Abstract

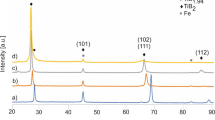

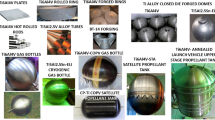

Gradient titanium alloys are more conducive to meeting the requirements of large temperature and stress gradients than single homogeneous titanium alloy components used only within specific temperature and stress ranges. In this study, the near-α high-temperature titanium alloy and Ti2AlNb intermetallic compound were combined by laser deposition technology to attempt to prepare a gradient titanium alloy that can be used in a broader temperature and stress range. The evolution characteristics of the bonding interface between the two alloys were deeply analyzed. Results show that a good metallurgical bonding interface without defects was formed after laser depositing Ti2AlNb powders on the forged near-α titanium alloy plate. The very narrow heat-affected band (HAB) and fine-grain zone were formed at the bonding interface under different laser parameters, which lead to higher microhardness than that of both sides. The chemical composition homogenization difference within and without the bonding interface should be responsible for the formation of HAB, and the solid-state transformation induced by the complex thermal history of the laser deposition process is also an essential factor. The bonding interface evolution can be generalized as the variation of phase from the substrate to the deposition zone, which is α + β→α + α’+β→β/B2. Directly laser depositing Ti2AlNb powders on the forged near-α titanium alloy plate results in the discontinuous transition of microstructure and property at the bonding interface.

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets generated during the current study are available from the corresponding author upon reasonable request.

References

C. Zhang, F. Chen, Z. Huang, M. Jia, G. Chen, Y. Ye, Y. Lin, W. Liu, B. Chen, Q. Shen, L. Zhang, E.J. Lavernia, Mater. Sci. Eng. A 764, 138209 (2019). https://doi.org/10.1016/j.msea.2019.138209

T. Lu, Y. Cui, L. Xue, H. Zhang, C. Liu, J. Mater. Sci. 56, 12438 (2021). https://doi.org/10.1007/s10853-021-06012-y

H.L. Zhu, Y. Ma, T. Wei, H.J. Li, R. Aughterson, G. Lumpkin, Addit. Manuf. 29, 100766 (2019). https://doi.org/10.1016/j.addma.2019.06.017

S.Y. Wei, W.M. Shi, D.C. Wang, Q.J. Wang, Z.Y. Chen, J.R. Liu, Chin. J. Nonferrous Met. 20, 801 (2010). https://doi.org/10.19476/j.ysxb.1004.0609.2010.s1.171

Y.H. Zhou, D.W. Wang, L.J. Song, A. Mukhtar, D.N. Huang, C. Yang, M. Yan, Mater. Sci. Eng. A 817, 141352 (2021). https://doi.org/10.1016/j.msea.2021.141352

A. Reichardt, A.A. Shapiro, R. Otis, R.P. Dillon, J.P. Borgonia, B.W. McEnerney, P. Hosemann, A.M. Beese, Int. Mater. Rev. 66, 1 (2021). https://doi.org/10.1080/09506608.2019.1709354

T. Zhang, Z. Huang, T. Yang, H. Kong, J. Luan, A. Wang, D. Wang, W. Kuo, Y. Wang, C.T. Liu, Science 374, 478 (2021). https://doi.org/10.1126/science.abj3770

Y. Liu, C. Liang, W. Liu, Y. Ma, C. Liu, C. Zhang, J. Alloys Compd. 763, 376 (2018). https://doi.org/10.1016/j.jallcom.2018.05.289

J. Cao, X.Y. Dai, J.Q. Liu, X.Q. Si, J.C. Feng, Mater. Des. 121, 176 (2017). https://doi.org/10.1016/j.matdes.2017.02.067

M. Holmquist, V. Recina, B. Pettersson, Acta Mater. 47, 1791 (1999). https://doi.org/10.1016/S1359-6454(99)00051-8

D.K.Q. Mu, Z. Zhang, Y.H. Xie, J.M. Liang, J. Wang, D.L. Zhang, Mater. Charact. 175, 111090 (2021). https://doi.org/10.1016/j.matchar.2021.111090

M.L. Su, X.Y. Qi, L.Y. Xu, Q. Feng, Y.D. Han, J. Mater. Sci. 57, 15078 (2022). https://doi.org/10.1007/S10853-022-07541-W

O. Dolev, S. Osovski, A. Shirizly, Addit. Manuf. 37, 101657 (2021). https://doi.org/10.1016/j.addma.2020.101657

J. Song, Q. Deng, C. Chen, D. Hu, Y. Li, Appl. Surf. Sci. 252, 7934 (2006). https://doi.org/10.1016/j.apsusc.2005.10.025

Y.J. Liang, X.J. Tian, Y.Y. Zhu, J. Li, H.M. Wang, Mater. Sci. Eng. A 599, 242 (2014). https://doi.org/10.1016/j.msea.2014.01.092

J. Zhou, H. Li, Y. Yu, K. Firouzian, Y. Qian, F. Lin, J. Alloys Compd. 832, 154774 (2020). https://doi.org/10.1016/j.jallcom.2020.154774

H.X. Chen, Z.Y. Liu, X. Cheng, Y. Zou, J. Alloys Compd. 875, 159946 (2021). https://doi.org/10.1016/j.jallcom.2021.159946

