Abstract

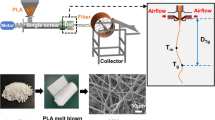

Melt-blown nonwovens are widely used for their fine fibers and porous structure, but poor toughness and limited elongation prevent further application due to the characteristics of Polypropylene (PP), which is the main raw material of melt-blown nonwovens. In this work, ethylene-vinyl acetate copolymer (EVA) was added to PP in different proportions by using the blending method to improve the toughness and elongation of melt-blown nonwovens. Although the morphology of the blends showed a poor compatibility between PP and EVA, the thermal stability and rheological properties of the blends were excellent indicating a good spinnability from the consequent melt-blowing process. The fiber diameter of the nonwovens first increased then decreased with an increase of EVA content in the range of 5 % to 30 %. With the addition of EVA, the tensile strength and tensile modulus of nonwovens decreased and the elongation increased.

Similar content being viewed by others

References

R. L. Shambaugh, Ind. Eng. Chem. Res., 27, 2363 (1988).

S. Sinha-Ray, A. L. Yarin, and B. Pourdeyhimi, Polymer, 55, 4241 (2014).

M. A. Hassan, B. Y. Yeom, A. Wilkie, B. Pourdeyhimi, and S. A. Khan, J. Membr. Sci., 427, 336 (2013).

A. Alassod and G. B. Xu, J. Text. Inst., https://doi.org/10.1080/00405000.2020.1821983 (2020).

B. C. Shiu, J. C. Jhang, T. T. Li, H. K. Peng, L. W. Wu, C. W. Lou, and J. H. Lin, J. Ind. Text., https://doi.org/10.1177/1528083720930378 (2020).

A. A. Guliakova, M. F. Galikhanov, L. R. Galeeva, S. V. Gilfanova, and P. Fang, IEEE T. Dielect. El. In., 27, 1656 (2020).

J. D. Tucker, S. Lee, and R. L. Einsporn, Polym. Eng. Sci., 40, 2577 (2000).

D. Kakkar and S. N. Maiti, J. Appl. Polym. Sci., 123, 1905 (2011).

M. Öksüz and M. Eroğlu, J. Appl. Polym. Sci., 98, 1445 (2005).

S. H. Jafari and A. K. Gupta, J. Appl. Polym. Sci., 78, 962 (2000).

R. Nikoomanesh, N. Naderpour, and V. Goodarzi, Polym. Compos., 40, 1964 (2019).

S. Sava and A. Y. Al-Obaidi, Tribol. T., 61, 754 (2018).

H. Li, H. Huang, X. H. Meng, and Y. C. Zeng, J. Polym. Sci., 56, 970 (2018).

M. N. Peng, H. Y. Jia, L. Jiang, Y. F. Zhou, and J. W. Ma, J. Text. Inst., 110, 468 (2019).

Y. F. Zhou, L. Jiang, H. Y. Jia, X. L. Xing, Z. H. Sun, S. J. Chen, J. W. Ma, and S. Jerrams, Fiber. Polym., 20, 1200 (2019).

P. Svoboda, R. Theravalappil, D. Svobodova, P. Mokrejs, K. Kolomaznik, K. Mori, T. Ougizawa, and T. Inoue, Polym. Test., 29, 742 (2010).

X. L. Yan, X. H. Xu, T. B. Zhu, C. H. Zhang, N. Song, and L. Zhu, Mater. Sci. Eng., 476, 120 (2008).

T. McNally, P. McShane, G. M. Nally, W. R. Murphy, M. Cook, and A. Miller, Polymer, 43, 3785 (2002).

G. Y. Przybytniak, K. Mirkowski, A. Rafalski, A. Nowicki, and E. Kornacka, Radiat. Phys. Chem., 76, 1312 (2007).

T. Jeevananda and Siddaramaiah, Thermochim. Acta, 376, 51 (2001).

B. Wang and J. Zhao, J. Appl. Polym. Sci, 90, 1970 (2003).

E. Ramírez Vargas, B. Margarita Huerta Martínez, F. Javier Medellín Rodríguez, and S. Sánchez Valdes, J. Appl. Polym. Sci., 112, 2290 (2009).

M. R. Aghjeh, H. A. Khonakdar, and S. H. Jafari, Compos. Pt. B-Eng., 79, 74 (2015).

V. Goodarzi, S. Hassan Jafari, H. Ali Khonakdar, B. Ghalei, and M. Mortazavi, J. Membr. Sci., 445, 76 (2013).

V. Goodarzi, S. H. Jafari, H. A. Khonakdar, and J. Seyfi, J. Polym. Res., 18, 1829 (2011).

H. Hamadache, H. Djidjelli, A. Boukerrou, M. Kaci, J.-R. José Antonio, and J. M. Martín-Martínez, Polym. Compos., 40, 3242 (2019).

H. Z. Liu, T. X. Xie, Y. Zhang, Y. C. Ou, and G. S. Yang, J. Polym. Sci. Pt. B-Polym. Phys., 44, 1050 (2006).

S. Thomas and A. George, Eur. Polym. J., 28, 1451 (1992).

A. K. Gupta, B. K. Ratnam, and K. R. Srinivasan, J. Appl. Polym. Sci., 46, 281 (1992).

I. Soltani and C. W. Macosko, Polymer, 145, 21 (2018).

J. F. Carley and S. C. Crossan, Polym. Eng. Sci., 21, 249 (1981).

Y. M. Song, Y. Y. Wang, H. Li, Q. L. Zong, and A. L. Xu, Materials, 12, 106 (2019).

H. Panigrahi, P. R. Sreenath, A. K. Bhowmick, and K. D. Kumar, Polymer, 183, 121866 (2019).

D. H. Tan, C. Zhou, C. J. Ellison, S. Kumar, C. W. Macosko, and F. S. Bates, J. Non-Newton. Fluid., 165, 892 (2010).

Y. J. Zhang and X. Y. Jin, J. Wood Sci., 64, 256 (2018).

E. Ramirez-Vargas, D. Navarro-Rodriguez, F. J. Medellin-Rodriguez, B. M. Huerta-Martinez, and J. S. Lin, Polym. Eng. Sci., 40, 2241 (2000).

Acknowledgments

The authors would like to acknowledge the financial assistance provided by the Key R & D project of Shandong Province (No 2018GGX108003).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chang, L., Xing, X., Zhou, Y. et al. Effects of EVA Content on Properties of PP/EVA Blends and Melt-blown Nonwovens. Fibers Polym 23, 882–890 (2022). https://doi.org/10.1007/s12221-022-4212-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-022-4212-2