Abstract

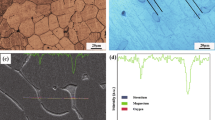

As degradable biomaterials, the higher degradation rate of Mg–Li alloys in the physiological environment is the main challenge for the implant applications. In order to try and overcome this limitation, the present work was dedicated to studying the corrosion behavior of a novel Mg–13Li–X alloy fabricated by a rapid solidification process (RSP). The special Mg–13Li–X alloy was immersed in Hank’s balanced salt solution (HBSS), and the influence of immersion time on corrosion rate was analyzed. X-ray diffraction (XRD) and scanning electron microscopy (SEM), complemented with electrochemical techniques such as potentiodynamic polarization curves and electrochemical impedance spectroscopy, were applied. Microstructural characterization indicates that the mean grain sizes of RSP Mg–13Li–X alloy are 4.2, 8.2 and 12.7 μm with the solidification rate decreasing. By contrast, the conventional as-cast Mg–13Li–X alloy has an average grain size of about 150 μm. The results of electrochemical test indicate that the sample with 4.2 μm in grain size has the most positive corrosion potential (E corr) of −1.354 V and the minimum corrosion current (I corr) of 5.830 × 10−7 A·cm−2 after immersion for 2 h in HBSS. Therefore, the finest grain size can improve the polarization resistance of the alloy, reduce its corrosion current density and increase its corrosion resistance. However, because the weak layer of the corrosion product which consists of Mg(OH)2 does not afford strong protection, the corrosion resistance becomes worse after immersion for longer periods.

Similar content being viewed by others

References

Plummer JD, Figueroa IA, Todd I. Phase stability, microstructure and mechanical properties of Li containing Mg-based bulk metallic glass composites. Mater Sci Eng A. 2012;546(6):103.

Gao P, Xue Z, Liu G, Zhang J, Zhang M. Effects of Zn on the glass forming ability and mechanical properties of MgLi-based bulk metallic glasses. Non-Cryst Solids. 2012;358(1):8.

Wu CS, Zhang Z, Cao FH, Zhang LJ, Zhang JQ, Cao CN. Study on the anodizing of AZ31 magnesium alloys in alkaline borate solutions. Appl Surf Sci. 2007;253(8):3893.

Witte F, Fischer J, Nellesen J, Crostack H, Kaese V, Pisch A, Beckmann F, Windhagen H. In vitro and in vivo corrosion measurements of magnesium alloys. Biomaterials. 2006;27(7):1013.

Nagels J, Stokdijk ML, Rozing PM. Stress shielding and bone resorption in shoulder arthroplasty. J Shoulder Elb Surg. 2003;12(1):35.

Liu D, Wu B, Wang X, Chen M. Corrosion and wear behavior of an Mg–2Zn–0.2Mn alloy in simulated body fluid. Rare Met. 2015;34(8):553.

Xu L, Yu G, Zhang E, Pan F, Yang K. In vivo corrosion behavior of Mg–Mn–Zn alloy for bone implant application. J Biomed Mater Res A. 2007;83A(3):703.

Chang T, Wang J, Chu C, Lee S. Mechanical properties and microstructures of various Mg–Li alloys. Mater Lett. 2006;60(27):3272.

Chusid O, Gofer Y, Gizbar H, Vestfrid Y, Levi E, Aurbach D, Riech I. Solid-state rechargeable magnesium batteries. Adv Mater. 2003;15(78):627.

Luo S, Zhang Q, Zhang Y, Chao L, Xu X, Zhou T. In vitro and in vivo studies on a Mg–Li–X alloy system developed as a new kind of biological metal. Mater Sci Forum. 2012;747(18):257.

Ballerini G, Bardi U, Bignucolo R, Ceraolo G. About some corrosion mechanisms of AZ91D magnesium alloy. Corros Sci. 2005;47(9):2173.

Verdier S, van der Laak N, Delalande S, Metson J, Dalard F. The surface reactivity of a magnesium-aluminium alloy in acidic fluoride solutions studied by electrochemical techniques and XPS. Appl Surf Sci. 2004;235(4):513.

Yamasaki M, Hayashi N, Izumi S, Kawamura Y. Corrosion behavior of rapidly solidified Mg–Zn-rare earth element alloys in NaCl solution. Corros Sci. 2007;49(1):255.

Liang J, Hu L, Hao J. Characterization of microarc oxidation coatings formed on AM60B magnesium alloy in silicate and phosphate electrolytes. Appl Surf Sci. 2007;253(10):4490.

Yamauchi N, Ueda N, Okamoto A, Sone T, Tsujikawa M, Oki S. DLC coating on Mg–Li alloy. Surf Coat Technol. 2007;201(9–11):4913.

Zeng R, Sun L, Zheng Y, Cui H, Han E. Corrosion and characterization of dual phase Mg–Li–Ca alloy in Hank’s solution: the influence of microstructural features. Corros Sci. 2014;79:69.

Song G, Atrens A, Dargusch M. Influence of microstructure on the corrosion of diecast AZ80D. Corros Sci. 1999;41(18):249.

Li Y, Zhang T, Wang F. Effect of microcrystallization on corrosion resistance of AZ91D alloy. Electrochim Acta. 2006;51(14):2845.

Makar GL. Corrosion studies of rapidly solidified magnesium alloys. J Electrochem Soc. 1990;137(2):414.

Zhao Y, Zhao X. Structural relaxation and its influence on the elastic properties and notch toughness of Mg–Zn–Ca bulk metallic glass. J Alloys Compd. 2012;515(15):154.

Huan ZG, Leeflang MA, Zhou J, Fratila-Apachitei LE, Duszczyk J. In vitro degradation behavior and cytocompatibility of Mg–Zn–Zr alloys. J Mater Sci Mater Med. 2010;21(9):2623.

Jiang B, Zeng Y, Yin H, Li R, Pan F. Effect of Sr on microstructure and aging behavior of Mg–14Li alloys. Prog Nat Sci Mater Int. 2012;22(2):160.

Wu L, Cui C, Wu R, Li J, Zhan H, Zhang M. Effects of Ce-rich RE additions and heat treatment on the microstructure and tensile properties of Mg–Li–Al–Zn-based alloy. Mater Sci Eng A. 2011;528(4–5):2174.

Zhang Y, Luo S, Zhang Q. Microstructures and mechanical properties of a new biomedical material Mg–13Li–X alloys. Mater Sci Forum. 2013;747:251.

Zhang C, Huang X, Zhang M, Gao L, Wu R. Electrochemical characterization of the corrosion of a Mg–Li alloy. Mater Lett. 2008;62(14):2177.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 81270116).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, BL., Chen, B., Wang, CW. et al. Corrosion behavior of a novel Mg–13Li–X alloy with different grain sizes by rapid solidification rate. Rare Met. 41, 3197–3204 (2022). https://doi.org/10.1007/s12598-015-0601-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0601-7