Abstract

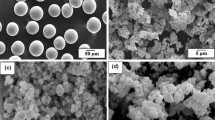

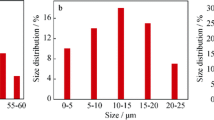

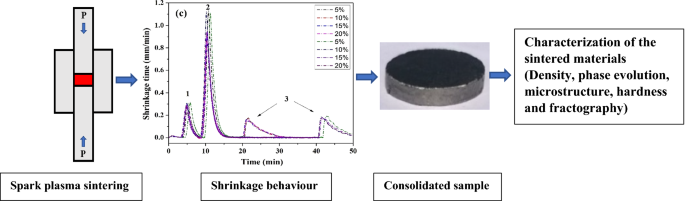

The titanium-based composite was fabricated by strengthening Ti6Al4V alloy with addition of SiAlON ceramics utilizing spark plasma sintering technique. Ti6Al4V and SiAlON powders were mixed in a T2F Turbula mixer with different proportions (5, 10, 15 and 20 vol%) and the admixed powders were consolidated using spark plasma sintering to produce titanium matrix composites. The characterization of the sintered composites was performed using X-ray diffraction, optical microscopy and scanning electron microscopy. The influence of SiAlON additions on densification, microstructure, microhardness and fracture morphology were investigated on the sintered composites. The experimental results revealed that the densification of the sintered titanium matrix composites was in the range of 95%–98%, which decreased with an increase in SiAlON addition. However, an increase in microhardness values ranging from 363 to 574 HV0.1 was achieved. The microstructure shows that the SiAlON ceramic particle was uniformly distributed within the titanium matrix composites which comprises of a mixture of lamellar colonies with β grain boundaries. The fracture features of all composites exhibit mixed fracture of both intergranular and transgranular fracture mechanism.

Graphic Abstract

Similar content being viewed by others

References

O.E. Falodun, B.A. Obadele, S.R. Oke, O.O. Ige, P.A. Olubambi, M.L. Lethabane, S.W. Bhero, Influence of spark plasma sintering on microstructure and wear behaviour of Ti–6Al–4V reinforced with nanosized TiN. Trans. Nonferr. Metals Soc. China 28, 47–54 (2018)

K. Kondoh, T. Threrujirapapong, J. Umeda, B. Fugetsu, High-temperature properties of extruded titanium composites fabricated from carbon nanotubes coated titanium powder by spark plasma sintering and hot extrusion. Compos. Sci. Technol. 72, 1291–1297 (2012)

L. Yan, W.-J. Guo, L. Ying, Bimodal-grained Ti fabricated by high-energy ball milling and spark plasma sintering. Trans. Nonferr. Metals Soc. China 26, 1170–1175 (2016)

F. Weng, C. Chen, H. Yu, Research status of laser cladding on titanium and its alloys: a review. Mater. Des. 58, 412–425 (2014)

S.C. Tjong, Y.-W. Mai, Processing-structure-property aspects of particulate-and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 68, 583–601 (2008)

H. Tsang, C. Chao, C. Ma, Effects of volume fraction of reinforcement on tensile and creep properties of in situ TiB/Ti MMC. Scripta Mater. 37, 1359–1365 (1997)

B.A. Obadele, O.E. Falodun, S.R. Oke, P.A. Olubambi, Spark plasma sintering behaviour of commercially pure titanium micro-alloyed with Ta–Ru. Part. Sci. Technol. 37, 886–892 (2019)

O.E. Falodun, B.A. Obadele, S.R. Oke, M.E. Maja, P.A. Olubambi, Effect of sintering parameters on densification and microstructural evolution of nano-sized titanium nitride reinforced titanium alloys. J. Alloys Compd. 736, 202–210 (2018)

Z.-H. Zhang, X.-B. Shen, F.-C. Wang, W. Sai, S.-K. Li, H.-N. Cai, Microstructure characteristics and mechanical properties of TiB/Ti-1.5 Fe-2.25 Mo composites synthesized in situ using SPS process. Trans. Nonferr. Metals Soc. China 23, 2598–2604 (2013)

S. Maseko, O. Fayomi, Characterization of ceramic reinforced titanium matrix composites fabricated by spark plasma sintering for anti-ballistic applications. Def. Technol. 14, 408–411 (2018)

T. Ekström, M. Nygren, SiAION ceramics. J. Am. Ceram. Soc. 75, 259–276 (1992)

F.L. Riley, Silicon nitride and related materials. J. Am. Ceram. Soc. 83, 245–265 (2000)

B. Basu, J. Vleugels, M. Kalin, O. Van Der Biest, Friction and wear behaviour of SiAlON ceramics under fretting contacts. Mater. Sci. Eng., A 359, 228–236 (2003)

N.C. Acikbas, S. Tegmen, S. Ozcan, G. Acikbas, Thermal shock behaviour of α: β-SiAlON–TiN composites. Ceram. Int. 40, 3611–3618 (2014)

