Abstract

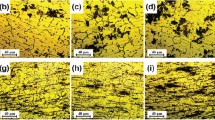

The microstructures, hardness and tensile properties of Al–AlSb-xCu in situ composites have been studied where the amount of Sb was 10 wt% and Cu contents were 1, 3, 5, 7 and 10 wt% Cu. Microstructural studies indicated that depending Cu content, the crystals of primary AlSb alter seriously in shape and size, and also a new Cu-intermetallic (Al2Cu) is formed in the as-cast microstructure. Although T6 heat treatment did not affect primary AlSb phase, extrusion process refined it through fragmentation mechanism. A uniform microstructure including well distributed fine primary AlSb particles was found by adding 5 wt% Cu to the Al–AlSb composite, as an optimum content. The variation of hardness results with Cu addition showed an increasing trend, while tensile testing examinations revealed that by exceeding Cu content (> 5 wt%), the ultimate tensile strength (UTS) of the composites is reduced in both as-cast and T6 states. The effect of heat treatment on elongation improvement of the extruded composite was positive; however, it was reverse in as-cast condition, since extruded specimens showed a better response to removing the CuAl2 phase in the eutectic region during heat treatment. Remarkable enhancement in the UTS and elongation values of the extruded specimens, before and after heat treatment, was attributed to the extensive fragmentation of intermetallic phases and well distributed fine particles in the matrix which provided proper obstacles for dislocation motion. The fracture behavior of intermetallics in as-cast specimens showed more cleavage fracture in comparison with extruded and heat treated composites which demonstrated more dimples.

Graphic Abstract

Similar content being viewed by others

References

R. Joseph Davis, Aluminum and Aluminum Alloys (ASM International, Cleveland, 1993)

M.O. Bodunrin, K.K. Alaneme, L.H. Chown, Aluminium matrix hybrid composites: a review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Sci. Technol. 4, 434–445 (2015)

Q. Qin, W. Li, The formation and characterization of the primary Mg2Si dendritic phase in hypereutectic Al–Mg2Si alloys. Mater. Trans. 57, 85–90 (2016)

S. Selvakumar, I. Dinaharan, R. Palanivel, B.G. Babu, Development of stainless steel particulate reinforced AA6082 aluminum matrix composites with enhanced ductility using friction stir processing. Mater. Sci. Eng. A 685, 317–326 (2017)

J. Selvam, D. Raja, I. Dinaharan, In-situ formation of ZrB2 particulates and their influence on microstructure and tensile behavior of AA7075 aluminum matrix composites. Eng. Sci. Technol. Int. J. 20(1), 187–196 (2017)

U. Pandey, R. Purohit, P. Agarwal, S.K. Dhakad, R.S. Rana, Effect of TiC particles on the mechanical properties of aluminium alloy metal matrix composites (MMCs). Mater. Today Proc. 4(4), 5452–5460 (2017)

M.T. Alam, A.H. Ansari, S. Arif, M.N. Alam, Mechanical properties and morphology of aluminium metal matrix nanocomposites-stir cast products. Adv. Mater. Process. Technol. 3(4), 600–615 (2017)

N. Gangil, A.N. Siddiquee, S. Maheshwari, Aluminium based in situ composite fabrication through friction stir processing: a review. J. Alloys Compd. 715, 91–104 (2017)

R.C. Sharma, M. Srivastava, Phase equilibria calculations of Al–Sb, Al–Ga and Al–Ga–Sb systems. Calphad 16(4), 387–408 (1992)

Y. Wang, Z. Zhang, S. Zheng, X. Bian, TEM observations of a rapidly solidified Al-20 Sb alloy. J. Alloys Compd. 370(1), 159–163 (2004)

M. Paliwal, J. In-Ho, Thermodynamic modeling of the Al–Bi, Al–Sb, Mg-Al-Bi and Mg–Al–Sb systems. Calphad 34(1), 51–63 (2010)

Ü. Cöcen, K. Önel, Ductility and strength of extruded SiCp/aluminium-alloy composites. Compos. Sci. Technol 62, 275–282 (2002)

R. Rahmani Fard, F. Akhlaghi, Effect of extrusion temperature on the microstructure and porosity of A356-SiCp composites. J. Mater. Process. Technol. 187–188, 433–436 (2007)

A. Bahrami, A. Razaghian, M. Emamy, H.R. Jafari, G.S. Mousavi, Microstructure and tensile properties of Al-15 wt% Mg2Si composite after hot extrusion and heat treatment. Key Eng. Mater. 47, 1171–1176 (2011)

A. Montajbnia, B. Pourbahai, M. Emamy, The microstructure and tensile properties of a newly developed Mg–Al/Mg3Sb2 in situ composite in as-cast and extruded conditions. Met. Mater. Int. 24, 1099–1111 (2018)

M. Emamy, A.B. Eradi-Zare, K. Tavighi, B. Pourbahari, Improvement in tensile and wear properties of as-cast Al–15% Mg2Si composite modified by Zn and Ni. Int. J. Metalcasting 11(4), 790–801 (2017)

M. Emamy, M. Oliayee, K. Tavighi, Microstructures and tensile properties of Al/2024–Al 4 Sr composite after hot extrusion and T6 heat treatment. Mater. Sci. Eng. A 625, 303–310 (2015)

