Abstract

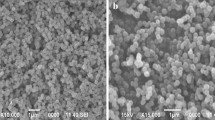

Al2O3-metal composite coatings with different reactants and diluents were fabricated on mild steel plate with nonpressure combustion synthesis process. The coatings were characterized by means of X-ray diffraction, scanning electron microscopy, and energy-dispersive spectrometry, respectively. Thermal shock tests were carried out to determine the bond strength of the coating with the steel substrate. The results indicate that the coating is composed of α-Al2O3, α-(Fe–Cr) and Al2SiO5 as the main phases. It is found that the coating with the diluents of Al2O3–SiO2 and transition layer of Al2O3–Cr presents the highest hardness of 2270 HV0.2 and the lowest porosity of 3.93 %. Owing to a metallurgical bond of the coating-to-substrate, the coating exhibits a good thermal shock resistance.

Similar content being viewed by others

References

Masanta M, Shariff SM, Choudhury AR. Tribological behavior of TiB2–TiC–Al2O3 composite coating synthesized by combined SHS and laser technology. Surf Coat Technol. 2010;204(16–17):2527.

Masanta M, Ganesh P, Kaul R, Nath AK, Choudhury AR. Development of a hard nano-structured multi-component ceramic coating by laser cladding. Mater Sci Eng A. 2009;508(1–2):134.

Yang Y, Yan DR, Dong YC, Wang L, Chen XG, Zhang JX. In-situ nanostructured ceramic matrix composite coating prepared by reactive plasma spraying micro-sized Al–Fe2O3 composite powders. J Alloy Compd. 2011;509(5):L90.

Zhang JJ, Wang ZH, Lin PH, Yuan HB, Zhou ZH, Jiang SQ. Effect of sealing treatment on corrosion resistance of plasma-sprayed NiCrAl/Cr2O3-8 wt%TiO2 coating. J Therm Spray Technol. 2011;20(3):508.

Li ZW, Liu CS, Huang JH, Yin S. Synthesis and deposition of TiC–Fe coatings by oxygen-acetylene flame spraying. J Mater Sci Technol. 2003;19(2):161.

Cheng JB, Wang ZH, Xu BS. Wear and corrosion behaviors of FeCrBSiNbW amorphous/nanocrystalline coating prepared by arc spraying process. J Therm Spray Technol. 2012;21(5):1025.

Borchers C, Gärtner F, Stoltenhoff T, Kreye H. Formation of persistent dislocation loops by ultra-high strain-rate deformation during cold spraying. Acta Mater. 2005;53(10):2991.

Roos E, Naga SM, Richter RN, Lauf S, Awaad M, Lyutovich A, Tameem MA. Electron beam physical vapour deposition and mechanical properties of c-ZrO2-ZTA-coatings on alloy 617 substrates. Ceram Int. 2012;38(4):3317.

Li JS, Zhang CR, Li B, Gao F, Wang SQ. Boron nitride coatings by chemical vapor deposition from borazine. Surf Coat Technol. 2011;205(12):3736.

Tiwari SK, Sahu RK, Pramanick AK, Singh R. Development of conversion coating on mild steel prior to sol gel nanostructured Al2O3 coating for enhancement of corrosion resistance. Surf Coat Technol. 2011;205(21–22):4960.

Xie GZ, Song XL, Zhang DJ, Wu YP, Lin PH. Microstructure and corrosion properties of thick WC composite coating formed by plasma cladding. Appl Surf Sci. 2010;256(21):6354.

Li J, Yu ZS, Wang HP, Li MP. Microstructural characterization of titanium matrix composite coatings reinforced by in situ synthesized TiB+TiC fabricated on Ti6Al4V by laser cladding. Rare Met. 2010;29(5):465.

La PQ, Bai MW, Xue QJ, Liu WM. A study of Ni3Al coating on carbon steel surface via the SHS casting route. Surf Coat Technol. 1999;113(1–2):44.

Merzhanov AG. The chemistry of self-propagating high-temperature synthesis. J Mater Chem. 2004;14(12):1779.

Niu MY, Bi QL, Kong LQ, Yang J, Liu WM. A study of Ni3Si-based composite coating fabricated by self-propagating high temperature synthesis casting route. Surf Coat Technol. 2011;205(15):4249.

La PQ, Xue QJ, Liu WM. A study of MoSi2–MoS2 coatings fabricated by SHS casting route. Mater Sci Eng A. 2000;277(1–2):266.

Rosa R, Veronesi P, Poli G, Leonelli C, Corradi AB, Casagrande A, Boromei I. Ni–Al–Ti coatings obtained by microwave assisted combustion synthesis. Surf Eng. 2012;28(2):91.

Motlagh EB, Nasiri H, Khaki JV, Sabzevar MH. Formation of metal matrix composite reinforced with nano sized Al2O3+Ni–Al intermetallics during coating of Al substrate via combustion synthesis. Surf Coat Technol. 2011;205(23–24):5515.

Yan YW, Fu ZY, Yuan RZ. In-situ synthesis and characteristics of TiC–Fe cermet graded composite coating on a steel substrate. J Wuhan Univ Technol Mater Sci Ed. 2003;18(4):14.

Chatterjee S, Shariff SM, Padmanabham G, Majumdar JD, Choudhury AR. Study on the effect of laser post-treatment on the properties of nanostructured Al2O3–TiB2–TiN based coatings developed by combined SHS and laser surface alloying. Surf Coat Technol. 2010;205(1):131.

Massalski TB, Okamoto H, Subramanian PR, Kacprzak L. Binary alloy phase diagrams. 2nd ed. Ohio: Materials Park, ASM International; 1990. 1273.

Wu QL, Li WG. The microstructure and wear properties of laser-clad WC-Cr3C2 cermet coating on steel substrate. Mater Trans. 2011;52(3):560.

Puszynski JA, Miao SX, Stefansson B, Jagarlamudi S. In situ densification of combustion synthesized coatings. AIChE J. 1997;43(11A):2751.

Moore JJ, Feng HJ. Combustion synthesis of advanced materials: part II. Classification, applications and modelling. Prog Mater Sci. 1995;39(4–5):275.

Bhattacharya AK. Green density of a powder compact and its influence on the steady-state wave velocity in combustion synthesis of condensed phase. J Am Ceram Soc. 1991;74(9):2113.

Mossino P. Some aspects in self-propagating high-temperature synthesis. Ceram Int. 2004;30(3):311.

Du ZZ, Fu HG, Fu HF, Xiao Q. A study of ceramic-lined compound copper pipe produced by SHS–centrifugal casting. Mater Lett. 2005;59(14–15):1853.

Ali-Rachedi M, Ramdane W, Vrel D, Benaldjia A, Langlois P, Guerioune M. The role of sintering additives on synthesis of cermets by auto-combustion. Powder Technol. 2010;197(3):303.

Acknowledgments

This work was financially supported by the Ministry of Education of China (No. 625010312).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, CH., Wang, ZH., Zhou, ZH. et al. Fabrication and characterization of Al2O3-metal composite coating on steel plate with nonpressure combustion synthesis. Rare Met. 32, 390–396 (2013). https://doi.org/10.1007/s12598-013-0104-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0104-3