Abstract

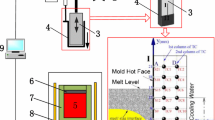

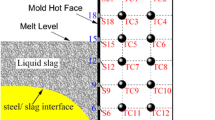

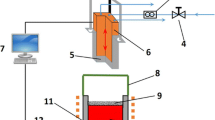

An oscillating multi-mold simulator with embedded thermocouples was used to study the initial solidification of medium carbon steels and crystallization characteristics of the mold flux. Casting speed variations in the simulator from 0.7 m/min to 1.4 m/min at fixed oscillation frequency and stroke resulted in higher copper mold temperatures. Frequency modifications from 2.5 Hz to 5.0 Hz and stroke changes from 8.1 mm to 5.4 mm at fixed casting speeds also resulted in higher copper mold temperatures. Surface profile analysis of as-cast steel strips showed characteristic oscillation marks comparable to the narrow faces of the industrial cast slabs. The apparent effect of casting variables on the temperature and surface profiles during the solidification of the medium carbon steels could be correlated to the variations in the negative strip time and subsequent changes in the extent of mold flux infiltration. Back scattered scanning electron microscope analysis of the full length of the retrieved flux film after casting showed cuspidine crystallization ratio that increased from the upper to lower portion of the flux film. This dynamic crystallization and growth of the cuspidine phase increases as the flux is sustained at high temperatures for longer periods. Additional experiments with industrial fluxes designed for soft cooling of medium carbon steel grades showed comparable infiltration thickness of the flux, but the crystallization characteristics were significantly different, which could have a significant impact on the heat transfer rate and mechanism through the flux film.

Similar content being viewed by others

References

W. Kurz, La Metallurgia Italiana 99, 56 (2008).

A. Badri, T. T. Natarajan, C. C. Snyder, K. D. Powers, F. J. Mannion, and A. W. Cramb, Metall. Mat. Trans. B 36B, 373 (2005).

I. Sohn, T. T. Natarajan, T. J. Piccone, K. D. Powers, and C. C. Snyder, European Continuous Casting Conference 2008, Riccione, Italy (2008).

G. Lesoult, J.-M. Jolivet, L. Cadeville, and Ch.-A. Gandin, Contributions to the Understanding of the Formation of the Skin during Continuous Casting of Steel, Solidification Processes and Microstructures, pp.15–26, TMS2004, USA (2004)

K. Schwerdtfeger and H. Sha, Metall. Mater. Trans. B 31B, 813 (2000).

E. Takeuchi and J. K. Brimacombe, Metall. Mater. Trans. B 15B, 493 (1984).

K. M. Park, J. H. Gu, S. M. Seo, H. W. Jeong, J. H. Shin, K. B. Sim, and J. H. Lee, Korean J. Met. Mater. 51, 211 (2013).

K.-H. Kim and C.-M. Bae, Met. Mater. Int. 19, 375 (2013).

E. S. Szekeres, Iron Steel Eng. 73, 29 (1996).

O. D. Kwon, J. Choi, I. R. Lee, J. W. Kim, K. H. Moon, and Y. K. Shin, Optimisation of Mould Oscillation Pattern for the Improvement of Surface Quality and Lubrication in Slab Continuous Casting, Proc. the 74th Steelmaking Conference, pp.561–568, Washington D.C., USA (1991).

K. Cukierski and B. G. Thomas, Metall. Mater. Trans. B 39B, 94 (2008).

R. B. Mahapatra, J. K. Brimacombe, and I. V. Samarasekera, Metall. Mater. Trans. B 22B, 875 (1991).

J. Sengupta, B. G Thomas, H.-J. Shin, G.-G. Lee, and S.-H. Kim, Metall. Mater. Trans. A 37A, 1597(2006).

M. Suzuki, H. Mizukami, T. Kitagawa, K. Kawakami, S. Uchida, and Y. Komatsu, ISIJ Int. 31, 254 (1991).

T. Gamal and U. Schoneberg, Stahlu. Eisen 112, 45 (1992).

K. C. Mills, A. B. Fox, Z. Li, and R. P. Thackray, Ironmak. Steelmak. 32, 26 (2005).

H. Tomono, W. Kurz, W. Heinemann, Metall. Mater. Trans. B 12B, 409 (1981).

M. Suzuki and Y. Yamaoka, Mater. Trans. JIM. 44, 836 (2003).

M. Kudoh, T. Takahashi, and Y. Deguchi, Tetsu-to-Hagane 73, S901 (1987).

D. Bouchard, F. G. Hamel, J.-P Nadeau, S. Bellemare, F. Dreneau, D.-A. Tremblay, and D. Sirrard, Metall. Mater. Trans. B 32B, 111 (2001).

L. Strezov and J. Herbertson, ISIJ Int. 38, 959 (1998).

P. J. Wray, Metall. Mater. Trans. B 12B, 167 (1981).

I. G. Saucedo, Proc. Steelmaking Conference, pp.79–89, Iron and Steel Society of AIME, 75, Washington D.C., USA (1991).

W. Wang, K. Gu, L. Zhon, F. Ma, I. Sohn, D. J. Min, H. Matsuura, and F. Tsukihashi, ISIJ Int. 51, 1838 (2011).

E.-Y. Ko, C. Joo, J.-Y. Park, and I. Sohn, Met. Mater. Int. 20, 141 (2014).

H. Zhang, W. Wang, and D. Zhou, Metall. Mater. Trans. B 45B, 1038 (2014).

Y. Le Papillon, W. Jaeger, M. Konig, B. Weisgerber, and M. Jauhola, Determination of High Temperature Surface Crack Formation Criteria in Continuous Casting and Thin Slab Casting, pp.1–155, European Commission Technical Steel Research, EUR20897 (2003).

M. Bobadilla, J. M. Jolivet, J.Y. Lamant, and M. Larrecq, Mater. Sci. Eng. A 173 275 (1993).

M. Hanao and M. Kawamoto, ISIJ Int. 48, 180 (2008).

R. C. Zeller and R. O. Pohl, Phys. Rev. B 4, 2029 (1971).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, JY., Ko, Ey., Choi, J. et al. Characteristics of medium carbon steel solidification and mold flux crystallization using the multi-mold simulator. Met. Mater. Int. 20, 1103–1114 (2014). https://doi.org/10.1007/s12540-014-6013-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-014-6013-7