Abstract

In recent years, high entropy alloys (HEA) have gained much attention due to their high corrosion resistance and mechanical properties. As a target, a high entropy TiTaMoVZr alloy with a atomic ratio of 20% was cast. Following that, the Ti–6Al–4V substrate was coated using the radio frequency magnetron sputtering technique. This process took place at a temperature of 400˚C under two different atmospheres of argon and air. HEA thin films’ mechanical, biological, and corrosion properties were investigated. The biocompatibility of these films was evaluated by MTT (3-[4,5-dimethylthiazol-2-yl]-2,5 diphenyl tetrazolium bromide) assay. Based on the results, these films formed an amorphous phase with a higher hardness than the substrate. Also, the wettability and roughness of the surface of the films were higher compared to the substrate, which improved cell viability and their adhesion to the films surface. Because of their chemical compositions and unique structures, the films were more corrosion resistant than Ti6Al4V substrates were obtained. SEM investigation showed that there were more cracks on the surface of non-oxide high entropy films compared to the high entropy oxide deposit. The oxide film had no visible cracks, and also the thickness of the oxide high entropy film was more significant than the non-oxide film, which resulted in improved corrosion properties. Also, the Polarization resistance of the non-oxide (176 × 104 Ω.cm2) and oxide (218 × 104 Ω.cm2) films increased compared to the substrate (324 × 103 Ω.cm2). Furthermore, the coated samples had higher Young’s modulus and nanohardness than Ti6Al4V samples. This was attributed to the amorphous structure and the absence of defects such as dislocations and slip planes in the coating. Cell viability was improved for coated samples, however, atmospheric change in coating conditions did not significantly affect this cell viability.

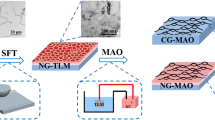

Graphical Abstract

Similar content being viewed by others

Change history

09 September 2023

A Correction to this paper has been published: https://doi.org/10.1007/s12540-023-01514-7

References

Y.S. Lee, M. Niinomi, M. Nakai, K. Narita, K. Cho, Predominant factor determining wear properties of β-type and (Α+β)-type titanium alloys in metal-to-metal contact for biomedical applications. J. Mech. Behav. Biomed. Mater. 41, 208–220 (2015). https://doi.org/10.1016/j.jmbbm.2014.10.005

L.-Y. Chen, Y.-W. Cui, L.-C. Zhang, Recent development in beta titanium alloys for biomedical applications. Metals 10, 1139 (2020). https://doi.org/10.3390/met10091139

J. Dias Corpa Tardelli, C. Bolfarini, A. Cândido dos Reis, Comparative Analysis of corrosion resistance between beta titanium and Ti-6Al-4V alloys: a systematic review. J. Trace Elem. Med. Biol. 62, 126618 (2020). https://doi.org/10.1016/j.jtemb.2020.126618

B.C. Costa, C.K. Tokuhara, L.A. Rocha, R.C. Oliveira, P.N. Lisboa-Filho, J. Costa Pessoa, Vanadium ionic species from degradation of ti-6al-4v metallic implants. In Vitro cytotoxicity and speciation evaluation. Mater. Sci. Eng. C 96, 730–739 (2019). https://doi.org/10.1016/j.msec.2018.11.090

V.B. Gupta, S. Anitha, M.L. Hegde, L. Zecca, R.M. Garruto, R. Ravid, S.K. Shankar, R. Stein, P. Shanmugavelu, K.S. Jagannatha Rao, Aluminium in Alzheimer’s disease: are we still at a crossroad? Cell. Mol. Life Sci. 62, 143–158 (2005). https://doi.org/10.1007/s00018-004-4317-3

H.A. Ching, D. Choudhury, M.J. Nine, N.A. Abu Osman, Effects of surface coating on reducing friction and wear of orthopaedic implants. Sci. Technol. Adv. Mater. 15, 014402 (2014). https://doi.org/10.1088/1468-6996/15/1/014402

P. Nagy, N. Rohbeck, G. Roussely, P. Sortais, J.L. Lábár, J. Gubicza, J. Michler, L. Pethö, Processing and characterization of a multibeam sputtered nanocrystalline CoCrFeNi high-entropy alloy film. Surf. Coat. Tech. 386, 125465 (2020). https://doi.org/10.1016/j.surfcoat.2020.125465

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375–377, 213–218 (2004). https://doi.org/10.1016/j.msea.2003.10.257

A. Xia, R. Dedoncker, O. Glushko, M.J. Cordill, D. Depla, R. Franz, In fl uence of the nitrogen content on the structure and properties of MoNbTaVW high entropy alloy thin Fi Lms. J. Alloys Compd. 850, 156740 (2021). https://doi.org/10.1016/j.jallcom.2020.156740

Q.-T. Song, J. Xu, (TiZrNbTa)90Mo10 high-entropy alloy: Electrochemical behavior and passive film characterization under exposure to Ringer’s solution. Corros. Sci. 167, 108513 (2020). https://doi.org/10.1016/j.corsci.2020.108513

A. Razazzadeh, M. Atapour, M.H. Enayati, Corrosion characteristics of TiNbMoMnFe high entropy thin film deposited on AISI316L for biomedical applications. Met. Mater. Int. 27, 2341–2352 (2021). https://doi.org/10.1007/s12540-020-00908-1

N. Tüten, D. Canadinc, A. Motallebzadeh, B. Bal, Microstructure and tribological properties of TiTaHfNbZr high entropy alloy coatings deposited on Ti–6Al–4V substrates. Intermetallics 105, 99–106 (2019). https://doi.org/10.1016/j.intermet.2018.11.015

