Abstract

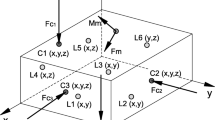

Machining fixtures which utilize screw-or strap clamps are widely used in manufacturing. Typical for them is that the cutting forces are balanced by the friction forces which act on the contact surfaces (interfaces) between clamping elements (screw- or strap clamps) and workpiece. This paper analyses load capacity and compliance of these interfaces. In order to increase their load capacity and reduce compliance, a method is proposed which is based on indenting sharp cone-shaped clamping elements into workpiece material using appropriate surfaces which are not machined, and are not expected to satisfy any particular aesthetic demands (most often castings and forgings). The results of numerical simulations and experimental investigation reveal substantial advantages of the proposed clamping method, offering possibility for industrial application and further investigation.

Similar content being viewed by others

References

Chun, S. H. and Ko, T. J., “Study on the response surface model of machining error in internal lathe boring,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 177–182, 2011.

Vukelic, D., Zuperl, U., and Hodolic, J., “Complex system for fixture selection, modification, and design,” Int. J. Adv. Manuf. Technol., Vol. 45, No. 7, pp. 731–748, 2009.

Munawar, M., Chen, J., and Mufti, N., “Investigation of cutting parameters effect for minimization of sur face roughness in internal turning,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 1, pp. 121–127, 2011.

Vukelic, D., Ostojic, G., Stankovski, S., Lazarevic, M., Tadic, B., Hodolic, J., and Simeunovic, N., “Machining fixture assembly/disassembly in RFID environment,” Assem. Autom., Vol. 31, No. 1, pp. 62–68, 2011.

Bi, Z. M. and Zhang, W. J., “Flexible fixture design and automation: Review, issues and future directions,” Int. J. Prod. Res., Vol. 39, No. 13, pp. 2867–2894, 2001.

Wan, X. J., Hua, L., Wang, X. F., Peng, Q. Z., and Qin, X. P., “An error control approach to tool path adjustment conforming to the deformation of thin-walled workpiece,” Int. J. Mach. Tools Manuf., Vol. 51, No. 3, pp. 221–229, 2011.

Amaral, N., Rencis, J. J., and Rong, Y., “Development of a finite element analysis tool for fixture design integrity verification and optimisation,” Int. J. Adv. Manuf. Technol., Vol. 25, No. 5, pp. 409–419, 2005.

Asante, J. N., “A combined contact elasticity and finite elementbased model for contact load and pressure distribution calculation in a frictional workpiece-fixture system,” Int. J. Adv. Manuf. Technol., Vol. 39, No. 5–6, pp. 578–588, 2008.

Chen, W., Ni, L., and Xue, J., “Deformation control through fixture layout design and clamping force optimization,” Int. J. Adv. Manuf. Technol., Vol. 38, No. 9, pp. 860–867, 2008.

De Meter, E. C., Xie, W., Choudhuri, S., Vallapuzha, S., and Trethewey, M. W., “A model to predict minimum required clamp pre-loads in light of fixture-workpiece compliance,” Int. J. Mach. Tools Manuf., Vol. 41, No. 7, pp. 1031–1054, 2001.

Hamedi, M., “Intelligent fixture design through a hybrid system of artificial neural network and genetic algorithm,” Artif. Intell. Rev., Vol. 23, No. 3, pp. 295–311, 2005.

Hockenberger, M. J. and DeMeter, E. C., “The application of meta functions to the quasi-static analysis of workpiece displacement within a machining fixture,” J. Manuf. Sci. Eng.-Trans. ASME., Vol. 118, No. 3, pp. 325–331, 1996.

Huang, Y. and Wang, L., “Realizing high accuracy machining by applying optimal clamping forces,” Int. J. Comput. Appl. Technol., Vol. 19, No. 2, pp. 107–118, 2004.

Kashyap, S. and DeVries, W. R., “Finite element analysis and optimization in fixture design,” Struct. Optim., Vol. 18, No. 2–3, pp. 193–201, 1999.

Kaya, N., “Machining fixture locating and clamping position optimization using genetic algorithms,” Comput. Ind., Vol. 57, No. 2, pp. 112–120, 2006.

Krishnakumar, K. and Melkote, S. N., “Machining fixture layout optimization using the genetic algorithm,” Int. J. Mach. Tools Manuf., Vol. 40, No. 4, pp. 579–598, 2000.

Kulankara, K., Satyanarayana, S., and Melkote, S. N., “Iterative fixture layout and clamping force optimization using the genetic algorithm,” J. Manuf. Sci. Eng.-Trans. ASME., Vol. 124, No. 1, pp. 119–125, 2002.

