Chen ZB, Wei SY, Zou J, Hu Q. Present situation and progress of cast iron camshaft. Jiangxi Sci. 2011;29(5):616.

Scherzer R, Silbermann CB, Landgraf R, Ihlemann J. FE-simulation of the Presta joining process for assembled camshafts–modelling of the joining process. IOP Conf Ser Mater Sci Eng. 2017;181(1):1.

Wang B, Zhou LM, Mao SN. Key technology of engine camshaft manufacturing. Automob Sci Technol. 2017;1(1):60.

Song RH, Zhao BG, Liu M, Kong DJ. High temperature wear properties of FeCrBSi alloy coating by high velocity oxygen fuel. Chin J Rare Met. 2016;40(8):763.

Karamis MB, Yildizli K. Surface modification of nodular cast iron: a comparative study on graphite elimination. Mater Sci Eng A. 2010;527(20):5225.

Shen BL, Li L, Zhang H. Effect of carbon content on bending deformation and porosity of TU5JP4 chilled grey cast iron camshaft. China Foundry Mach Technol. 2012;46(6):7.

Shen BL, Gao J, Wang YR, Li L, Yue CL, Gao ZW, Yang Q, Fu ZX, Zeng Y, Shen XH. Influence of QPQ composite salt bath treating on wear resistance of alloyed gray iron for camshaft. Modern Cast Iron. 2008;28(3):74.

Xu XL, Yu ZW, Guo XY. Wear failure of truck diesel engine tappets. Eng Fail Anal. 2011;18(3):1134.

Ding YX. Research on laser surface hardening experiment for austenite-bainite nodular-iron camshaft of diesel locomotive. Hot Work Technol. 2007;36(22):76.

Li YY, Liu YB, Cao ZY. Effect of Cr content on tribological behavior of P/M cam materials. Heat Treat Met. 2007;32(8):44.

Liang XB, Li G, Wang LS, Qi HM, Wang LM, Wang L, Fang Z. Study on friction and wear properties of powder metallurgy sinter hardening cam material. Powder Metall Technol. 2015;33(2):83.

Su BW. Influence of phosphorous and boron on the tribological properties of PM iron-based sintered materials. Hefei: Hefei University of Technology; 2013. 21.

Jia J, Lu ZY, Liu WC. A study on the surface alloying for the camshaft of steel 45. J Shanxi Univ. 1999;22(1):26.

Yao ZJ, Liu WJ, Kong GP. Industrialization research of laser strengthening for air-cooled diesel engine 45# steel cam shaft. Diesel Engine. 2001;22(5):34.

Zou CS, Zhang WG, Wang L, Song HY. Research on cam & tappet friction and wear test method. Lubr Oil. 2013;28(5):41.

Sanmiguel RE, Hidalgo MM. Cam mechanisms based on a double roller translating follower of negative radius. Mech Mach Theory. 2016;95(10):93.

Bayrakceken H, Ucun I, Tasgetiren S. Fracture analysis of a camshaft made from nodular cast iron. Eng Fail Anal. 2006;13(8):1240.

Shi XL. A research on shape control of hard phases and properties improvement for a Fe-Cr-B-C system high boron iron based alloy. Kunming: Kunming University of Science and Technology; 2016. 20.

Wan BC. Effect of copper on phosphorus, boron iron-based powder metallurgy friction and wear performance. Hefei: Hefei University of Technology; 2014. 35.

Hu D. Role of boron in TiAl alloy development: a review. Rare Met. 2016;35(1):1.

Wen JK, Chen BW, Shang H, Zhang GC. Research progress in biohydrometallurgy of rare metals and heavy nonferrous metals with an emphasis on China. Rare Met. 2016;35(6):433.

Zhao W, Liu Y, Li J, Wang RQ, Qiu YC. Microstructure and magnetic properties of hot-deformed anisotropic Nd–Fe–B magnets prepared from amorphous precursors with different crystallization proportions. Rare Met. 2017;36(4):268.

Wang YP, Jia CC, Qu XH. The characteristics and the research status of powder metallurgy camshafts. Powder Metall Technol. 2011;29(4):300.

Yi DQ, Huang L, Li J, Jiang YY, Peng ZW. Sliding friction properties of WC-Ni/SiC friction couple. J Central South Univ (Sci Technol). 2009;40(1):99.

Wei J, Cui GJ. Friction and wear behavior of Fe–Cr–B alloys in liquid paraffin oil. J Tribol. 2014;137(3):223.

Dong WL. Temperature measurement of sliding friction pairs and analysis of scuffing. Chongqing: Chongqing University; 1999. 40.

Jin ZM, Shao HS. The study on formation process of three kinds of the typical abrasive debris. J Solid Lubr. 1991;11(03):151.

Zhang P. Wear properties of gray cast iron processed by laser bionic coupling technique after thermal fatigue. Changchun: Jilin University; 2014. 60.

Cheng WC, Cao XJ, Zhou D. Measurement of improving hardness and wear-ability of cam. Mater Heat Treat. 2008;37(2):95.

He J. Study on wear resistance of austenitic-bainitic ductile iron. Chongqing: Chongqing University; 2005. 70.

George S, Balla S, Gautam M. Effect of diesel soot contaminated oil on engine wear. Tribol Int. 2007;262(9):1113.

Acknowledgements

This study was financially supported by the National High-tech R&D Program (No. 2013AA031101), the Major Science and Technology Projects (No. 2012ZX04009011) and the Technology Project of Huairou District in Beijing (No. 2017-8).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, R., Wang, LS., Liang, XB. et al. Friction and wear properties of PM cam materials with different boron contents. Rare Met. 42, 4255–4263 (2023). https://doi.org/10.1007/s12598-018-1127-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1127-6