D. Karakaş Zeybek, F. Arı, E. Ulukaya, The MTT viability assay yields strikingly false-positive viabilities although the cells are killed by some plant extracts. Tech. Res. Counc. Turkey 41, 919–925 (2017). https://doi.org/10.3906/biy-1703-104

A. Motallebzadeh, M.B. Yagci, E. Bedir, C.B. Aksoy, D. Canadinc, Communication mechanical properties of TiTaHfNbZr high-entropy alloy coatings deposited on NiTi shape memory alloy. Metall. Mater. Trans. A 49, 1992–1997 (2018). https://doi.org/10.1007/s11661-018-4605-4

N.S. Peighambardoust, A.A. Alamdari, U. Unal, A. Motallebzadeh, In vitro biocompatibility evaluation of Ti1.5ZrTa0.5Nb0.5Hf0.5 refractory high-entropy alloy film for orthopedic implants: Microstructural, mechanical properties and corrosion behavior. J. Alloys Compd. 883, 160786 (2021). https://doi.org/10.1016/j.jallcom.2021.160786.

H. Wang, J. Liu, Z. Xing, G. Ma, X. Cui, G. Jin, B. Xu, Microstructure and corrosion behaviour of AlCoFeNiTiZr high-entropy alloy films. Surf. Eng. 36, 78–85 (2020). https://doi.org/10.1080/02670844.2019.1625127

X. Yu, J. Wang, L. Wang, W. Huang, Fabrication and characterization of CrNbSiTiZr high-entropy alloy films by radio-frequency magnetron sputtering via tuning substrate bias. Surf. Coat. Tech. 412, 127074 (2021). https://doi.org/10.1016/j.surfcoat.2021.127074

C.-H. Tsau, Z.-Y. Hwang, S.-K. Chen, The microstructures and electrical resistivity of (Al, Cr, Ti)FeCoNiOx high-entropy alloy oxide thin films. Adv. Mater. Sci. Eng. 2015, 353140 (2015). https://doi.org/10.1155/2015/353140

M.-H. Tsai, J.-W. Yeh, J.-Y. Gan, Diffusion barrier properties of AlMoNbSiTaTiVZr high-entropy alloy layer between copper and silicon. Thin Solid Films 516, 5527–5530 (2008). https://doi.org/10.1016/j.tsf.2007.07.109

E. Balaur, J.M. Macak, H. Tsuchiya, P. Schmuki, Wetting behaviour of layers of TiO2 nanotubes with different diameters. J. Mater. Chem. 15, 4488–4491 (2005). https://doi.org/10.1039/b509672c

E. Salahinejad, M.J. Hadianfard, D.D. Macdonald, S. Sharifi, M. Mozafari, K.J. Walker, A. Tahmasbi Rad, S.V. Madihally, D. Vashaee, L. Tayebi, Surface modification of stainless steel orthopedic implants by Sol-Gel ZrTiO4 and ZrTiO4-PMMA coatings. J. Biomed. Nanotechnol. 9, 1327–1335 (2013). https://doi.org/10.1166/jbn.2013.1619

C.-C. Tung, J.-W. Yeh, T.-T. Shun, S.-K. Chen, Y.-S. Huang, H.-C. Chen, On the elemental effect of AlCoCrCuFeNi high-entropy alloy system. Mater. Lett. 61, 1–5 (2007). https://doi.org/10.1016/j.matlet.2006.03.140

N.T.C. Oliveira, A.C. Guastaldi, Electrochemical stability and corrosion resistance of Ti–Mo alloys for biomedical applications. Acta Biomater. 5, 399–405 (2009). https://doi.org/10.1016/j.actbio.2008.07.010

W.A. Badawy, F.M. Al-Kharafi, Corrosion and passivation behaviors of molybdenum in aqueous solutions of different pH. Electrochim. Acta 44, 693–702 (1998). https://doi.org/10.1016/S0013-4686(98)00180-7

F. Yoosefan, A. Ashrafi, S.M. Monir Vaghefi, Characterization of Co–Cr–Fe–Mn–Ni high-entropy alloy thin films synthesized by pulse electrodeposition: part 2: Effect of pulse electrodeposition parameters on the wettability and corrosion resistance. Met. Mater. Int. 27, 106–117 (2021). https://doi.org/10.1007/s12540-019-00584-w

F. Dalili, R.M. Aghdam, R. Soltani, M. Saremi, Corrosion, mechanical and bioactivity properties of HA-CNT nanocomposite coating on anodized Ti6Al4V alloy. J. Mater. Sci. Mater. Med. 33, 34 (2022). https://doi.org/10.1007/s10856-022-06655-6

M. Rahimi, R.M. Aghdam, M.H. Sohi, A.H. Rezayan, M. Ettelaei, Improving biocompatibility and corrosion resistance of anodized AZ31 Mg alloy by electrospun chitosan/mineralized bone allograft (MBA) nanocoatings. Surf. Coat. Tech. 405, 126627 (2021). https://doi.org/10.1016/j.surfcoat.2020.126627

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to the affiliation details for Author Farid Gharibi Asl were published incorrectly and the affiliation has been corrected.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gashti, M., Aghdam, R.M., Motallebzadeh, A. et al. Bio-Corrosion, Mechanical and Microstructural Properties of TiTaMoVZr High-Entropy Alloy Film on Ti–6Al–4V Substrate. Met. Mater. Int. 29, 3575–3585 (2023). https://doi.org/10.1007/s12540-023-01464-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01464-0