Abstract

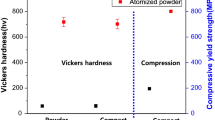

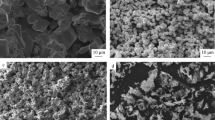

Spark plasma sintering (SPS) method was used to sinter two different types of 93W-5.6Ni-1.4Fe (wt pct) heavy alloy powders which were respectively prepared by simple mixing and high-energy ball milling (HEBM) for 40 h. In SPS processing, the powder compacts were heated at 100 °C/min to the desired sintering temperature with 5 min holding. The SPS densification behavior of the two types of powders was investigated. For the simple mixed powders, the compacts start to shrink around 850 °C, and the densification is enhanced by diffusion and plastic deformation with the increase of temperature. Consequently the compacts shrink effectively and obtain nearly full density around 1230 °C. While for the as-milled powders, recovery and recrystallization occur between 700–850 °C due to the crystal lattice distortion and defects resulted from HEBM, causing the soften of particles and a slight shrink of compacts. When increasing temperature, nanosintering of W crystallines in the matrix occurs in the inside of the composite powders, and the densification rate accelerates and maximizes at about 1050 °C. Owing to the improved activity of powders from HEBM, the tungsten grains coarsen rapidly in the sintering, simultaneously, the harmful intermetallic phases Ni2W4C and Fe6W6C are generated.

Similar content being viewed by others

References

Yu Y., Wang E.D., and Hu L.X., Effect of nanocrystalline tungsten powders on the microstructure and properties of liquid-phase sintered 93 W alloys, Mater. Sci. and Technol., 2006, 14(4): 385.

Hong S.H., and Ryu H.J., Combination of mechanical alloying and two-stage sintering of a 93W-5.6Ni-1.4Fe tungsten heavy alloy, Mater. Sci. Eng. A, 2003, 344(1–2): 253.

Zhu Y.B., Wang Y., Zhang X.Y., and Qin G.W., W-Ni-Fe phase interfacial characteristics of liquid-phase sintered W-Ni-Fe alloy, Int. J. Refract. Met. Hard Mater., 2007, 25(4): 275.

German R.M., Sintering Theory and Practice, Wiley, New York, NY, 1996. 230.

Cai W.D., Li Y. Dowding R.J., Mohamed F.A., and Lavernia E.J., A review of tungsten-based alloys as kinetic energy penetrator materials, Rev. Particul. Mater., 1995, 3: 71.

White G.D., and Gurwell W.E., Freeze dried tungsten heavy alloy, Adv. Powder. Metall., 1989, 12(1): 355.

Raghunathan S., and Bourell D.L., Synthesis and evaluation of advanced nanocrystalline tungsten-based materials, P/M Sci. Technol. Briefs, 1999, 1(1): 9.

Fan J.L., Huang B.Y., and Qu X.H., W-Ni-Fe nanostructure materials synthesized by high energy ball milling, Trans. Nonferrous Met. Soc. China, 2000, 10(1): 57.

Gurwell W.E., Solid state sintering of tungsten heavy alloys, [in] Tungsten Refract Met-1994, Proc Int. Conf, 2nd, 1995. 65.

Sylvia T.H., Thomas H., and Theador S., Talor-made tungsten heavy alloy by solid state sintering of pre-alloyed powder and subsequent add working, [in] Tungsten Refract Met-1994, Proc Int. Conf, 2nd, 1995. 169.

Ryu H.J., Hong S.H., and Baek W.H., Mechanical alloying process of 93W-5.6Ni-1.4Fe tungsten heavy alloy, J. Mater. Process. Technol., 1997, 63(1–3): 292.

Ryu H.J., and Hong S.H., Fabrication and properties of mechanically alloyed oxide-dispersed tungsten heavy alloys, Mater. Sci. Eng. A, 2003, 363(1–2): 179.

Wu G.C., You Q., and Wang D., Influence of the addition of Lanthanum on a W-Mo-Ni-Fe heavy alloy, Int. J. Refract. Met. Hard Mater., 1999, 17(4): 299.

Hong S.H., Kang S.L., Yoon D.N., and Baek W.H., Reduction of the interfacial segregation of phosphorus and its embrittlement effect by lanthanum addition in a W-Ni-Fe heavy alloy, Metall. Trans. A, 1991, 22A(12): 2969.

