Abstract

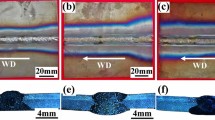

High-entropy alloys having excellent properties are particularly suitable for the application as the filler metals in welding. In the present study, multi-component mixed powders of FeCoCrNiMn and CrFeNi2.4Al0.6, based on a high-entropy design, as well as the comparative 316L stainless steel powders, were used as the filler metals, to achieve the dissimilar welding between 304 stainless steel and SMA490BW steel by laser deposition welding. By comparative analysis of the microstructure and mechanical properties of three types of joints, the feasibility and weld-ability of the filler metal powders based on a high-entropy design were studied. It was found that the melting of base metal (BM) and weld metal dilution had an impact on the set high-entropy component in the weld zone. And high-entropy structures were achieved in the weld zone by using the powders of CrFeNi2.4Al0.6. Compared to the BM of SMA490BW steel, three types of joints presented a higher notched tensile strength and had a better corrosion resistance. The joint welded using the powders of CrFeNi2.4Al0.6 had the lowest hardness value in the weld zone, in which the joint was fractured during the notched tensile tests. The other two joints fractured near the notch in the SMA490BW steel side. Transgranular fracture and a typical dimple fracture were observed in the fractured joints.

Graphic Abstract

In this work, multi-component mixed powders of FeCoCrNiMn and CrFeNi2.4Al0.6, based on a high-entropy design, were used as the filler metals to achieve the dissimilar welding of 304 stainless steel to SMA490BW steel by laser deposition welding. And a detailed investigation of microstructures and mechanical properties of those dissimilar joints was carried out to explore the feasibility and weld-ability of the filler metal powders based on a high-entropy design.

Similar content being viewed by others

References

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014)

D.B. Miracle, O.N. Senkov, Acta Mater. 122, 448 (2017)

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritchie, Science 345, 1153 (2014)

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, C.C. Tasan, Nature 534, 227 (2016)

K. Tazuddin, N.P. Biswas, Gurao. Mat. Sci. Eng. A 657, 224 (2016)

R. Li, M. Wang, T. Yuan, B. Song, Y. Shi, Metall. Mater. Trans. A 48, 841 (2016)

Z. Wu, C.M. Parish, H.J. Bei, J. Alloy. Compd. 647, 815 (2015)

G.D. Sathiaraj, P.P. Bhattacharjee, J. Alloy. Compd. 647, 82 (2015)

Ł. Rogal, Z. Szklarz, P. Bobrowski, D. Kalita, G. Garzeł, A. Tarasek, M. Kot, M. Szlezynger, Met. Mater. Int (2019). https://doi.org/10.1007/s12540-018-00236-5

X. Qiu, J. Alloy. Compd. 735, 359 (2018)

J. Joseph, N. Stanford, P. Hodgson, D.M. Fabijanic, J. Alloy. Compd. 726, 885 (2017)

X. Jin, J. Bi, L. Zhang, Y. Zhou, X. Du, Y. Liang, B. Li, J. Alloy. Compd. 770, 655 (2019)

H. Nam, C. Park, J. Moon, Y. Na, H. Kim, N. Kang, Mat. Sci. Eng. A 742, 224 (2019)

Z.G. Zhu, F.L. Ng, J.W. Qiao, P.K. Liaw, H.C. Chen, S.M.L. Nai, J. Wei, G.J. Bi, Mater. Res. Express 6, 046514 (2019)

R. Sokkalingam, K. Sivaprasad, V. Muthupandi, M. Duraiselvam, Key Eng. Mater. 775, 448 (2018)

N. Kashaev, V. Ventzke, N. Stepanov, D. Shaysultanov, V. Sanin, S. Zherebtsov, Intermetallics 96, 63 (2018)

N. Xu, Q. Song, Y. Bao, Mater. Sci. Technol. 35, 577 (2019)

Z.G. Zhu, Y.F. Sun, F.L. Ng, M.H. Goh, P.K. Liaw, H. Fujii, Q.B. Nguyen, Y. Xu, C.H. Shek, S.M.L. Nai, J. Wei, Mater. Sci. Eng. A 711, 524 (2018)

D. Shaysultanov, N. Stepanov, S. Malopheyev, I. Vysotskiy, V. Sanin, S. Mironov, R. Kaibyshev, G. Salishchev, S. Zherebtsov, Mater. Charact. 145, 353 (2018)

