Abstract

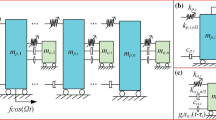

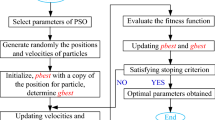

It is a limitation for rapid development of microelectronics manufacturing industry to hardly overcome the acceleration limitation of macro–micro motion platform. The paper presents an extended ultra-high acceleration macro–micro motion platform to investigate breakthrough of acceleration limitation with driving modes “macro + micro + macro” (MMM). In the proposed platform, the number of the pair of VCMs was defined as n. Under ultra-high acceleration, floating stator stage is suggested to isolate the vibration and obtain superior performance of the platform. Its theoretical analyses including natural frequency analysis, transient response analysis and frequency response analysis are performed to verify vibration isolation of floating stator stage applied in the extended ultra-high acceleration macro–micro motion platform. The change trends and sensitivities of related objective functions incorporating vibration transmissibility, settling time and the maximum stroke of stator’s motion are explored with their related parameters, and their multi-objective optimization designs are carried out to achieve superior performances of different extended platforms. Moreover, one case is performed when n = 1. Its theoretical analyses, change trends and sensitivities are investigated. The superior performance of the platform is obtained to realize vibration isolation by multi-objective optimization. And its experiment of vibration isolation is also testified finally. The results provide a theoretical and technical basis on microelectronics manufacturing equipment upgrading and manufacturing rapid development.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- α :

-

Ratio of circular frequency ω1 and ω2

- a :

-

State variable matrix

- a 1, a 2, a 3, a 4 :

-

State components

- A n :

-

System matrix in extended ultra-high acceleration macro–micro motion platform

- A n1 , A n2 :

-

Amplitude of x1 and x2 in extended of ultra-high acceleration macro–micro motion platform

- B :

-

Input matrix

- C n :

-

Damping matrix in extended ultra-high acceleration macro–micro motion platform

- C :

-

Output matrix

- c2 :

-

Equivalent damper between base and ground in extended ultra-high acceleration macro–micro motion platform

- c n0 , c n1 :

-

Equivalent damping coefficients of guide rail and slide block, damper in extended ultra-high acceleration macro–micro motion platform

- F n :

-

Force matrix in extended ultra-high acceleration macro–micro motion platform

- F n(t):

-

Equivalent impulse function

- F n0 :

-

Equivalent reactive force in extended ultra-high acceleration macro–micro motion platform

- f 1, f 2 :

-

Frequency of stator, base

- K n :

-

Stiffness matrix in extended ultra-high acceleration macro–micro motion platform

- k 2 :

-

Equivalent stiffness between base and ground

- k n1 :

-

Equivalent stiffness coefficients of spring in extended ultra-high acceleration macro–micro motion platform

- m 1, m 2 :

-

Equivalent mass of stator, base. (m1 = m)

- m n1 :

-

Equivalent mass of stator in extended ultra-high acceleration macro–micro motion platform

- M n :

-

Mass matrix in extended ultra-high acceleration macro–micro motion platform

- Pn :

-

Amplitude of reactive force in extended ultra-high acceleration macro–micro motion platform

- t :

-

Time

- ∆t :

-

Pulse length

- u :

-

Signal input matrix

- μ :

-

Ratio of mass m2 and m1

- μ n :

-

Ratio of mass m2 and m n1

- ω :

-

Circular frequency

- ω n :

-

Circular frequency in extended ultra-high acceleration macro–micro motion platform

- ω 1, ω 2 :

-

Circular frequency of stator, base

- ω n1 , ω n2 :

-

Circular frequency of stator, base in extended ultra-high acceleration macro–micro motion platform

- X :

-

Matrix of displacement

- x 1, x 2 :

-

Displacement of stator, base

- Z n(ω):

-

Frequency function in extended ultra-high acceleration macro–micro motion platform

- ζ 1, ζ 2 :

-

Damping factor of stator, base

- ζ n1 , ζ n2 :

-

Damping factor of stator, base in extended ultra-high acceleration macro–micro motion platform

- ξ :

-

Damping factor

- ξ n :

-

Damping factor in extended ultra-high acceleration macro–micro motion platform

- λ, λ n :

-

Ratio of circular frequency ω and ω1, ratio of circular frequency ω and ω n1

References

Wang, Y., Ma, H., Yang, J., & Wang, K. (2017). Industry 4.0: a way from mass customization to mass personalization production. Advances in Manufacturing, 5(4), 11–320.

Zhang, L., Gao, J., & Chen, X. (2018). A rapid dynamic positioning method for settling time reduction through a macro-micro composite stage with high positioning accuracy. IEEE Transactions on Industrial Electronics, 65(6), 4849–4853.

