Abstract

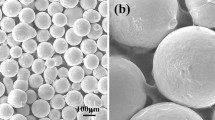

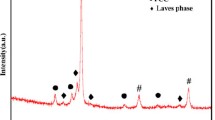

High-entropy alloy layer up to 150 μm in thickness was formed on H13 substrate with a metallurgical bonding at the coating/substrate interface. Simple solid solution phases were formed in the coating layer with a typical microstructure composed of both dendrite and interdendrite. The microstructure at the top of the cladding zone consists of equiaxed grains while that at the bottom consists of columnar grains. The coating layer exhibits great enhancement in microhardness and wear resistance compared with the H13 substrate.

Similar content being viewed by others

References

Yeh JW, Chen YL, Lin SJ, Chen SK. High-entropy alloys-a new era of exploitation. Mater Sci Forum. 2007;560:1.

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6(5):299.

Zhou YJ, Zhang Y, Kim TN, Chen GL. Microstructure characterizations and strengthening mechanism of multi-principal component AlCoCrFeNiTi0.5 solid solution alloy with excellent mechanical properties. Mater Lett. 2008;62(17–18):2673.

Chen YY, Duval T, Hung UD, Yeh JW, Shih HC. Microstructure and electrochemical properties of high entropy alloys—a comparison with type-304 stainless steel. Corros Sci. 2005;47(9):2257.

Wu JM, Lin SJ, Yeh JW, Chen SK, Huang YS, Chen HC. Adhesive wear behavior of Al x CoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear. 2006;261(5–6):513.

Zhao HB, Tu HL, Wei F, Zhang XQ, Xiong YH, Du J. Resistive switching characteristics of Dy2O3 film with a Pt nanocrystal embedding layer formed by pulsed laser deposition. Rare Met. 2014;33(1):75.

Yang S, Chen N, Liu WJ, Zhong ML. In situ formation of MoSi2/SiC composite coating on pure Al by laser cladding. Mater Lett. 2003;57(22–23):3412.

Yue TM, Li T, Lin X. Microstructure and phase evolution in laser cladding of Ni/Cu/Al multilayer on magnesium substrate. Metall Mater Trans A. 2010;41(1):212.

Yun CL, Zhang QL, Luo XF, Zhang ZR. Formation and strain distribution of Ni/NiO core/shell magnetic nanoparticles fabricated by pulser laser deposition. Sci China Phys Mech Astron. 2011;54(7):1254.

Tong CJ, Chen YL, Chen SK, Yeh JW, Shun TT, Tsau CH, Lin SJ, Chang SY. Microstructure characterization of Al x CoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall Mater Trans A. 2004;36(4):881.

Ren B, Liu ZX, Li DM, Shi L, Cai B, Wang MX. Effect of elemental interaction on microstructure of CuCrFeNiMn high entropy alloy system. J Alloy Compd. 2010;493(1–2):148.

Tung CC, Yeh JW, Shun TT, Chen SK, Huang YS, Chen HC. On the elemental effect of AlCoCrCuFeNi high-entropy alloy system. Mater Lett. 2007;61(1):1.

Wu XF, Zhang GG, Wu FF. Microstructure and dry sliding wear behavior of cast Al–Mg2Si in situ metal matrix composite modified by Nd. Rare Met. 2013;32(3):284.

Wu JM, Lin SJ, Yeh JW, Chen SK, Huang YS, Chen HC. Adhesive wear behavior of Al x CoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear. 2006;261(5–6):513.

Zhu JM, Fu HM, Zhang HF, Wang AM, Li H, Hu ZQ. Microstructure and compressive properties of multiprincipal component AlCoCrFeNiC x alloys. J Alloy Compd. 2011;509(8):3476.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 50401006), the Fundamental Research Funds for the Central Universities (No. N120409003) and the University Students’ Innovation Plan of China (No. 130066).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, XT., Lei, WB., Li, J. et al. Laser cladding of high-entropy alloy on H13 steel. Rare Met. 33, 727–730 (2014). https://doi.org/10.1007/s12598-014-0403-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0403-3