Z.G. Zhu, Y.F. Sun, M.H. Goh, F.L. Ng, Q.B. Nguyen, H. Fujii, S.M.L. Nai, J. Wei, C.H. Shek, Mater. Lett. 205, 142 (2017)

M.-G. Jo, H.-J. Kim, M. Kang, P.P. Madakashira, E.S. Park, J.-Y. Suh, D.-I. Kim, S.-T. Hong, H.N. Han, Met. Mater. Int. 24, 73 (2018)

A.C. Martin, C. Fink, Weld. World (2019). https://doi.org/10.1007/s40194-019-00702-7

Z. Wu, S.A. David, D.N. Leonard, Z. Feng, H. Bei, Sci. Technol. Weld. Join. (2018). https://doi.org/10.1080/13621718.2018.1430114

R. Sokkalingam, S. Mishra, S.R. Cheethirala, V. Muthupandi, K. Sivaprasad, Metall. Mater. Trans. A 48, 3630 (2017)

Z. Wu, S.A. David, Z. Feng, H. Bei, Scripta Mater. 124, 81 (2016)

H. Nam, C. Park, C. Kim, H. Kim, N. Kang, Sci. Technol. Weld. Joi. 23, 420 (2017)

D. Bridges, S. Zhang, S. Lang, M. Gao, Z. Yu, Z. Feng, A. Hu, Mater. Lett. 215, 11 (2018)

L.X. Zhang, J.M. Shi, H.W. Li, X.Y. Tian, J.C. Feng, Mater. Des. 97, 230 (2016)

I. Voiculescu, V. Geanta, I.M. Vasile, R. Stefanoiu, M. Tonoiu, J. Optoelectron. Adv. Mater. 15, 650 (2013)

Y. Liu, N. Xi, S. Fu, G. Yang, H. Fu, H. Chen, X. Zhang, N. Liu, W. Gao, Mater. Res. Express 5, 115030 (2018)

H. Ma, G. Qin, P. Geng, F. Li, B. Fu, X. Meng, Mater. Des. 86, 587 (2015)

H. Cheng, Y.-C. Xie, Q.-H. Tang, C. Rao, P.-Q. Dai, T. Nonferr, Metal. Soc. 28, 1360 (2018)

W.H. Liu, Y. Wu, J.Y. He, T.G. Nieh, Z.P. Lu, Scr. Mater. 68, 526 (2013)

X. Shi, K. Yu, L. Jiang, C. Li, Z. Li, X. Zhou, Surf. Coat. Tech. 334, 19 (2018)

H.M. Soltani, M. Tayebi, J. Alloy. Comp. 767, 112 (2018)

J.H. Kim, Y.S. Na, Met. Mater. Int. 25, 296 (2018)

J.W. Won, M. Kang, H.-J. Kwon, K.R. Lim, S.M. Seo, Y.S. Na, Met. Mater. Int. 24, 1432 (2018)

M.J. Jang, S.-H. Joo, C.-W. Tsai, J.-W. Yeh, H.S. Kim, Met. Mater. Int. 22, 982 (2016)

J.-X. Fu, C.-M. Cao, W. Tong, L.-M. Peng, Trans. Nonferr. Metal. Soc. 28, 931 (2018)

M.-H. Tsai, J.-W. Yeh, Mater. Res. Lett. 2, 107 (2014)

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008)

S. Guo, C.T. Liu, Prog. Nat. Sci. -Mater. 21, 433 (2011)

X. Yang, Y. Zhang, Mater. Chem. Phys. 132, 233 (2012)

G. Bonny, C. Domain, N. Castin, P. Olsson, L. Malerba, Comp. Mater. Sci. 161, 309 (2019)

Acknowledgements

This study was financially supported by National Natural Science Foundation of China (51805171), Natural Science Foundation in Jiangxi Province (20181BAB216021), the Opening Project of Key Laboratory of Testing Technology for Manufacturing Process (Southwest University of Science and Technology), Ministry of Education (18kfzk04), Jiangxi Provincial Department of Education (GJJ180347).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, D., Guo, R., Hu, Y. et al. Dissimilar Metal Joining of 304 Stainless Steel to SMA490BW Steel Using the Filler Metal Powders with a High-Entropy Design. Met. Mater. Int. 26, 854–866 (2020). https://doi.org/10.1007/s12540-019-00400-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00400-5