O.E. Falodun, B.A. Obadele, S.R. Oke, O.O. Ige, P.A. Olubambi, Effect of TiN and TiCN additions on spark plasma sintered Ti–6Al–4V, Part. Sci. Technol. (2018). https://doi.org/10.1080/02726351.2018.1515798

R. Sivakumar, K. Aoyagi, T. Akiyama, Thermal conductivity of combustion synthesized β-sialons. Ceram. Int. 35, 1391–1395 (2009)

M.E. Maja, O.E. Falodun, B.A. Obadele, S.R. Oke, P.A. Olubambi, Nanoindentation studies on TiN nanoceramic reinforced Ti–6Al–4V matrix composite. Ceram. Int. 44, 4419–4425 (2018)

G. Cao, R. Metselaar, alpha.’-Sialon ceramics: a review. Chem. Mater. 3, 242–252 (1991)

Z. Zhang, X. Shen, F. Wang, S. Lee, L. Wang, Densification behavior and mechanical properties of the spark plasma sintered monolithic TiB2 ceramics. Mater. Sci. Eng., A 527, 5947–5951 (2010)

S. Oke, O. Ige, O. Falodun, M.R. Mphahlele, P. Olubambi, Densification behavior of spark plasma sintered duplex stainless steel reinforced with TiN nanoparticles, in: IOP Conference Series: Materials Science and Engineering, IOP Publishing, 2018, p. 012034

E. Ghasali, K. Shirvanimoghaddam, A.H. Pakseresht, M. Alizadeh, T. Ebadzadeh, Evaluation of microstructure and mechanical properties of Al–TaC composites prepared by spark plasma sintering process. J. Alloys Compd. 705, 283–289 (2017)

S.R. Oke, O.O. Ige, O.E. Falodun, A.M. Okoro, M.R. Mphahlele, P.A. Olubambi, Powder metallurgy of stainless steels and composites: a review of mechanical alloying and spark plasma sintering. Int. J. Adv. Manuf. Technol. 102, 3271–3290 (2019)

Y. Cheng, Z. Cui, L. Cheng, D. Gong, W. Wang, Effect of particle size on densification of pure magnesium during spark plasma sintering. Adv. Powder Technol. 28, 1129–1135 (2017)

S. Diouf, A. Molinari, Densification mechanisms in spark plasma sintering: effect of particle size and pressure. Powder Technol. 221, 220–227 (2012)

Y. Song, Y. Li, Z. Zhou, Y. Lai, Y. Ye, A multi-field coupled FEM model for one-step-forming process of spark plasma sintering considering local densification of powder material. J. Mater. Sci. 46, 5645–5656 (2011)

A. Taşdemirci, A. Hızal, M. Altındiş, I.W. Hall, M. Güden, The effect of strain rate on the compressive deformation behavior of a sintered Ti6Al4V powder compact. Mater. Sci. Eng., A 474, 335–341 (2008)

M.T. Jovanović, S. Tadić, S. Zec, Z. Mišković, I. Bobić, The effect of annealing temperatures and cooling rates on microstructure and mechanical properties of investment cast Ti–6Al–4V alloy. Mater. Des. 27, 192–199 (2006)

O.E. Falodun, B.A. Obadele, S.R. Oke, A.M. Okoro, P.A. Olubambi, Titanium-based matrix composites reinforced with particulate, microstructure, and mechanical properties using spark plasma sintering technique: a review. Int. J. Adv. Manuf. Technol. 102, 1689–1701 (2019)

G. Sivakumar, V. Ananthi, S. Ramanathan, Production and mechanical properties of nano SiC particle reinforced Ti–6Al–4V matrix composite. Trans. Nonferr. Metals Soc. China 27, 82–90 (2017)

D.K. Koli, G. Agnihotri, R. Purohit, Properties and characterization of Al-Al2O3 composites processed by casting and powder metallurgy routes. Int. J. Latest Trends Eng. Technol. 2, 486–496 (2013)

O. Falodun, B. Obadele, S. Oke, M. Maja, P. Olubambi, Synthesis of Ti–6Al–4V alloy with nano-TiN microstructure via spark plasma sintering technique, in: IOP conference series: Materials science and engineering, IOP Publishing, 2017, p. 012029

R. Naik, W. Pollock, W. Johnson, Effect of a high-temperature cycle on the mechanical properties of silicon carbide/titanium metal matrix composites. J. Mater. Sci. 26, 2913–2920 (1991)

Acknowledgements

The authors would like to acknowledge the Global Excellence and Stature at the University of Johannesburg and National Research Foundation, South Africa for providing the necessary financial supports. Also, the Institute of Nanoengineering Research at the Tshwane University of Technology in using spark plasma sintering facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Falodun, O.E., Oke, S.R., Obadele, B.A. et al. Influence of SiAlON Ceramic Reinforcement on Ti6Al4V Alloy Matrix via Spark Plasma Sintering Technique. Met. Mater. Int. 27, 1769–1778 (2021). https://doi.org/10.1007/s12540-019-00553-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00553-3