Deng, Y., Jin, X., & Zhang, Z. (2015). A macro-micro compensation method for straightness motion error and positioning error of an improved linear stage. International Journal of Advanced Manufacturing Technology, 80(9-12), 1799–1806.

Fang, J., Long, Z., Wang, M., Zhang, L., & Dai, X. (2016). Multi-mode sliding mode control for precision linear stage based on fixed or floating stator. Review of Scientific Instrument, 87(025115), 1–10.

Zhang, L., Li, X., Fang, J., & Long, Z. (2017). Multi-objective positioning design optimization of flexure hinge mechanism considering thermal-mechanical coupling deformation and natural frequency. Advances in Mechanical Engineering, 9(1), 1–17.

Fang, J., Zhang, L., Long, Z., & Wang, M. (2018). Fuzzy adaptive sliding mode control for the precision position of piezo-actuated nano positioning stage. International Journal of Precision Engineering and Manufacturing, 19(10), 1447–1456.

Fang, J., Zhong, W., Li, C., Zhao, Z., & Wang, M. Y. (2019). Fuzzy adaptive multi-mode sliding mode control for precision linear stage based on floating stator. Review of Scientific Instruments, 90(1), 015103-1-10.

Li, Y., Marcassa, F., Horowitz, R., Oboe, R., & Evans, R. (2006). Track-following control with active vibration damping of a PZT-actuated suspension dual-stage servo system. Journal of Dynamic Systems Measurement and Control-Transactions of the ASME, 128(3), 568–576.

Li, Y., & Horowitz, R. (2002). Design and testing of track-following controllers for dual-stage servo systems with PZT actuated suspensions. Microsystem Technologies, 8(2-3), 194–205.

Liu, Y., Fung, R., & Wang, C. (2007). Application of the nonlinear, double-dynamic taguchi method to the precision positioning device using combined Piezo-VCM actuator. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 54(2), 240–250.

Liu, Y., Fung, R., & Wang, C. (2005). Precision position control using combined piezo-VCM actuators. Precision Engineering-Journal of the International Societies for Precision Engineering and Nanotechnology, 29(4), 411–422.

Sapidis, N., & Farin, G. (1990). Automatic fairing algorithm for B-spline curves. Computer-Aided Design, 22(2), 121–129.

Elfizy, A., Bone, G., & Elbestawi, M. (2005). Design and control of a dual-stage feed drive. International Journal of Machine Tools and Manufacture, 45(2), 153–165.

Tong, D., Veldhuis, S., & Elbestawi, M. (2007). Control of a dual stage magnetostrictive actuator and linear motor feed drive system. International Journal of Advanced Manufacturing Technology, 33(3-4), 379–388.

Heui, J., Dong, S., & Jong, H. (2001). Ultra-precision positioning system for servo motor-piezo actuator using the dual loop and digital filter implementation. International Journal of Machine Tool & Manufacture, 41, 51–63.

Wang, H. (2013) Research on high performance positioning stage with floating stator. PhD Thesis, Harbin Institute of Technology.

He, X. (2007). Dynamics of the ultra-precision positioning stage with gas-lubricated bearings. PhD Thesis, Huazhong University of Science and Technology.

Li, Z. (2008) Study on optimization of dynamics characteristics of an ultra-precision positioning stage with gas-lubricated bearings. PhD Thesis, Huazhong University of Science and Technology.

Quan, Z. (2007) Study on structure design and characteristic analysis of a nano-stepping piezoelectric actuator. PhD Thesis, Tianjin University.

Li, X. (2008) Study of fundament technologies for large range and high precision 2-D coarse/fine positioner. PhD Thesis, Zhejiang University.

Li, M. (2007) Research on some key techniques of long stroke nano-positioning system. PhD Thesis, Shanghai University.

Dong, W., Tang, J., & Eideeb, Y. (2008). Design of dual-stage actuation system for high precision optical manufacturing. Proceedings of SPIE, 6928, 1–7.

Ha, J., Kung, Y., Hu, S., & Fung, R. (2006). Optimal design of a micro-positioning Scott-Russell mechanism by Taguchi method. Sensors and Actuators A, 125, 565–572.

Matsubara, A., Fujita, T., Kono, D., & et al. (2007). Nano positioning drive with piezoelectric actuator integrated into support bearing unit of ball screw. In Proceedings of the 35th international MATADOR conference, Manchester, pp. 323–326.

Zhang, L., Long, Z., Cai, J., Luo, F., Fang, J., & Wang, M. (2015). Multi-objective optimization design of a connection frame in macro–micro motion platform. Applied Soft Computing, 32, 369–382.

