Abstract

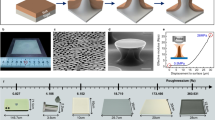

Bioinspired dry adhesives have attracted considerable attention over the last decade because of their superiority in properties, such as adhesion strength, repeatable and reversible adhesion, rough surface adaptation, self-cleaning, and directional adhesion. However, previous manufacturing techniques of bioinspired dry adhesives based on lithographic approaches, such as photolithography or ebeam lithography, require high-cost, sophisticated, and non-environmental friendly processes and materials. These requirements significantly limit the scalable production and commercialization of bioinspired dry adhesives. In this paper, we present a new manufacturing technique based on automated CNC machining and replica molding. This method enables simple and scalable fabrication of bioinspired dry adhesives. Our suggested manufacturing process will facilitate the widespread use and commercialization of biomimetic smart dry adhesives.

Similar content being viewed by others

Abbreviations

- AR:

-

aspect ratio

- CNTs:

-

carbon nanotubes

- CNC:

-

computer numerical control

- PDMS:

-

polydimethylsiloxane

- Si:

-

silicon

References

Autumn, K., Liang, Y. A., Hsieh, S. T., Zesch, W., Chan, W. P., et al., “Adhesive force of a Single Gecko Foot-Hair,” Nature, Vol. 405, No. 6787, pp. 681–685, 2000.

Federle, W., “Why Are So Many Adhesive Pads Hairy?” Journal of Experimental Biology, Vol. 209, No. 14, pp. 2611–2621, 2006.

Autumn, K., Sitti, M., Liang, Y. A., Peattie, A. M., Hansen, W. R., et al., “Evidence for Van Der Waals Adhesion in Gecko Setae,” Proceedings of the National Academy of Sciences, Vol. 99, No. 19, pp. 12252–12256, 2002.

Guo, D.-J., Liu, R., Cheng, Y., Zhang, H., Zhou, L.-M., et al., “Reverse Adhesion of a Gecko-Inspired Synthetic Adhesive Switched by an Ion-Exchange Polymer-Metal Composite Actuator,” ACS Applied Materials & Interfaces, Vol. 7, No. 9, pp. 5480–5487, 2015.

Krahn, J., Bovero, E., and Menon, C., “Magnetic Field Switchable Dry Adhesives,” ACS Applied Materials & Interfaces, Vol. 7, No. 4, pp. 2214–2222, 2015.

Yi, H., Kang, M., Kwak, M. K., and Jeong, H. E., “Simple and Reliable Fabrication of Bioinspired Mushroom-Shaped Micropillars with Precisely Controlled Tip Geometries,” ACS Applied Materials & Interfaces, Vol. 8, No. 34, pp. 22671–22678, 2016.

Im, H. S., Kwon, K. Y., Kim, J. U., Kim, K. S., Yi, H., et al., “Highly Durable and Unidirectionally Stooped Polymeric Nanohairs for Gecko-Like Dry Adhesive,” Nanotechnology, Vol. 26, No. 41, Paper No. 415301, 2015.

Arzt, E., Gorb, S., and Spolenak, R., “From Micro to Nano Contacts in Biological Attachment Devices,” Proceedings of the National Academy of Sciences, Vol. 100, No. 19, pp. 10603–10606, 2003.

Gorb, S., Varenberg, M., Peressadko, A., and Tuma, J., “Biomimetic Mushroom-Shaped Fibrillar Adhesive Microstructure,” Journal of the Royal Society Interface, Vol. 4, No. 13, pp. 271–275, 2007.

Gorb, S. N. and Varenberg, M., “Mushroom-Shaped Geometry of Contact Elements in Biological Adhesive Systems,” Journal of Adhesion Science and Technology, Vol. 21, Nos. 12-13, pp. 1175–1183, 2007.

