Abstract

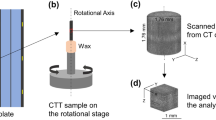

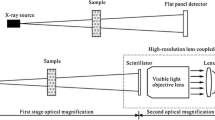

Synchrotron radiation–CT (SR–CT), as a non-invasive method to study the internal structure of materials, has been widely used in the textile field. In this study, the cotton yarn produced by different spinning processes was first packaged, and then, the CT images of the same variety of cotton yarn spun by different processes were collected by SR–CT technology, and the AI-assisted segmentation module in Avizo was used for 3D visualization characterization. The results show that SR–CT imaging technology has the advantages of high resolution and non-destructive, and can characterize the three-dimensional microstructure of yarns with sub-micron resolution, so as to obtain the structural characteristics of yarns and fiber transfer characteristics in yarns. In addition, the mechanical properties of yarns produced by different processes are compared and analyzed, and the mechanism of the difference in mechanical properties caused by the change of fiber structure in yarns is revealed.

Similar content being viewed by others

Availability of Data and Materials

All data generated or analyzed during this study are included in this published article.

References

Y.T. Gao, W. Hu, S. Xin, L. Sun, A review of applications of CT imaging on fiber reinforced composites. J. Compos. Mater. 56(1), 133–164 (2022). https://doi.org/10.1177/00219983211050705

M. Hauptmann, G. Byrnes, E. Cardis, M. Bernier, M. Blettner, J. Dabin, H. Engels, T. Istad, C. Johansen, M. Kaijser, K. Kjaerheim, N. Journy, J. Meulepas, M. Moissonnier, C. Ronckers, I. Thierry-Chef, L. Le Cornet, A. Jahnen, R. Pokora, M. Bosch de Basea, J. Figuerola, C. Maccia, A. Nordenskjold, R. Harbron, C. Lee, S. Simon, A. Berrington de Gonzalez, J. Schüz, A. Kesminiene, Brain cancer after radiation exposure from CT examinations of children and young adults: results from the EPI-CT cohort study. Lancet Oncol. 24(1), 45–53 (2023). https://doi.org/10.1016/S1470-2045(22)00655-6

T. Ishikawa, K.H. Kim, Y. Ohkoshi, Visualization of a pillar-shaped fiber bundle in a model needle-punched nonwoven fabric using X-ray micro-computed tomography. Text. Res. J. 87(11), 1387–1393 (2017). https://doi.org/10.1177/0040517516652351

Y. Mahadik, K.A.R. Brown, S.R. Hallett, Characterisation of 3D woven composite internal architecture and effect of compaction. Compos. Part A Appl. Sci. Manuf. 41(7), 872–880 (2010). https://doi.org/10.1016/j.compositesa.2010.02.019

P. Badel, E. Vidal-Sallé, E. Maire, P. Boisse, Simulation and tomography analysis of textile composite reinforcement deformation at the mesoscopic scale. Int. J. Mater. Form. 2, 189–192 (2009). https://doi.org/10.1007/s12289-009-0572-z

F. Desplentere, S.V. Lomov, D.L. Woerdeman, I. Verpoest, M. Wevers, A. Bogdanovich, Micro-CT characterization of variability in 3D textile architecture. Compos. Sci. Technol. 65(13), 1920–1930 (2005). https://doi.org/10.1016/j.compscitech.2005.04.008

P. Latil, L. Orgéas, C. Geindreau, P.J.J. Dumont, S. Rolland du Roscoat, Towards the 3D in situ characterisation of deformation micro-mechanisms within a compressed bundle of fibres. Compos. Sci. Technol. 71(4), 480–488 (2011). https://doi.org/10.1016/j.compscitech.2010.12.023

T. Fast, A.E. Scott, H.A. Bale, B.N. Cox, Topological and Euclidean metrics reveal spatially nonuniform structure in the entanglement of stochastic fiber bundles. J. Mater. Sci. 50(6), 2370–2398 (2015). https://doi.org/10.1007/s10853-014-8766-2

L. Zhu, X. Wang, J.P. Hinestroza, M. Naebe, Determination of the porosity in a bifacial fabric using micro-computed tomography and three-dimensional reconstruction. Text. Res. J. 88(11), 1263–1277 (2018). https://doi.org/10.1177/0040517517698987