Park S., Kim D.K., Lee S., Ryu H.J., and Hong S.H., Dynamic deformation behavior of an oxide-dispersed tungsten heavy alloy fabricated by mechanical alloying, Metall. Mater. Trans. A, 2001, 32(8): 2011.

Lee K.H., Cha S.I., Ryu H.J., and Hong S.H., Effect of two-stage sintering process on microstructure and mechanical properties of ODS tungsten heavy alloy, Mater. Sci. Eng. A, 2007, 458(1–2): 323.

Upadhyaya A., Tiwari S.K., and Mishra P., Microwave sintering of W-Ni-Fe alloy, Scr. Mater., 2007, 56(1): 5.

Prabhu G., Chakraborty A., and Sarma B., Microwave sintering of tungsten, Int. J. Refract. Met. Hard Mater., 2009, 27(3): 545.

Li X.Q., Xin H.W., Hu K., and Li Y.Y, Microstructure and properties of ultra-fine tungsten heavy alloys prepared by mechanical alloying and electric current activated sintering, Trans. Nonferrous Met. Soc. China, 2010, 20(3): 443.

Li Y.Y., Li, X.Q., Long Y., Xia W., Zhu M., and Chen W.P., Fabrication of iron-base alloy by spark plasma sintering, J. Mater. Sci. Technol., 2006, 22(2): 257.

Vanmeensel K., Laptev A., Hennicke J., Vleugels J., and VanderBiest O., Modelling of the temperature distribution during field assisted sintering, Acta Mater., 2005, 53(16): 4379.

Kim J.C., and Moon I.H., Sintering of nanosturcutured W-Cu alloys prepared by mechanical alloying, Nanostr. Mater., 1998, 10(2): 283.

Ryu S.S., Kim Y.D., and Moon I.H., Dilatometric analysis on the sintering behavior of nanocrystalline W-Cu prepared by mechanical alloying, J. Alloy. Compd., 2002, 335: 233.

Song X.Y., Liu X.M., and Zhang J.X, Neck formation and self-adjusting mechanism of neck growth of conducting powders in spark plasma sintering, J. Am. Ceram. Soc., 2006, 89(2): 494.

Dore F., Martin C.L., and Allibert C.H., Apparent viscosity of W-Cu powder compacts during sintering, Mater. Sci. Eng. A, 2004, 383(2): 390.

Fan J.L., Huang B.Y., Qu X.H., and Zou Z.Q, Thermal stability, grain growth and structure changes of mechanically alloyed W-Ni-Fe composite during annealing, Int. J. Refract. Met. Hard Mater., 2001, 19(2): 73.

Akhtar F., An investigation on the solid states sintering of mechanically alloyed nano-structured 90W-Ni-Fe tungsten heavy alloy, Int. J. Refract. Met. Hard Mater., 2008, 26(3): 145.

Ryu H.J., Hong S.H., and Baek W.H., Microstructure and mechanical properties of mechanically alloyed and solid-state sintered tungsten heavy alloys, Mater. Sci. Eng. A, 2000, 291(1–2): 91.

Maneshian M.H., and Simchi A., Solid state and liquid phase sintering of mechanically activated W-20 wt.%Cu powder mixture, J. Alloy. Compd., 2008, 463(1–2): 153.

Suryanarayana C., Mechanical alloying and milling, Prog. Mater. Sci., 2001, 46(1–2): 1.

Zhang D.L., Processing of advanced materials using high-energy mechanical milling, Prog. Mater. Sci., 2004, 49: 537.

Kim J.C., Ryu S.S., Kim Y.D., and Moon I.H., Densification behavior of mechanically alloyed W-Cu composite powders by the double rearrangement process, Scr. Mater., 1998, 39(6): 669.

Hong S.H., Kim B.K., and Munir Z.A., Synthesis and consolidation of nanostructured W-10-40 wt.%Cu powders, Mater. Sci. Eng. A, 2005, 405(1–2): 325.

Groza J.R., Nanosintering, Nanostr. Mater., 1999, 12(5–8): 987.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, K., Li, X., Zheng, D. et al. SPS densification behavior of W-5.6Ni-1.4Fe heavy alloy powders. Rare Metals 30 (Suppl 1), 581–587 (2011). https://doi.org/10.1007/s12598-011-0351-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-011-0351-z