Abstract

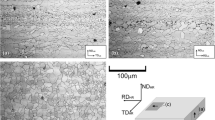

A melt treatment with a vibrating cooling slope and a semisolid rolling process to produce an AZ61 alloy strip was proposed. The microstructure formation mechanism and the properties of the AZ61 alloy produced by the proposed process were investigated. Due to the high cooling rate and stirring action caused by the vibration cooling slope, the nucleation rate was greatly improved, which caused the formation of fine spherical or rosette primary grains. During the rolling process, the solid fraction increased from the entrance to the exit of the roll gap, and under the shearing action of the roller, the distribution of solute in the melt was homogenous, and the primary grains grew further. When the casting temperature was 680 °C, a strip with a cross section of 4 mm×160 mm was produced and a homogeneous microstructure was obtained. The ultimate tensile strength of the AZ61 alloy strip produced by the proposed method reached 242 MPa, and the corresponding elongation to failure was 4%, which were better than those achieved in previous similar studies.

Similar content being viewed by others

References

M. K. Kulekci, Int. J. Adv. Manuf. Technol. 39, 851 (2008).

J. L. Kuo, S. Sugiyama, S. H. Hsiang, and J. Yanagimoto, Int. J. Adv. Manuf. Technol. 29, 670 (2006).

M. C. Flemings, Metall. Trans. A 22, 957 (1991).

R. A. Martinez and M. C. Flemings, Metall. Mater. Trans. A 36, 2205 (2005).

D. Brabazon, D. J. Browne, and A. J. Carr, Mater. Sci. Eng. A 326, 370 (2002).

M. A. Jaworski, T. K. Gray, M. Antonelli, J. J. Kim, C. Y. Lau, M. B. Lee, M. J. Neumann, W. Xu, and D. N. Ruzic, Phys. Rev. Lett. 104, 1 (2010).

R. Haghayeghia, E. J. Zoquib, N. R. Greenc, and H. Bahaia, J. Alloys Compd. 502, 382 (2010).

S. Thanabumrungkul, S. Janudom, R. Burapa, P. Dulyapraphant, and J. Wannasin, Trans. Nonferr. Met. Soc. China s3, 1016 (2010).

J. F. Jiang, Y. Wang, J. J. Qu, Z. M. Du, Y. Sun, and S. J. Luo, J. Alloys Compd. 497, 62 (2010).

J. F. Jiang, Y. Wang, J. J. Qu, Z. M. Du, and S. J. Luo, Trans. Nonferr. Met. Soc. China 20, 1731 (2010).

E. C. Legoretta, H. V. Atkinson, and H. Jones, J. Mater. Sci. 43, 5448 (2008).

R. G. Guan, Z. H. Xing, L. Shi, C. Wang, and Y. Wang, Mater. Sci. Forum 561-565, 865 (2007).

T. Haga, J. Mater. Process Technol. 130–131, 558 (2002).

E. C. Legoretta, H. V. Atkinson, and H. Jones, J. Mater. Sci. 43, 5456 (2008).

A. El-Morsy, A. Ismail, and M. Waly, Mater. Sci. Eng. A 486, 528 (2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Z.Y., Guan, R.G., Wang, X. et al. Microstructure formation mechanism and properties of AZ61 alloy processed by melt treatment with vibrating cooling slope and semisolid rolling. Met. Mater. Int. 19, 1063–1067 (2013). https://doi.org/10.1007/s12540-013-5022-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-013-5022-2