Chen, B., Zhong, G., Goldberg Oppenheimer, P., Zhang, C., Tornatzky, H., et al., “Influence of Packing Density and Surface Roughness of Vertically-Aligned Carbon Nanotubes on Adhesive Properties of Gecko-Inspired Mimetics,” ACS Applied Materials & Interfaces, Vol. 7, No. 6, pp. 3626–3632, 2015.

del Campo, A., Greiner, C., Álvarez, I., and Arzt, E., “Patterned Surfaces with Pillars with Controlled 3D Tip Geometry Mimicking Bioattachment Devices,” Advanced Materials, Vol. 19, No. 15, pp. 1973–1977, 2007.

Kim, J. H., Kang, S. M., Lee, B. J., Ko, H., Bae, W.-G., et al., “Remote Manipulation of Droplets on a Flexible Magnetically Responsive Film,” Scientific Reports, Vol. 5, 2015. (DOI: 10.1038/srep17843)

Ko, H., Yi, H., and Jeong, H. E., “Wall and Ceiling Climbing Quadruped Robot with Superior Water Repellency Manufactured Using 3D Printing (UNIclimb),” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 4, No. 3, pp. 273–280, 2017.

Kwak, R., Park, H.-H., Ko, H., Seong, M., Kwak, M. K., and Jeong, H. E., “Partially Cured Photopolymer with Gradient Bingham Plastic Behaviors as a Versatile Deformable Material,” ACS Macro Letters, Vol. 6, No. 5, pp. 561–565, 2017.

Ngo, C.-V., Davaasuren, G., Oh, H.-S., and Chun, D.-M., “Transparency and Superhydrophobicity of Cone-Shaped Micropillar Array Textured Polydimethylsiloxane,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 7, pp. 1347–1353, 2015.

Seong, M., Jeong, C., Yi, H., Park, H.-H., Bae, W.-G., et al., “Adhesion of Bioinspired Nanocomposite Microstructure at High Temperatures,” Applied Surface Science, Vol. 413, pp. 275–283, 2017.

Jeong, H. E., Lee, J.-K., Kim, H. N., Moon, S. H., and Suh, K. Y., “A Nontransferring Dry Adhesive with Hierarchical Polymer Nanohairs,” Proceedings of the National Academy of Sciences, Vol. 106, No. 14, pp. 5639–5644, 2009.

Jeong, H. E., Lee, J.-K., Kwak, M. K., Moon, S. H., and Suh, K. Y., “Effect of Leaning Angle of Gecko-Inspired Slanted Polymer Nanohairs on Dry Adhesion,” Applied Physics Letters, Vol. 96, No. 4, Paper No. 043704, 2010.

Yi, H., Hwang, I., Lee, J. H., Lee, D., Lim, H., et al., “Continuous and Scalable Fabrication of Bioinspired Dry Adhesives via a Rollto-Roll Process with Modulated Ultraviolet-Curable Resin,” ACS Applied Materials & Interfaces, Vol. 6, No. 16, pp. 14590–14599, 2014.

Jeong, H. E., Lee, S. H., Kim, P., and Suh, K. Y., “Stretched Polymer Nanohairs by Nanodrawing,” Nano Letters, Vol. 6, No. 7, pp. 1508–1513, 2006.

Jeong, H. E. and Suh, K. Y., “Nanohairs and Nanotubes: Efficient Structural Elements for Gecko-Inspired Artificial Dry Adhesives,” Nano Today, Vol. 4, No. 4, pp. 335–346, 2009.

Kim, T. I., Jeong, H. E., Suh, K. Y., and Lee, H. H., “Stooped Nanohairs: Geometry-Controllable, Unidirectional, Reversible, and Robust Gecko-Like Dry Adhesive,” Advanced Materials, Vol. 21, No. 22, pp. 2276–2281, 2009.

Sethi, S., Ge, L., Ci, L., Ajayan, P. M., and Dhinojwala, A., “Gecko-Inspired Carbon Nanotube-Based Self-Cleaning Adhesives,” Nano Letters, Vol. 8, No. 3, pp. 822–825, 2008.

Yi, H., Hwang, I., Sung, M., Lee, D., Kim, J.-H., et al., “Bio-Inspired Adhesive Systems for Next-Generation Green Manufacturing,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 4, pp. 347–351, 2014.

