Abstract

We present a new comprehensive scheme for generating grain boundary conformed, volumetric mesh elements from a three-dimensional voxellated polycrystalline microstructure. From the voxellated image of a polycrystalline microstructure obtained from the Monte Carlo Potts model in the context of isotropic normal grain growth simulation, its grain boundary network is approximated as a curvature-maintained conformal triangular surface mesh using a set of in-house codes. In order to improve the surface mesh quality and to adjust mesh resolution, various re-meshing techniques in a commercial software are applied to the approximated grain boundary mesh. It is found that the aspect ratio, the minimum angle and the Jacobian value of the re-meshed surface triangular mesh are successfully improved. Using such an enhanced surface mesh, conformal volumetric tetrahedral elements of the polycrystalline microstructure are created using a commercial software, again. The resultant mesh seamlessly retains the short- and long-range curvature of grain boundaries and junctions as well as the realistic morphology of the grains inside the polycrystal. It is noted that the proposed scheme is the first to successfully generate three-dimensional mesh elements for polycrystals with high enough quality to be used for the microstructure-based finite element analysis, while the realistic characteristics of grain boundaries and grains are maintained from the corresponding voxellated microstructure image.

Similar content being viewed by others

References

B. Sun, Z. Suo, W. Yang, Acta Mater. 45, 1907–1915 (1997)

B. Sun, Z. Suo, Acta Mater. 45, 4953–4962 (1997)

A.F. Bower, E. Wininger, J. Mech. Phys. Solids 52, 1289–1317 (2004)

M. Nygards, P. Gudmundson, Comput. Mater. Sci. 24, 513–519 (2002)

A. Musienko, A. Tatschl, K. Schmidegg, O. Kolednik, R. Pippan, G. Cailletaud, Acta Mater. 55, 4121–4136 (2007)

H.J. Chang, H.N. Han, S.J. Park, J.H. Cho, K.H. Oh, Met. Mater. Int. 16, 553–558 (2010)

S. Manchiraju, D. Gaydosh, O. Benafan, R. Noebe, R. Vaidyanathan, P.M. Anderson, Acta Mater. 59, 5238–5249 (2011)

C. Herring, in The Physics of Powder Metallurgy, ed. by W. Kingston (McGraw-Hill, New York, 1951), p. 143

R. Quey, P.R. Dawson, F. Barbe, Comput. Methods Appl. Mech. Eng. 200, 1729–1745 (2011)

F. Barbe, R. Quey, 18 ème Congrès Français de Mécanique (2007)

C. Konke, S. Eckardt, S. Hafner, T. Luther, J. Unger, Int. J. Multiscale Comput. Eng. 8, 17–36 (2010)

Y. Bhandari, S. Sarkar, M. Groeber, M.D. Uchic, D.M. Dimiduk, S. Ghosh, Comput. Mater. Sci. 41, 222–235 (2007)

S. Ghosh, Y. BlIandari, M. Groeber, Comput.-Aided Des. 40, 293–310 (2008)

A.C.O. Miranda, L.F. Martha, P.A. Wawrzynek, A.R. Ingraffea, Eng. Comput. 25, 207–219 (2009)

S.E. Dillard, J.F. Bingert, D. Thoma, B. Hamann, I.E.E.E. Trans, Vis. Comput. Graph. 13, 1528–1535 (2007)

K. Brakke, Exp. Math. 1, 141–165 (1992)

A. Kuprat, A. Khamayseh, D. George, L. Larkey, J. Comput. Phys. 172, 99–118 (2001)

R.H. Moore, G.S. Rohrer, S. Saigal, Eng. Comput. 25, 221–235 (2009)

F. Barbe, L. Decker, D. Jeulin, G. Cailletaud, Int. J. Plast 17, 513–536 (2001)

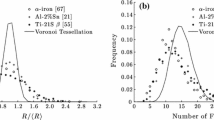

M. Tanemura, Forma 18, 221–247 (2003)

T.-C. Chen, T. Li, X. Zhang, S.B. Desu, J. Mater. Res. 12, 1569–1575 (1997)