T. Shinohara, J.Y. Takayama, S. Ohyama, A. Kobayashi, Extraction of yarn positional information from a three-dimensional CT image of textile fabric using yarn tracing with a filament model for structure analysis. Text. Res. J. 80(7), 623–630 (2010). https://doi.org/10.1177/0040517509342320

Q. Lin, Q. Zhu, P. Huang, J. Chen, Z. Ming, J. Yu, A novel hybrid multi-objective immune algorithm with adaptive differential evolution. Comput. Oper. Res. 62, 95–111 (2015). https://doi.org/10.1016/j.cor.2015.04.003

Y.T. Gao, P. Ma, K. Li, J. Xu, Characterization of a 3D auxetic warp-knitted spacer fabric by synchrotron radiation X-ray computed tomography. Fibers Polym. 21(4), 930–933 (2020). https://doi.org/10.1007/s12221-020-9763-5

M. Toda, K. Grabowska, I. Ciesielska-Wróbel, Application of micro-computed tomography (micro-CT) to study unevenness of the structure of yarns. Text. Res. J. 87(3), 351–368 (2017). https://doi.org/10.1177/0040517516629149

H. Zhang, D. Chen, Y. Wan, Fiber migration and twist radial distribution in rotor spun yarns. Text. Res. J. 73(11), 945–948 (2003). https://doi.org/10.1177/004051750307301102

S.Y. Li, B.G. Xu, X.M. Tao, Z.R. Chi, An intelligent computer method for automatic mosaic and segmentation of tracer fiber images for yarn structure analysis. Text. Res. J. 85(7), 733–750 (2015). https://doi.org/10.1177/0040517514551459

B. Xu, Y. Huang, Image analysis for cotton fibers part II: cross-sectional measurements. Text. Res. J. 74(5), 409–416 (2004). https://doi.org/10.1177/004051750407400507

H. Zhang, Y. Xue, S. Wang, Characteristics of rotor spun cotton/spandex composite yarns. Res. J. Text. Appar. 9(3), 45–51 (2005). https://doi.org/10.1108/RJTA-09-03-2005-B007

M. Toda, K.E. Grabowska, Computed microtomography in the analysis of fiber migration in yarn. Autex Res. J. 13(1), 28–32 (2013). https://doi.org/10.2478/v10304-012-0020-x

N. Haleem, X. Liu, C. Hurren, S. Gordon, S.S. Najar, X. Wang, Investigating the cotton ring spun yarn structure using micro computerized tomography and digital image processing techniques. Text. Res. J. 89(15), 3007–3023 (2019). https://doi.org/10.1177/0040517518805387

H.L. Xie, B. Deng, G.H. Du, Y.N. Fu, R.C. Chen, G.Z. Zhou, Y.Q. Ren, Y.D. Wang, Y.L. Xue, G.Y. Peng, Y. H, H. Guo, T.Q. Xiao, Latest advances of X-ray imaging and biomedical applications beamline at SSRF. Nucl. Sci. Tech. (2015). https://doi.org/10.13538/j.1001-8042/nst.26.020102

Acknowledgements

Thanks to the BL13HB line station of Center for Shanghai Synchrotron Radiation Facility, Shanghai Advanced Research Institute, Chinese Academy of Sciences for the experimental support.

Funding

This study was supported in part by grants from the National Natural Science Foundation of China (NSFC), No. 11802317.

Author information

Authors and Affiliations

Contributions

SH did some data analysis and wrote the full manuscript; QL: prepared the samples for CT imaging; MAAN: reviewed the manuscript; YG guided all the experiments and paper writing; KL guide synchrotron radiation CT image processing.

Corresponding authors

Ethics declarations

Conflict of Interest

All authors declare that they have no competing interests.

Ethics Approval and Consent to Participate

The experimental protocol was established, according to the ethical guidelines and was approved by the Human Ethics Committee. Written informed consent was also obtained from individual or guardian participants.

Consent for Publication

Not applicable.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, S., Li, Q., Newton, M.A.A. et al. Research on Cotton Yarn Based on Synchrotron Radiation 3D Micro-CT Imaging. Fibers Polym 25, 543–555 (2024). https://doi.org/10.1007/s12221-023-00463-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00463-7