Abstract

Hot compression experiments are conducted on the Gleeble-3500 device to study the flow behaviors and hot workability of typical ultrahigh strength steel (UHSS) during the isothermal forging process. An improved Johnson–Cook (J–C) constitutive model is proposed to describe the flow behaviors, which considers the interaction effect of different deformation parameters. The proposed constitutive model shows a high prediction accuracy with an average absolute error of 5.07%. Furthermore, according to the critical strain and the logarithm of the Zener–Hollomon parameter, the mathematical models for the distribution and size of austenite grains are established, which can be used to quantitatively evaluate the effects of dynamic recrystallization (DRX) on the microstructure evolution. Considering the importance of microstructures, a new evaluation approach for hot workability is proposed, which integrates the grain size and DRX degree in the traditional processing maps. In comparison to the traditional processing maps, the newly proposed optimization method can assure the full occurrence of DRX, uniformity and fineness of grains, and absence of flow instability within the optimized processing parameter range. The processing parameters can be optimized to 0.01–0.075 s−1 and 1263–1363 K by the newly proposed evaluation approach. The average grain size of the UHSS is 20.85–40.66 μm within the optimized processing parameters, which well meets the grain size requirements for forgings.

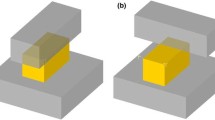

Graphical Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

D.X. Wen, C.X. Gao, Z.Z. Zheng, K. Wang, Y.B. Xiong, J.K. Wang, J.J. Li, J. Mater. Res. Technol. 13, 1684–1697 (2021). https://doi.org/10.1016/j.jmrt.2021.05.100

M.J. Zhao, L. Huang, R. Zeng, D.X. Wen, H.L. Su, J.J. Li, Mater. Sci. Eng. A 765, 138300 (2019). https://doi.org/10.1016/j.msea.2019.138300

C.M. Li, L. Huang, M.J. Zhao, X.T. Zhang, J.J. Li, P.C. Li, Mater. Sci. Eng. A 797, 139925 (2020). https://doi.org/10.1016/j.msea.2020.139925

M.J. Zhao, L. Huang, R. Zeng, H.L. Su, D.X. Wen, J.J. Li, Mater. Charact. 159, 109997 (2020). https://doi.org/10.1016/j.matchar.2019.109997

X.T. Zhong, L. Wang, L.K. Huang, F. Liu, J. Mater. Sci. Technol. 42, 241–253 (2020). https://doi.org/10.1016/j.jmst.2019.08.058

Y.B. Xiong, D.X. Wen, J.J. Li, K. Wang, Z.Z. Zheng, Met. Mater. Int. 27, 3945–3958 (2021). https://doi.org/10.1007/s12540-020-00944-x

R. Zeng, L. Huang, J.J. Li, H.W. Li, H. Zhu, X.T. Zhang, Int. J. Plast. 120, 64–87 (2019). https://doi.org/10.1016/j.ijplas.2019.04.010

R.H. Buzolin, M. Lasnik, A. Krumphals, M.C. Poletti, Int. J. Plast. 136, 102862 (2021). https://doi.org/10.1016/j.ijplas.2020.102862

S.H. Liu, Q.L. Pan, M.J. Li, X.D. Wang, X. He, X.Y. Li, Z.W. Peng, J.P. Lai, Mater. Des. 184, 108181 (2019). https://doi.org/10.1016/j.matdes.2019.108181

B. Jia, H.R. Ma, Y. Peng, Steel Res. Int. 91, 1900372 (2019). https://doi.org/10.1002/srin.201900372

P. Wan, H. Zou, K.L. Wang, Z.Z. Zhao, Met. Mater. Int. 27, 4235–4249 (2021). https://doi.org/10.1007/s12540-021-01016-4

P. Opěla, I. Schindler, P. Kawulok, R. Kawulok, S. Rusz, M. Sauer, Mater. Des. 220, 110880 (2022). https://doi.org/10.1016/j.matdes.2022.110880

G.W. Ge, Z.M. Wang, L.Q. Zhang, J.P. Lin, Mater. Today Commun. 27, 102405 (2021). https://doi.org/10.1016/j.mtcomm.2021.102405

A. Asgharzadeh, H. Asgharzadeh, A. Simchi, Met. Mater. Int. 27, 5212–5227 (2021). https://doi.org/10.1007/s12540-020-00950-z

Y.B. Xiong, D.X. Wen, Z.Z. Zheng, C.Y. Sun, J. Xie, J.J. Li, Met. Mater. Int. 29, 3009–3023 (2023). https://doi.org/10.1007/s12540-023-01428-4

X.Q. Shang, Z.S. Cui, M.W. Fu, Int. J. Mech. Sci. 144, 800–812 (2018). https://doi.org/10.1016/j.ijmecsci.2018.06.030

H. Zhu, H.A. Ou, A. Popov, Mech. Mater. 157, 103817 (2021). https://doi.org/10.1016/j.mechmat.2021.103817

M.J. Zhao, L. Huang, C.M. Li, Y. Su, S.Q. Guo, J.J. Li, C.Y. Sun, P.C. Li, Steel Res. Int. 94, 2200648 (2023). https://doi.org/10.1002/srin.202200648