S. Kumar, S.K. Kurtz, J.R. Banavar, M. Sharma, J. Stat. Phys. 67, 523–551 (1992)

A. Ullah, G.Q. Liu, J.H. Luan, W.W. Li, M.U. Rahman, M. Ali, Mater. Charact. 91, 65–75 (2014)

A. Ullah, G.Q. Liu, H. Wang, M. Khan, D.F. Khan, J.H. Luan, Mater. Express 3, 109–118 (2013)

J.C. Tucker, L.H. Chan, G.S. Rohrer, M.A. Groeber, A.D. Rollett, Scripta Mater. 66, 554–557 (2012)

S. Donegan, J. Tucker, A. Rollett, K. Barmak, M. Groeber, Acta Mater. 61, 5595–5604 (2013)

M. Groeber, B. Haley, M. Uchic, D. Dimiduk, S. Ghosh, Mater. Charact. 57, 259–273 (2006)

D. Rowenhorst, A. Lewis, G. Spanos, Acta Mater. 58, 5511–5519 (2010)

F. Wakai, N. Enomoto, H. Ogawa, Acta Mater. 48, 1297–1311 (2000)

W.J. Schroeder, J.A. Zarge, W.E. Lorensen, in SIGGRAPH ‘Proceedings of the 19th Annual Conference on Computer Graphics and Interactive Techniques’ (ACM, New York, 1992), pp. 65–70

D.P. Luebke, I.E.E.E. Comput, Graph. Appl. 21, 24–35 (2001)

S.B. Lee, G.S. Rohrer, A.D. Rollett, Model. Simul. Mater. Sci. Eng. 22, 21 (2014)

Z. Wu, J.M. Sullivan, Int. J. Numer. Methods Eng. 58, 189–207 (2003)

P.M. Knupp, 45th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, SAND2007-8128C, AIAA (2007)

M. Bern, D. Eppstein, J. Gilbert, J. Comput. Syst. Sci. 48, 384–409 (1994)

M. Goelke, Element quality and check (2014), http://www.altairuniversity.com. Accessed 25 July 2017

A. Hannukainen, S. Korotov, M. Křížek, Numer. Math. 120, 79–88 (2012)

T.A. Burkhart, D.M. Andrews, C.E. Dunning, J. Biomech. 46, 1477–1488 (2013)

J. Shewchuk, What is a good linear finite element? Interpolation, conditioning, anisotropy, and quality measures, University of California at Berkeley, p. 73 (2002)

R. Abgrall, J. Comput. Phys. 114, 45–58 (1994)

Wanai Li, Efficient Implementation of High-Order Accurate Numerical Methods on Unstructured Grids (Springer, Berlin, 2014), pp. 1–10

H. Ledbetter, E. Naimon, J. Phys. Chem. Ref. Data 3, 897–935 (1974)

C. Wert, E. Tyndall, J. Appl. Phys. 20, 587–589 (1949)

C. Hull, International Critical Tables of Numerical Data, Physics, Chemistry and technoLogy (National Academies, Washington, DC, 1929)

A. Alankar, I.N. Mastorakos, D.P. Field, Acta Mater. 57, 5936–5946 (2009)

D. Peirce, R.J. Asaro, A. Needleman, Acta Metall. 31, 1951–1976 (1983)

Y. Choi, T. Parthasarathy, D. Dimiduk, M. Uchic, Metall. Mater. Trans. A 37, 545–550 (2006)

Y. Choi, M. Uchic, T. Parthasarathy, D. Dimiduk, Scripta Mater. 57, 849–852 (2007)

ASM International Handbook Committee, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials (ASM International, USA, 2001)

Acknowledgements

This work was supported by the Agency for Defense Development (ADD) and by the National Research Foundation of Korea (NRF) grant funded by the Ministry of Science, ICT & Future Planning (MSIP) (No. NRF-2015R1A5A1037627).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, MJ., Jeon, YJ., Son, GE. et al. Grain Boundary Conformed Volumetric Mesh Generation from a Three-Dimensional Voxellated Polycrystalline Microstructure. Met. Mater. Int. 24, 845–859 (2018). https://doi.org/10.1007/s12540-018-0083-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-0083-x