Abstract

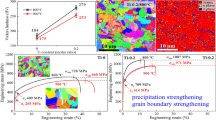

Microstructure characteristics and mechanical behavior of AA2099 Al–Li alloy with no pre-existing Li-containing precipitates (AA2099-1 sample), pre-existing δ′ precipitates (AA2099-2 sample), pre-existing T1 phase (AA2099-3 sample) and pre-existing T2 phase (AA2099-4 sample) are systematically investigated via isothermal uniaxial compression at 250 °C in the present study. Experimental results demonstrate that at the onset of plastic deformation, dynamic precipitation of small-sized T1 phase occurs rapidly within AA2099-1 sample, while it will be hindered within AA2099-2 sample. The increasing plastic strain benefits to dynamic precipitation of small-sized T1 phase in AA2099-2 sample. Consequently, AA2099-1 and AA2099-2 samples possess similar and intermediate mechanical behaviors. In terms of AA2099-3 sample, the existence of large-sized T1 phase results in the maximum yielding stress. However, some regions within these large-sized T1 precipitates are suspected to be sheared by cross-slip, leading to the destruction of crystallographic structure and the formation of Al matrix intervals. This aspect is responsible for the gradual degradation in true stress-strain curve after peak stress. As for AA2099-4 sample, dynamic precipitation rarely happens during plastic deformation and the interaction between dislocation and the pre-existing T2 phase belongs to Orowan looping, resulting in the minimal mechanical response. Besides, AA2099-1 sample possesses the average minimum deviation angle (MDA) of ~ 16.5° between the loading direction and the <110> crystal direction, whereas AA2099-4 sample owns the average MDA of ~ 7.5°. The difference in MDA is mainly attributed to δ′ phase and T1 phase, which will separately accelerate and postpone the rotation of orientation towards the <110> crystal direction.

Graphic Abstract

Similar content being viewed by others

References

A.A. El-Aty, Y. Xu, X.Z. Guo, S.H. Zhang, Y. Ma, D.Y. Chen, J. Adv. Res. 10, 49 (2018)

A. Deschamps, B. Decreus, F. De Geuser, T. Dorin, M. Weyland, Acta Mater. 61, 4010 (2013)

Ph. Lequeu, K.P. Smith, A. Daniélou, J. Mater. Eng. Perform. 19, 841 (2010)

S. Nouri, S. Sahmani, M. Hadavi, Sh Mirdamadi, Met. Mater. Int. 26, 1134 (2020)

A. Ghosh, A. Adesola, J.A. Szpunar, A.G. Odeshi, N.P. Gurao, Mater. Design 81, 1 (2015)

Q. Wen, W.Y. Li, V. Patel, Y.J. Gao, A. Vairis, Met. Mater. Int. 26, 1830 (2020)

E.J. Lavernia, T.S. Srivatsan, F.A. Mohamed, J. Mater. Sci. 25, 1137 (1990)

E.J. Lavernia, N.J. Grant, J. Mater. Sci. 22, 1521 (1987)

Z. Gao, J.Z. Liu, J.H. Chen, S.Y. Duan, Z.R. Liu, W.Q. Ming, C.L. Wu, J. Alloy. Compd. 624, 22 (2015)

C. Bartges, M.H. Tosten, P.R. Howell, E.R. Ryba, J. Mater. Sci. 22, 1663 (1987)

K.S. Prasad, A.K. Mukhopadhyay, A.A. Gokhale, D. Banerjee, D.B. Goel, Scripta Metal. Mater. 30, 1299 (1994)

X.S. Yang, W.J. Huang, X.H. Zhu, F. Guo, Y.L. Ma, L.J. Chai, R. Zhang, Met. Mater. Int. (2020). doi: https://doi.org/10.1007/s12540-020-00670-4

T. Dorin, F. De Geuser, W. Lefebvre, C. Sigli, A. Deschamps, Mater. Sci. Eng. A 605, 119 (2014)

C.V. Singh, D.H. Warner, Metall. Mater. Trans. A 44, 2625 (2013)

M. Lewandowska, J. Mizera, J.W. Wyrzykowski, Mater. Charact. 45, 195 (2000)

A.K. Vasudévan, M.A. Przystupa, W.G. Fricke Jr., Mater. Sci. Eng. A 196, 1 (1995)

J.F. Nie, B.C. Muddle, Mater. Sci. Eng. A 319, 448 (2001)

X.S. Yang. L.J. Chai, W.J. Huang, Y.L. Ma, Z.H. Zhang, Mater. Chem. Phys. 191, 99 (2017)

F. Bachmann, R. Hielscher, H. Schaeben, Solid State Phenom. 160, 63 (2010)

X.S. Yang, L.J. Chai, W.J. Huang, Y.L. Ma, Z.H. Zhang, Mater. Sci. Eng. A 675, 431 (2016)

P.S. Bate, F.J. Humphreys, N. Ridley, B. Zhang, Acta Mater. 53, 3059 (2005)

H. Ovri, E.T. Lilleodden, Acta Mater. 89, 88 (2015)

K.M. Knowles, W.M. Stobbs, Acta Crystallogr. B 44, 207 (1988)

C. Dwyer, M. Weyland, L.Y. Chang, B.C. Muddle, Dwyer, Appl. Phys. Lett. 98, 201909 (2011)

B.Q. Li, F.E. Wawner, Acta Mater. 46, 5483 (1998)

X.S. Yang, W.J. Huang, X.H. Zhu, F. Guo, L. Hu, R. Zhang, Mater. Charact. 162, 110186 (2020)

A.A. Csontos, E.A. Starke, Int. J. Plasticity 21, 1097 (2005)

P.S. De, R.S. Mishra, J.A. Baumann, Acta Mater. 59, 5946 (2011)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51871038).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, L., Li, M., Huang, W. et al. Microstructure Evolution and Mechanical Properties of AA2099 Al–Li Alloy with Tailored Li‐Containing Precipitates in Uniaxial Compression at Medium Temperature. Met. Mater. Int. 28, 1129–1142 (2022). https://doi.org/10.1007/s12540-021-00977-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-00977-w