Q.D. Qin, Y.G. Zhao, C. Liu, P.J. Cong, W. Zhou, Strontium modification and formation of cubic primary Mg2Si crystals in Mg2Si/Al composite. J. Alloys Compd. 454, 142–146 (2007)

S. Wang, C. Fan, Crystal structures of Al2Cu revisited: understanding existing phases and exploring other potential phases. Metals 9, 1037 (2019)

J.L. Murray, The aluminium-copper system. Int. Met. Rev. 30, 211–233 (1985)

D. Minić, M. Premović, V. Ćosović, D. Manasijević, D. Zivković, A. Kostov, N. Talijan, Experimental investigation and thermodynamic calculations of the Al–Cu–Sb phase diagram. J Alloys Compd. 555, 347–356 (2013)

C. Girard, J.M. Miane, J. Riou, R. Baret, J.P. Bros, Enthalpy of formation of Al–Sb and Al–Ga–Sb liquid alloys. J. Less Common Met. 128, 101–115 (1987)

M. Emamy, A.R. Emami, K. Tavighi, The effect of Cu addition and solution heat treatment on the microstructure, hardness and tensile properties of Al–15%Mg2Si–0.15%Li composite. Mater. Sci. Eng. A 576, 36–44 (2013)

R. Ivanov, A. Deschamps, F. Geuser, High throughput evaluation of the effect of Mg concentration on natural ageing of Al–Cu–Li–(Mg) alloys. Scr. Mater. 150, 156–159 (2018)

P. Wang, C. Gammer, F. Brenne, K.G. Prashanth, R.G. Mendes, M.H. Rümmeli, T. Gemming, J. Eckert, S. Scudinoa, Microstructure and mechanical properties of a heat-treatable Al–3.5Cu–1.5 Mg–1Si alloy produced by selective laser melting. Mater. Sci. Eng. A 711, 562–570 (2018)

C. Xu, R. Zheng, S. Hanada, W. Xiao, C. Ma, Effect of hot extrusion and subsequent T6 treatment on the microstructure evolution and tensile properties of an Al–6Si–2Cu–0.5 Mg alloy. Mater. Sci. Eng. A 710, 102–110 (2018)

M. Khantha, D.P. Pope, V. Vitek, Dislocation generation instability and the brittle-to-ductile transition. Mater. Sci. Eng. A 192, 435–442 (1995)

R.F. Gutiérrez, F. Sket, E. Maire, F. Wilde, E. Boller, G. Requena, Effect of solution heat treatment on microstructure and damage accumulation in cast Al–Cu alloys. J. Alloys Compd. 697, 341–352 (2017)

K. Euh, J.G. Jung, E.J. Baek, J.M. Lee, H.W Kim, Effect of heat-treatment on microstructure and mechanical properties of sonicated multicomponent AlMgSiCuZn alloy. Light Metals. Springer International Publishing, pp 379–383 (2017)

M.F. Nikoo, H. Azizi, N. Parvin, H.Y. Naghibi, The influence of heat treatment on microstructure and wear properties of friction stir welded AA6061-T6/Al2O3 nanocomposite joint at four different traveling speed. J. Manuf. Process. 22, 90–98 (2016)

A. Chen, Y. Peng, L. Zhang, G. Wu, Y. Li, Microstructural evolution and mechanical properties of cast Al–3Li–1.5 Cu–0.2 Zr alloy during heat treatment. Mater. Charact. 114, 234–242 (2016)

C. Veer Singh, D.H. Warner, An atomistic-based hierarchical multiscale examination of age hardening in an Al–Cu alloy. Metall. Mater. Trans. A 44(6), 2625–2644 (2013)

H. Pan, Y. Ren, H. Fu, H. Zhao, L. Wang, X. Meng, G. Qin, Recent developments in rare-earth free wrought magnesium alloys having high strength: a review. J. Alloys Compd. 663, 321–331 (2016)

O. Bataineh, M. Almomani, Applying ANOVA and DOE to study the effect of manganese on the hardness and wear rate of artificially aged Al-4.5 wt% Cu alloys. Int. J. Cast Met. Res. 31, 56–63 (2018)

A.E. Steinman, S. Corthay, K.L. Firestein, D.G. Kvashnin, A.M. Kovalskii, A.T. Matveev, P.B. Sorokin, D.V. Golberg, D.V. Shtansky, Al-based composites reinforced with AlB2, AlN and BN phases: experimental and theoretical studies. Mater. Des. 141, 88–98 (2018)

A. Tevatia, S.K. Srivastava, The energy-based multistage fatigue crack growth life prediction model for DRMMCs. Fatigue Fract. Eng. Mater. Struct. 41(12), 2530–2540 (2018)

Acknowledgements

The authors gratefully acknowledge University of Tehran and Iran National Science Foundation for lab facilities and financial support of this work (Grant No. 90004092).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rostami, H., Emamy, M., Rasizadeh Ghani, J. et al. Elucidating the Effects of Cu and Hot-Extrusion on Tensile Properties of Al–AlSb In Situ Composite. Met. Mater. Int. 27, 2682–2695 (2021). https://doi.org/10.1007/s12540-020-00632-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00632-w