Y. Liu, M. Li, X.W. Ren, Z.B. Xiao, X.Y. Zhang, Y.C. Huang, Trans. Nonferrous Met. Soc. China 30, 3031–3042 (2020). https://doi.org/10.1016/s1003-6326(20)65440-1

X.R. Chen, Q.Y. Liao, Y.X. Niu, W.T. Jia, Q.C. Le, C.L. Cheng, F.X. Yu, J.Z. Cui, J. Mater. Res. Technol. 8, 1859–1869 (2019). https://doi.org/10.1016/j.jmrt.2019.01.003

Z. Savaedi, R. Motallebi, H. Mirzadeh, J. Alloy. Compd. 903, 163964 (2022). https://doi.org/10.1016/j.jallcom.2022.163964

H.R.R. Ashtiani, A.A. Shayanpoor, Trans. Nonferrous Met. Soc. China 31, 345–357 (2021). https://doi.org/10.1016/s1003-6326(21)65500-0

Y.C. Lin, Q.F. Li, Y.C. Xia, L.T. Li, Mater. Sci. Eng. A 534, 654–662 (2012). https://doi.org/10.1016/j.msea.2011.12.023

M.J. Zhao, L. Huang, C.M. Li, J.H. Xu, X.Y. Li, J.J. Li, P.C. Li, C.Y. Sun, Acta Metall. Sin. Engl. Lett. 35, 996–1010 (2022). https://doi.org/10.1007/s40195-021-01330-1

Y. Li, P.J. Hou, Z.G. Wu, Z.L. Feng, Y. Ren, H. Choo, Mater. Des. 202, 109562 (2021). https://doi.org/10.1016/j.matdes.2021.109562

C.M. Li, Y.B. Tan, F. Zhao, J. Iron. Steel Res. Int. 27, 1073–1086 (2020). https://doi.org/10.1007/s42243-020-00462-5

R.C. Chen, P. Guo, Z.Z. Zheng, J.J. Li, F. Feng, Materials 11, 972 (2018). https://doi.org/10.3390/ma11060972

J.H. Beynon, C.M. Sellars, ISIJ Int. 32, 359–367 (1992). https://doi.org/10.2355/isijinternational.32.359

W.C. Xu, X.Z. Jin, W.D. Xiong, X.Q. Zeng, D.B. Shan, Mater Charact 135, 154–166 (2018). https://doi.org/10.1016/j.matchar.2017.11.026

Y. Guan, Y.C. Liu, Z.Q. Ma, H.J. Li, H.Y. Yu, Met. Mater. Int. 28, 1488–1498 (2022). https://doi.org/10.1007/s12540-021-01017-3

Q. Chen, L. Hu, M.G. Li, Y. Chen, L.X. Shi, T. Zhou, M.B. Yang, J. Mater. Eng. Perform. 31, 2257–2266 (2022). https://doi.org/10.1007/s11665-021-06305-y

X. Nie, S. Dong, F.H. Wang, L. Jin, Z.Y. Zhang, J. Dong, Y.Z. Wang, J. Mater. Process. Technol. 275, 116328 (2020). https://doi.org/10.1016/j.jmatprotec.2019.116328

B. Ke, L.Y. Ye, J.G. Tang, Y. Zhang, S.D. Liu, H.Q. Lin, Y. Dong, X.D. Liu, J. Alloy. Compd. 845, 156113 (2020). https://doi.org/10.1016/j.jallcom.2020.156113

M.J. Wang, W.R. Wang, Z.L. Liu, C.Y. Sun, L.Y. Qian, Mater. Today Commun. 14, 188–198 (2018). https://doi.org/10.1016/j.mtcomm.2018.01.009

D.D. Zhou, W.D. Zeng, J.W. Xu, W. Chen, S.M. Wang, Adv. Eng. Mater. 21, 1801232 (2019). https://doi.org/10.1002/adem.201801232

P. Guo, L. Deng, X.Y. Wang, J.J. Li, Sci. China Technol. Sci. 62, 1534–1544 (2019). https://doi.org/10.1007/s11431-018-9412-1

M.R. Barnett, A.G. Beer, D. Atwell, A. Oudin, Scripta Mater. 51, 19–24 (2004). https://doi.org/10.1016/j.scriptamat.2004.03.023

F.F. Liu, J.Y. Chen, J.X. Dong, M.C. Zhang, Z.H. Yao, Mater. Sci. Eng. A 651, 102–115 (2016). https://doi.org/10.1016/j.msea.2015.10.099

G.R. Johnson, W.H. Cook, Eng. Fract. Mech. 21, 31–48 (1985). https://doi.org/10.1016/0013-7944(85)90052-9

A. Shokry, S. Gowid, G. Kharmanda, Mater. Today Commun. 27, 102296 (2021). https://doi.org/10.1016/j.mtcomm.2021.102296

Z. Jia, B.L. Wei, X. Sun, J.J. Ji, Y.J. Wang, L.D. Yu, Trans. Nonferrous Met. Soc. China 32, 3259–3275 (2022). https://doi.org/10.1016/s1003-6326(22)66018-7

