Abstract

We investigated the tunable mechanical properties of Vectran liquid crystal polymer (LCP) short fiber-reinforced soft composite; we varied the relative foam density and the short fiber loading ratio. The microstructures revealed well-defined pores, matrices, and short fibers. We derived the compressive stress–strain responses and stress relaxations and then performed dynamic mechanical analysis (DMA). To investigate dynamic tunability, the abilities of the soft composites to isolate vibrations from 1 to 300 Hz were assessed. We used the generalized Maxwell model to fit the experimental data and to extract model parameters. We present a simple, versatile, and cost-effective method for the fabrication of LCP short fiber-reinforced soft composites with well-defined and widely tunable mechanical properties. These composites will find applications in many devices.

Similar content being viewed by others

Data availability

All data supporting the findings of this study are included in the article.

References

M.S. Sarfraz, H. Hong, S.S. Kim, Compos. Struct. 266, 113864 (2021)

J. Agarwal, S. Sahoo, S. Mohanty, S.K. Nayak, J. Thermoplast. Compos. Mater. 33, 978 (2019)

R. Yadav, K. Tirumali, X. Wang, M. Naebe, B. Kandasubramanian, Def. Technol. 16, 107 (2020)

W. Wang, H. Rodrigue, H.-I. Kim, M.-W. Han, S.-H. Ahn, Compos. B: Eng. 98, 397 (2016)

D. Zhalmuratova, H.-J. Chung, A.C.S. Appl, Polym. Mater. 2, 1073 (2020)

R. Sen, G. Mullins, Compos. B: Eng. 38, 751 (2007)

D. Yong-Feng, Z. Tong-Wei, Z. Yu, L. Qian-Wen, W. Qiong, Eur. J. Environ. Civ. Eng. 1, 16 (2017)

J. Kaufmann, Procedia Eng. 112, 140 (2015)

M. Matsubara, S. Teramoto, A. Nagatani, S. Kawamura, N. Tsujiuchi, A. Ito, M. Kobayashi, S. Furuta, Exp. Tech. 45, 37 (2020)

D. Norman, R. Robertson, J. Appl. Polym. Sci. 90, 2740 (2003)

W. Ogierman, G. Kokot, Acta Mech. 227, 173 (2015)

Y. Hu, T. Zhao, P. Zhu, Y. Zhang, X. Liang, R. Sun, C.P. Wong, Nano Res. 11, 1938 (2018)

S. Jung, J.H. Kim, J. Kim, S. Choi, J. Lee, I. Park, T. Hyeon, Adv. Mater. 26, 4825 (2014)

Y.Q. Li, W.B. Zhu, X.G. Yu, P. Huang, S.Y. Fu, N. Hu, K. Liao, A.C.S. Appl, Mater. Interfaces. 8, 33189 (2016)

J. Shi, H. Zhang, J. Jackson, A. Shademani, M. Chiao, J. Mater. Chem. B. 4, 7415 (2016)

R. Tao, L. Xi, W. Wu, Y. Li, B. Liao, L. Liu, J. Leng, D. Fang, Compos. Struct. 252, 112663 (2020)

S. Kang, J. Lee, S. Lee, S. Kim, J.-K. Kim, H. Algadi, S. Al-Sayari, D.-E. Kim, D.E. Kim, T. Lee, Adv. Electron. Mater. 2, 1600356 (2016)

A. Koh, J. Sietins, G. Slipher, R. Mrozek, J. Mater. Res. Technol. 33, 2443 (2018)

A. Kaidarova, M.A. Khan, S. Amara, N.R. Geraldi, M.A. Karimi, A. Shamim, R.P. Wilson, C.M. Duarte, J. Kosel, Adv. Eng. Mater. 20, 1800229 (2018)

I. Zubaidah, A. Norfatriah, S.A. Zatul, A. Zuruzi, Fibers 6, 91 (2018)

W. Zhao, T. Li, Y. Li, D.J. O’Brien, M. Terrones, B. Wei, J. Suhr, X.L. Lu, J. Mater. 4, 157 (2018)

B.F. Donadon, N.T. Mascia, R. Vilela, L.M. Trautwein, Eng. Struct. 202, 109818 (2020)

S. Gantenbein, C. Mascolo, C. Houriet, R. Zboray, A. Neels, K. Masania, A.R. Studart, Adv. Funct. Mater 31, 2104574 (2021)

Y. Chen, S. Li, G. Fu, J. Eng. Fibers Fabr. 16, 1 (2021)

A. Komorek, R. Szczepaniak, P. Przybylek, A. Krzyzak, J.A. Godzimirski, M.R. Roskowicz, D. Seremak, Compos. Struct. 256, 113045 (2021)

D. Jalocha, A. Constantinescu, R. Neviere, Int. J. Solids Struct. 67–68, 169 (2015)

X. Zhao, T. Wang, Y. Li, L. Huang, S. Handschuh-Wang, Polymers (Basel) 11, 948 (2019)

D. Zhu, S. Handschuh-Wang, X. Zhou, J. Mater. Chem. A. 5, 16467 (2017)

J. Fan, A. Chen, Polymers (Basel) 11, 467 (2019)

I.D. Johnston, D.K. McCluskey, C.K.L. Tan, M.C. Tracey, J. Micromech. Microeng. 24, 035017 (2014)