Y. Wu, X. Cheng, S. Zhang, D. Liu, H. Wang, Intermetallics 106, 26 (2019). https://doi.org/10.1016/j.intermet.2018.12.008

Y.Z. Zhang, Y.T. Liu, X.H. Zhao, Y.J. Tang, Mater. Des. 110, 571 (2016). https://doi.org/10.1016/j.matdes.2016.08.012

Y.T. Liu, Y.Z. Zhang, Mater. Sci. Eng. A 795, 140019 (2020). https://doi.org/10.1016/j.msea.2020.140019

Y.T. Liu, Y.Z. Zhang, Y.Q. Chen, Y.J. Tang, J. Aeronaut. Mater. 37, 61 (2017). https://doi.org/10.11868/j.issn.1005-5053.2016.00052

B. He, Y.T. Lin, G. Yang, Q.J. Zhou, X.M. Wang, IOP Conf. Ser.: Mater. Sci. Eng. 1081, 012020 (2021). https://doi.org/10.1088/1757-899X/1081/1/012020

B. He, D. Wu, J. Pan, G. Yang, Vacuum 190, 110309 (2021). https://doi.org/10.1016/j.vacuum.2021.110309

H. Tan, Z. Mi, Y. Zhu, Z. Yan, X. Hou, J. Chen, Materials 13, 552 (2020). https://doi.org/10.3390/ma13030552

M.C. Yang, MSc Dissertation, Northwestern Polytechnical University (2009), pp. 23–55

S.M. Kelly, S.L. Kampe, Metall. Mater. Trans. A 35, 1861 (2004). https://doi.org/10.1007/s11661-004-0094-8

P.A. Kobryn, E.H. Moore, S.L. Semiatin, Scr. Mater. 43, 299 (2000). https://doi.org/10.1016/S1359-6462(00)00408-5

Y.Y. Zhu, X.J. Tian, J. Li, H.M. Wang, J. Alloys Compd. 616, 468 (2014). https://doi.org/10.1016/j.jallcom.2014.07.161

C.M. Liu, H.M. Wang, X.J. Tian, H.B. Tang, D. Liu, Mater. Sci. Eng. A 586, 323 (2013). https://doi.org/10.1016/j.jallcom.2013.03.243

J.D. Hunt, Mater. Sci. Eng. 65, 75 (1984). https://doi.org/10.1016/0025-5416(84)90201-5

M.J. Bermingham, D.H. StJohn, J. Krynen, S.T. Jones, M.S. Dargusch, Acta Mater. 168, 261 (2019). https://doi.org/10.1016/j.actamat.2019.02.020

M. Bambach, I. Sizova, B. Sydow, S. Hemes, F. Meiners, J. Mater. Process. Tech. 282, 116689 (2020). https://doi.org/10.1016/j.jmatprotec.2020.116689

N. Sridharan, Y. Chen, P. Nandwana, R.M. Ulfig, D.J. Larson, S.S. Babu, J. Mater. Sci. 55, 1715 (2020). https://doi.org/10.1007/s10853-019-03984-w

Z.B. Zhao, Q.J. Wang, J.R. Liu, R. Yang, Acta Mater. 131, 305 (2017). https://doi.org/10.1016/j.actamat.2017.04.007

S. Balachandran, A. Kashiwar, A. Choudhury, D. Banerjee, R. Shi, Y. Wang, Acta Mater. 106, 374 (2016). https://doi.org/10.1016/j.actamat.2016.01.023

J. Ma, Y. Zhang, J. Li, D. Cui, J. Wang, Mater. Sci. Eng. A 811, 140984 (2021). https://doi.org/10.1016/j.msea.2021.140984

Y. Zhu, X. Tian, J. Li, H. Wang, J. Alloys Compd. 616, 468 (2014). https://doi.org/10.1016/j.jallcom.2014.07.161

C.M. Liu, X.J. Tian, H.B. Tang, H.M. Wang, J. Alloys Compd. 572, 17 (2013). https://doi.org/10.1016/j.jallcom.2013.03.243

W. Guo, R. Sun, B. Song, Y. Zhu, F. Li, Z. Che, B. Li, C. Guo, L. Liu, P. Peng, Surf. Coat. Tech. 349, 503 (2018). https://doi.org/10.1016/j.surfcoat.2018.06.020

B. Dhakal, S. Swaroop, J. Mater. Process. Tech. 282, 116640 (2020). https://doi.org/10.1016/j.jmatprotec.2020.116640

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 51974259), the Xi’an Municipal Bureau of Science and Technology (No. 21ZCZZHXJS-QCY6-0008), Foundation of Equipment Pre-Research Area (No. 80923010402) and Industry-Academic Cooperation Project of Aero Engine Corporation of China (No. HFZL2020CXY021).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Statements and Declarations

Conflict of interest The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, N., Zhao, Z.L., Liu, Y.L. et al. Bonding Interface Evolution Characteristics of Laser Depositing Ti2AlNb Intermetallic Compound on the Near-α Titanium Alloy Plate. Met. Mater. Int. 29, 2795–2806 (2023). https://doi.org/10.1007/s12540-023-01422-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01422-w