Chu, W.-S., Kim, C.-S., Lee, H.-T., Choi, J.-O., Park, J.-I., et al., “Hybrid Manufacturing in Micro/Nano Scale: A Review,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 1, No. 1, pp. 75–92, 2014.

Jahan, M., Wong, Y., and Rahman, M., “A Study on the Quality Micro-Hole Machining of Tungsten Carbide by Micro-EDM Process Using Transistor and RC-Type Pulse Generator,” Journal of Materials Processing Technology, Vol. 209, No. 4, pp. 1706–1716, 2009.

Nouraei, H., Kowsari, K., Spelt, J., and Papini, M., “Surface Evolution Models for Abrasive Slurry Jet Micro-Machining of Channels and Holes in Glass,” Wear, Vol. 309, No. 1, pp. 65–73, 2014.

Sen, M. and Shan, H. S., “A Review of Electrochemical Macro-to Micro-Hole Drilling Processes,” International Journal of Machine Tools and Manufacture, Vol. 45, No. 2, pp. 137–152, 2005.

Yan, Y., Hu, Z., Zhao, X., Sun, T., Dong, S., and Li, X., “Top-Down Nanomechanical Machining of Three-Dimensional Nanostructures by Atomic Force Microscopy,” Small, Vol. 6, No. 6, pp. 724–728, 2010.

Zhang, Q., Zhang, F., Medarametla, S. P., Li, H., Zhou, C., and Lin, D., “3D Printing of Graphene Aerogels,” Small, Vol. 12, No. 13, pp. 1702–1708, 2016.

Cho, M. H. and Park, S., “Micro CNC Surface Texturing on Polyoxymethylene (POM) and Its Tribological Performance in Lubricated Sliding,” Tribology International, Vol. 44, No. 7, pp. 859–867, 2011.

Yan, Y., Sun, T., Liang, Y., and Dong, S., “Investigation on AFMBased Micro/Nano-CNC Machining System,” International Journal of Machine Tools and Manufacture, Vol. 47, No. 11, pp. 1651–1659, 2007.

Do, V.-C., Nguyen, D.-T., Cho, J.-H., and Kim, Y.-S., “Incremental Forming of 3D Structured Aluminum Sheet,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 2, pp. 217–223, 2016.

Fan, W., Lee, C.-H., and Chen, J.-H., “Real-Time Repairable Interpolation Scheme for CNC Tool Path Processing,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 12, pp. 1673–1684, 2016.

Kim, T., “Simulated Annealing Approach with an Exhaustive Greedy Search for the Optimal Machining Region Decomposition in CNC Roughing Tool Path Generation,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 2, pp. 399–402, 2015.

Torres, F. and Griffin, J., “Control with Micro Precision in Abrasive Machining through the Use of Acoustic Emission Signals,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 3, pp. 441–449, 2015.

Bae, W.-G., Kim, D., and Suh, K.-Y., “Instantly Switchable Adhesion of Bridged Fibrillar Adhesive via Gecko-Inspired Detachment Mechanism and Its Application to a Transportation System,” Nanoscale, Vol. 5, No. 23, pp. 11876–11884, 2013.

Boesel, L. F., Greiner, C., Arzt, E., and Del Campo, A., “Gecko-Inspired Surfaces: A Path to Strong and Reversible Dry Adhesives,” Advanced Materials, Vol. 22, No. 19, pp. 2125–2137, 2010.

Lee, J., Fearing, R. S., and Komvopoulos, K., “Directional Adhesion of Gecko-Inspired Angled Microfiber Arrays,” Applied Physics Letters, Vol. 93, No. 19, Paper No. 191910, 2008.

Koschwanez, J. H., Carlson, R. H., and Meldrum, D. R., “Thin PDMS Films Using Long Spin Times or Tert-Butyl Alcohol as a Solvent,” PLoS One, Vol. 4, No. 2, Paper No. e4572, 2009.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Hwang, I., Yi, H., Choi, J. et al. Fabrication of bioinspired dry adhesives by CNC machining and replica molding. Int. J. Precis. Eng. Manuf. 18, 1239–1244 (2017). https://doi.org/10.1007/s12541-017-0145-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0145-x