Abstract

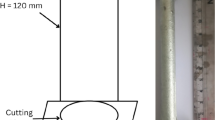

Phases and microstructures of three high Zn-containing Al–Zn–Mg–Cu alloys were investigated by means of thermodynamic calculation method, optical microscopy (OM), scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), X-ray diffraction (XRD), and differential scanning calorimetry (DSC) analysis. The results indicate that similar dendritic network morphologies are found in these three Al–Zn–Mg–Cu alloys. The as-cast 7056 aluminum alloy consists of aluminum solid solution, coarse Al/Mg(Cu, Zn, Al)2 eutectic phases, and fine intermetallic compounds η(MgZn2). Both of as-cast 7095 and 7136 aluminum alloys involve α(Al), eutectic Al/Mg(Cu, Zn, Al)2, intermetallic η(MgZn2), and θ(Al2Cu). During homogenization at 450 °C, fine η(MgZn2) can dissolve into matrix absolutely. After homogenization at 450 °C for 24 h, Mg(Cu, Zn, Al)2 phase in 7136 alloy transforms into S(Al2CuMg) while no change is found in 7056 and 7095 alloys. The thermodynamic calculation can be used to predict the phases in high Zn-containing Al–Zn–Mg–Cu alloys.

Similar content being viewed by others

References

Warner TJ, Shahani RA, Lassince P, Raynaud GM, Aluminium alloy developments for affordable airframe structures, 3rd ASM Conference on Synthesis, Processing and Modelling of Advanced Materials, Paris: 1997, 77.

Zou L, Pan QL, He Y, Wang CZ, Liang WJ. Effect of minor Sc and Zr addition on microstructures and mechanical properties of Al-Zn-Mg-Cu alloys. Trans Nonferrous Metals Soc China. 2007;17(2):340.

Dorward RC, Beerntsen DJ. Grain structure and quench-rate effects on strength and toughness of AA7050 Al–Zn–Mg–Cu–Zr alloy plate. Metall Mater Trans A. 1995;26(9):2481.

Srivatsan TS, Sriram S, Veeraraghavan D, Vasudevan VK. Microstructure, tensile deformation and fracture behaviour of aluminium alloy 7055. J Mater Sci. 1997;32(11):2883.

AMS 4407. Aluminum alloy, plate (7056-T7651) 9.1Zn–1.6Cu–1.9Mg solution heat treated, stress relieved, and overaged. SAE international, 2007.

Benedictus R, Keidel, C J, Heinz A L. High-strength, high toughness Al-Zn alloy product and method for producing such product. US patent, 2006/0174980 A1, 2006.

Voreppe T W, Grenoble C S, Seyssins B B. Al–Zn–Mg-Cu alloys and products with improved ratio of static mechanical characteristics to damage tolerance. US patent, 2003/0219353 A1, 2003.

Yan LM, Shen J, Li JP, Mao BP. Static softening behaviors of 7055 alloy during the interval time of multi-pass hot compression. Rare Met. 2013;32(3):241.

Li XM, Starink MJ. Effect of compositional variations on characteristics of coarse intermetallic particles in overaged 7000 aluminium alloys. Mater Sci Technol. 2001;17(11):1324.

Godard D, Archambault P, Aeby-Gautier E, Lapasset G. Precipitation sequences during quenching of the AA 7010 alloy. Acta Mater. 2002;50(9):2319.

Mondal C, Mukhopadhyay AK. On the nature of T(Al2Mg3Zn3) and S(Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy. Mater Sci Eng A. 2005;391(1):367.

Rokhlin LL, Dobatkina TV, Bochvar NR, Lysova EV. Investigation of phase equilibria in alloys of the Al–Zn–Mg–Cu–Zr–Sc system. J Alloy Compd. 2004;367(1):10.

He LZ, Li XH, Zhu P, Cao YH, Guo YP, Cui JZ. Effects of high magnetic field on the evolutions of constituent phases in 7085 aluminum alloy during homogenization. Mater Charact. 2012;71:19.

Mondolfo LF. Aluminum Alloys: Structure and Properties. London: Butterworths; 1976. 842.

Fan X, Jiang D, Meng Q, Zhong L. The microstructural evolution of an Al–Zn–Mg–Cu alloy during homogenization. Mater Lett. 2006;60(12):1475.

Xie FY, Yan XY, Ding L, Zhang F, Chen SL, Chu MG, Chang YA. A study of microstructure and microsegregation of aluminum 7050 alloy. Mater Sci Eng A. 2003;355(1–2):144.

Fan XG, Jiang DM, Meng QC, Zhang BY, Wang T. Evolution of eutectic structures in Al–Zn–Mg–Cu alloys during heat treatment. Trans Nonferrous Metals Soc China. 2006;16(3):577.

Lim ST, Eun IS, Nam SW. Control of equilibrium phases (M, T, S) in the modified aluminum alloy 7175 for thick forging applications. Mater Trans. 2003;44(1):181.

Deng YL, Wan L, Wu LH, Zhang YY, Zhang XM. Microstructural evolution of Al–Zn–Mg–Cu alloy during homogenization. J Mater Sci. 2011;46(4):875.

Robson JD. Microstructural evolution in aluminium alloy 7050 during processing. Mater Sci Eng, A. 2004;382(1):112.

Acknowledgments

This study was financially supported by the National Program on Key Basic Research Project of China (No. 2012CB619504), National Natural Science Foundation of China (No. 51271037), and the International Scientific and Technological Cooperation Projects (No. 2010DFB50340)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, JT., Zhang, YA., Li, XW. et al. Phases and microstructures of high Zn-containing Al–Zn–Mg–Cu alloys. Rare Met. 35, 380–384 (2016). https://doi.org/10.1007/s12598-014-0222-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0222-6