Zhang, L., Long, Z., Fang, J., Wang, Z., & Yang, J. (2012). A linear macro-micro platform design based on FEM simulation. Advanced Materials Research, 605–607, 1379–1386.

Zhang, L., Long, Z., Nian, L., & Fang, J. (2013). Finite element analysis for connection mechanism in macro-micro platform. International Journal of Materials Science and Engineering, 1(2), 50–56.

Zhang, L., Long, Z., Cai, J., & Fang, J. (2014). Error analysis of connection frame deformation considering magnetic force and thermal-structural coupling effects. In Proceedings of the 14th IEEE international conference on nanotechnology, Toronto, pp. 925–929.

Zhang, L., Long, Z., Fang, J., & Nian, L. (2014). Light weight optimization design for a connection frame considering thermal-structural coupling deformation. In Proceedings of the ASME 2014 international mechanical engineering congress and exposition, Montreal, pp. 1–9.

Zhang, L., Long, Z., Cai, J., Liu, Y., Fang, J., & Wang, M. (2015). Active vibration isolation of macro-micro motion stage disturbances using a floated stator platform. Journal of Sound and Vibration, 354, 13–33.

Trompette, P., & Fatemi, J. (1997). Damping of beams. optimal distribution of cuts in the viscoelastic constrained layer. Structural Optimization, 13(2-3), 167–171.

Yi, Y., Park, S., & Youn, S. (2000). Design of microstructures of viscoelastic composites for optimal damping characteristics. International Journal of Solids and Structures, 37(35), 4791–4810.

Zheng, L., Xie, R., Wang, Y., & Elsabbagh, A. (2011). Topology optimization of constrained layer damping on plates using Method of Moving Asymptote (MMA) approach. Shock and Vibration, 18(1-2), 221–244.

Trelea, I. C. (2003). The particle swarm optimization algorithm: convergence analysis and parameter selection. Information Processing Letters, 85(6), 317–325.

Ning, J. Q., & Liang, S. Y. (2018). Model-driven determination of Johnson–Cook material constants using temperature and force measurements. The International Journal of Advanced Manufacturing Technology, 97(1-4), 1053–1060.

Ning, J. Q., Nguyen, V., Huang, Y., Hartwig, K. T., & Liang, S. Y. (2018). Inverse identification of Johnson-Cook material constants based on modified chip formation model and iterative gradient search using temperature and force measurements. The International Journal of Advanced Manufacturing Technology, 99(5-8), 1131–1140.

Ning, J. Q., & Liang, S. Y. (2019). Inverse identification of Johnson-Cook material constants based on modified chip formation model and iterative gradient search using temperature and force measurements. The International Journal of Advanced Manufacturing Technology. https://doi.org/10.1007/s00170-019-03286-0.

Nalbant, M., Gökkaya, H., & Sur, G. (2007). Application of Taguchi method in the optimization of cutting parameters for surface roughness in turning. Materials and Design, 28(4), 1379–1385.

Dong, W., Tang, J., & Eideeb, Y. (2009). Design of a linear-motion dual-stage actuation system for precision control. Smart Materials and Structures, 18(9), 11–18.

Wang, H., & Li, Z. (2012). Design of high performance linear stage with floating stator. Journal of Chinese Society of Mechanical Engineers, 33(6), 553–563.

Haftka, R. T., & Adelman, H. M. (1989). Recent development in structural sensitivity analysis. Structural Optimization, 1(3), 137–151.

Deb, K., Agaiwal, S., & Megarivan, T. (2002). A fast and elitist multi-objective genetic algorithm: NSGA-II. IEEE Transactions on Evolutionary Computation, 6(2), 182–197.

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant No. 51705132), the National Natural Science Foundation of China (Grant No. 51705217), the Science and Technology Department of Henan Province Natural Science Project (Grant No. 172102210215), Henan Postdoctoral Foundation, doctoral Foundation (2016BS008) and the Education Department of Henan Province Natural Science Project (Grant No. 17A460008), China Postdoctoral Science Foundation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

Terms in Eq. (2):

Appendix B

Input signal:

Appendix C

Terms in Eq. (6):

Appendix D

Rights and permissions

About this article

Cite this article

Zhang, Lf., Li, Xl., Fang, Jw. et al. Vibration Isolation of Extended Ultra-High Acceleration Macro–Micro Motion Platform Considering Floating Stator Stage. Int. J. Precis. Eng. Manuf. 20, 1265–1287 (2019). https://doi.org/10.1007/s12541-019-00152-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00152-7