Liao, Y. J., Hu, S. J., and Stephenson, D. A., “Fixture layout optimization considering workpiece-fixture contact interaction: simulation results,” Trans. NAMRI/SME, Vol. 26, pp. 341–346, 1998.

Liu, S.-G., Zheng, L., Zhang, Z.-H., Li, Z.-Z., and Liu, D.-C., “Optimization of the number and positions of fixture locators in the peripheral milling of a low-rigidity workpiece,” Int. J. Adv. Manuf. Technol., Vol. 33, No. 7, pp. 668–676, 2007.

Lu, Y., Qin, G., and Li, M., “A Cellular Genetic Algorithm Based Optimization of Clamping Forces for Fixture Design,” Adv. Sci. Lett., Vol. 4, No. 6–7, pp. 2342–2346, 2011.

Prabhaharan, G., Padmanaban, K. P., and Krishnakumar, R., “Machining fixture layout optimization using FEM and evolutionary techniques,” Int. J. Adv. Manuf. Technol., Vol. 32, No. 11–12, pp. 1090–1103, 2007.

Padmanaban, K. P. and Prabhaharan, G., “Dynamic analysis on optimal placement of fixturing elements using evolutionary techniques,” Int. J. Prod. Res., Vol. 46, No. 15, pp. 4177–4214, 2008.

Padmanaban, K. P., Arulshri, K. P., and Prabhakaran, G., “Machining fixture layout design using ant colony algorithm based continuous optimization method,” Int. J. Adv. Manuf. Technol., Vol. 45. No. 9–10, pp. 922–934, 2009.

Ratchev, S., Phuah, K., and Liu, S., “FEA-based methodology for the prediction of part-fixture behaviour and its applications,” J. Mater. Process. Technol., Vol. 191, No. 1–3, pp. 260–264, 2007.

Sánchez, H., Estrems, M., and Faura, F., “Fixturing analysis methods for calculating the contact load distribution and the valid clamping regions in machining processes,” Int. J. Adv. Manuf. Technol., Vol. 29, No. 5, pp. 426–435, 2006.

Satyanarayana, S. and Melkote, S. N., “Finite element modeling of fixture-workpiece contacts: single contact modeling and experimental verification,” Int. J. Mach. Tools Manuf., Vol. 44, No. 9, pp. 903–913, 2004.

Siebenaler, S. P. and Melkote, S. N., “Prediction of workpiece deformation in a fixture system using the finite element method,” Int. J. Mach. Tools Manuf., Vol. 46, No. 1, pp. 51–58, 2006.

Tan, E. Y. T., Kumar, A. S., Fuh, J. Y. H., and Nee, A. Y. C., “Modeling, analysis, and verification of optimal fixturing design,” IEEE Trans. Autom. Sci. Eng., Vol. 1, No. 2, pp. 121–132, 2004.

Vishnupriyan, S., Majumder, M. C., and Ramachandran, K. P., “Optimal fixture parameters considering locator errors,” Int. J. Prod. Res., Vol. 49, No. 21, pp. 6343–6361, 2011.

Wang, Y., Chen, X., Gindy, N., and Xie, J., “Elastic deformation of a fixture and turbine blades system based on finite element analysis,” Int. J. Adv. Manuf. Technol., Vol. 36, No. 3–4, pp. 296–304, 2008.

Wang, Y., Xie, J., Wang, Z., and Gindy, N., “A parametric FEA system for fixturing of thin-walled cylindrical components,” J. Mater. Process. Technol., Vol. 205, No. 1–3, pp. 338–346, 2008.

Xiong, C. H., Wang, M. Y., and Xiong, Y. L., “On Clamping Planning in Workpiece-Fixture Systems,” IEEE Trans. Autom. Sci. Eng., Vol. 5, No. 3, pp. 407–419, 2008.

Zuperl, U., Cus, F., and Vukelic, D., “Variable clamping force control for an inteligent fixturing,” J. Prod. Eng., Vol. 14, No. 1, pp. 19–22, 2011.

Hurtado, J. F. and Melkote, S. N., “Workpiece-fixture static friction under dynamic loading,” Wear, Vol. 231, No. 1, pp. 139–152, 1999.

Liao, Y. G. and Hu, S. J., “An Integrated Model of a Fixture-Workpiece System for Surface Quality Prediction,” Int. J. Adv. Manuf. Technol., Vol. 17, No. 11, pp. 810–818, 2001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tadic, B., Jeremic, B., Todorovic, P. et al. Efficient workpiece clamping by indenting cone-shaped elements. Int. J. Precis. Eng. Manuf. 13, 1725–1735 (2012). https://doi.org/10.1007/s12541-012-0227-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0227-8