J. Lei, M. Xu, T. Liu, Y. Xuan, H. Sun, Z. Wei, AIP Adv. 10, 075315 (2020)

L. Andena, F. Caimmi, L. Leonardi, M. Nacucchi, F. De Pascalis, J. Cell. Plast. 55, 49 (2018)

J.V. Mane, S. Chandra, S. Sharma, H. Ali, V.M. Chavan, B.S. Manjunath, R.J. Patel, Procedia Eng. 173, 726 (2017)

T. Hana, T. Janda, J. Schmidt, A. Zemanova, M. Sejnoha, M. Eliasova, M. Vokac, Materials (Basel) 12, 2241 (2019)

Acknowledgements

This work was supported by the grant funded by Ministry of Trade, Industry and Energy (MOTIE, Korea) and the Korea Evaluation Institute of Industrial Technology (KEIT) (Grant No. 20006388, and No. 20017462); and the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. NRF-2020R1A2C4001731).

Author information

Authors and Affiliations

Contributions

G-YL and S-HL conceptualized this work. G-YL, S-HL, and G-SL designed the materials, specimens, and the experiments. G-SL and G-YL conducted the experiments. G-YL and G-SL analyzed the data and wrote the paper, and all authors provided feedback. G-YL supervised the project.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Appendix

Appendix

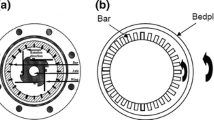

See Figure 18.

In Fig. 18a, the normal stress within the soft composite is [28]:

where ε(t) is the strain, t is the time, \(E_{R} \left( t \right) = E_{V} e^{{ - \frac{t}{{\tau_{V} }}}}\) is the relaxation kernel, τV = EV/ηV is the relaxation time, and τ is an integral variable. Then, force Fσ(t) in Fig. 18b is:

where A is the area of the soft composite.

Because \(\varepsilon \left( t \right) = \frac{{x_{1} \left( t \right) - x_{2} \left( t \right)}}{L}\), where x1(t) and x2(t) are the displacements of the base (m1) and the upper (m2) mass, respectively, and L is the initial thickness of the soft composite, we obtain:

By introducing a spring constant \(K_{\infty } = \frac{{E_{\infty } A}}{L}\) and the relaxation stiffness \(K_{V} = \frac{{E_{V} A}}{L}\), we obtain:

where \(K_{R} \left( t \right) = \frac{{E_{V} A}}{L}e^{{ - \frac{t}{{\tau_{V} }}}} = K_{V} e^{{ - \frac{t}{{\tau_{V} }}}}\) is the relaxation kernel [28].

The Fourier transform of Eq. (4) yields:

where ω is the angular frequency, \(j = \sqrt { - 1}\) is the imaginary unit, X1(ω) and X2(ω) are the Fourier transforms of x1(t) and x2(t), respectively, and jωKR(ω) is:

By introducing the complex stiffness \(K^{*} \left( \omega \right) = K_{\infty } + K^{\prime}\left( \omega \right) + jK^{\prime\prime}\left( \omega \right)\), we obtain:

where \(K^{\prime}\left( \omega \right) = \frac{{K_{V} \omega^{2} \tau_{V}^{2} }}{{1 + \omega^{2} \tau_{V}^{2} }}\) is the storage stiffness, and \(K^{\prime\prime}\left( \omega \right) = \frac{{K_{V} \omega \tau_{V} }}{{1 + \omega^{2} \tau_{V}^{2} }}\) is the loss stiffness.

The equations of motion of the vibration system of Fig. 18(b) are:

where Fe(t) denotes the excitation force.

The Fourier transforms of Eq. (8) yield:

By inserting Eq. (7) into (9) and solving for X1(ω) and X2(ω), we obtain:

where \(\Delta \left( {\omega^{2} } \right) = \left[ {K^{*} \left( \omega \right) - m_{1} \omega^{2} } \right]\left[ {K^{*} \left( \omega \right) - m_{2} \omega^{2} } \right] - K^{*} \left( \omega \right)^{2}\).

The transmissibility is then \(\frac{{X_{2} \left( \omega \right)}}{{X_{1} \left( \omega \right)}} = \frac{{K^{*} \left( \omega \right)}}{{K^{*} \left( \omega \right) - m_{2} \omega^{2} }}\).

Using \(K^{*} \left( \omega \right) = K_{\infty } + \frac{{K_{V} \omega^{2} \tau_{V}^{2} }}{{1 + \omega^{2} \tau_{V}^{2} }} + j\frac{{K_{V} \omega \tau_{V} }}{{1 + \omega^{2} \tau_{V}^{2} }}\), the magnitude \(\left| {\frac{{X_{2} \left( \omega \right)}}{{X_{1} \left( \omega \right)}}} \right|\) then becomes:

Finally using \(K_{\infty } = \frac{{E_{\infty } A}}{L}\) and \(K_{V} = \frac{{E_{V} A}}{L}\), \(\left| {\frac{{X_{2} \left( \omega \right)}}{{X_{1} \left( \omega \right)}}} \right|\) is obtained in terms of E∞, EV, and τV as:

Equation (12) was used to fit the transmissibility data of Fig. 15 by deriving the fitting coefficients E∞, EV, and τV of Fig. 16.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, GS., Lee, SH. & Lee, GY. Tunable Mechanical Properties of Vectran Liquid Crystal Polymer (LCP) Short Fiber-Reinforced Soft Composite. Fibers Polym 24, 207–220 (2023). https://doi.org/10.1007/s12221-023-00095-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-023-00095-x