P. Wan, H. Zou, K.L. Wang, Z.Z. Zhao, J. Alloy. Compd. 826, 154047 (2020). https://doi.org/10.1016/j.jallcom.2020.154047

Z.W. Zhang, H. Li, Y.W. Zhou, W.M. Guo, R. Jiang, Y.J. Zhu, Steel Res. Int. 92, 2100140 (2021). https://doi.org/10.1002/srin.202100140

Z.H. Wang, W.T. Fu, B.Z. Wang, W.H. Zhang, Z.Q. Lv, P. Jiang, Mater Charact 61, 25–30 (2010). https://doi.org/10.1016/j.matchar.2009.10.001

S.K. Rajput, G.P. Chaudhari, S.K. Nath, J. Mater. Process. Technol. 237, 113–125 (2016). https://doi.org/10.1016/j.jmatprotec.2016.06.008

R.S. Qi, B.F. Guo, X.G. Liu, M. Jin, J. Iron. Steel Res. Int. 21, 1116–1123 (2014). https://doi.org/10.1016/S1006-706x(14)60192-8

B. Wu, J.B. Li, L.Z. Liu, X.H. Chen, J. Tan, J.F. Song, M. Rashad, F.S. Pan, Acta Metall. Sin. Engl. Lett. 34, 606–616 (2020). https://doi.org/10.1007/s40195-020-01163-4

Y.T. Wang, J.B. Li, Y.C. Xin, C.Z. Li, Y. Cheng, X.H. Chen, M. Rashad, B. Liu, Y. Liu, Mater. Sci. Eng. A 768, 138483 (2019). https://doi.org/10.1016/j.msea.2019.138483

Y.J. Li, Y. Zhang, Z.Y. Chen, Z.C. Ji, H.Y. Zhu, C.F. Sun, W.P. Dong, X. Li, Y. Sun, S. Yao, J. Alloy. Compd. 847, 156507 (2020). https://doi.org/10.1016/j.jallcom.2020.156507

G. Varela-Castro, J.M. Cabrera, J.M. Prado, Metals 10, 135 (2020). https://doi.org/10.3390/met10010135

P.D. Hodgson, R.K. Gibbs, ISIJ Int. 32, 1329–1338 (1992). https://doi.org/10.2355/isijinternational.32.1329

Z.M. Cai, H.C. Ji, W.C. Pei, X.F. Tang, X.M. Huang, J.P. Liu, Vacuum 165, 324–336 (2019). https://doi.org/10.1016/j.vacuum.2019.04.041

F. Chen, J. Liu, H.A. Ou, B. Lu, Z.S. Cui, H. Long, Mater. Sci. Eng. A 642, 279–287 (2015). https://doi.org/10.1016/j.msea.2015.06.093

H.J. Wang, Z.T. Hu, J.S. Cao, S. Zhang, T. Cheng, Q.Y. Wang, Met. Mater. Int. 28, 514–522 (2022). https://doi.org/10.1007/s12540-021-01057-9

Y. Liu, L.X. Du, K.B. Tu, H.Y. Wu, R.D.K. Misra, Steel Res. Int. 90, 1900114 (2019). https://doi.org/10.1002/srin.201900114

M.J. Zhao, L. Huang, C.M. Li, J.J. Li, P.C. Li, Mater. Sci. Eng. A 810, 141031 (2021). https://doi.org/10.1016/j.msea.2021.141031

S.Y. Jiang, Y. Wang, B.Y. Yan, Y.Q. Zhang, J. Alloy. Compd. 806, 1153–1165 (2019). https://doi.org/10.1016/j.jallcom.2019.07.316

D.D. Lu, J.F. Li, Y.J. Guo, P.C. Ma, Y.L. Chen, X.H. Zhang, K. Zhang, R.F. Zhang, Met. Mater. Int. 29, 1652–1668 (2023). https://doi.org/10.1007/s12540-022-01319-0

X.F. Ding, F.Q. Zhao, Y.H. Shuang, L.F. Ma, Z.B. Chu, C.J. Zhao, J. Mater. Process. Technol. 276, 116325 (2020). https://doi.org/10.1016/j.jmatprotec.2019.116325

J.H. Zhao, Y.L. Deng, F.S. Xu, J. Zhang, Metals 9, 110 (2019). https://doi.org/10.3390/met9020110

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 52305373), Jiangxi Provincial Natural Science Foundation (Grant No. 20232BAB214053), Science and Technology Major Project of Jiangxi, China (Grant No. 20194ABC28001), and PhD Starting Foundation of Nanchang Hangkong University (No. 2030009401101).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

There are no conflicts of interest to declare

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, M., Li, C., Jiang, L. et al. Hot Workability of a Typical Ultrahigh Strength Steel During the Isothermal Forging Process. Met. Mater. Int. 30, 1055–1071 (2024). https://doi.org/10.1007/s12540-023-01560-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01560-1