Abstract

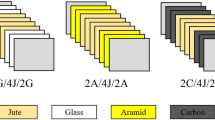

Among the drawbacks that the composites entirely reinforced with carbon fibers have, low strain-to-failure and catastrophic failure behaviour are the most undesirable ones. Nonetheless, in many industries for example in automobile industries, the necessity of light-weight structures with a balanced cost is unquestionable. Hybridization of glass fibers with carbon fibers could be an effective way to improve the strain-to-failure of composites entirely reinforced carbon fibers and therefore, a balance between the stiffness and toughness could be improved without excessive cost. In this paper, for automobile applications it is proposed to selectively incorporate the glass and carbon fibers through intra-layer hybridization technique. It is also proposed to mix the fibers as intimately as possible. This paper investigates the influences of hybrid ratio and laminate geometry on tensile mechanical properties both computationally and experimentally- and they have been found to have significant influences on tensile properties and hence should be treated as most crucial parameters. The brittle and catastrophic failure of plain carbon composite was avoided through intra-tow hybridization with higher dispersion. Damage mechanism has been explained and SEM observations were carried out for morphology analysis. Vacuum assisted resin infusion process is also recommended to attain high quality of impregnation.

Similar content being viewed by others

References

N. Oya and H. Hamada, Sci. Eng. Compos. Mater., 5, 105 (1996).

C. Dong and I. J. Davies, J. Mater. Des. Appl., 227, 308 (2013).

S. M. B. Sudarisman and I. J. Davies, Proc. Intl. Confer. Mater. Metallurgical Technol., pp.125–128, 2009.

N. Oya and D. J. Johnson, Carbon, 39, 635 (2001).

I. J. Davies, Adv. Mater. Res., 41, 357 (2008).

M. Shioya and M. Nakatani, Compos. Sci. Technol., 60, 219 (2000).

P. Manders and M. Bader, J. Mater. Sci., 16, 2233 (1981).

A. Bunsell and B. Harris, Composites, 5, 157 (1974).

C. Zweben, J. Mater. Sci., 12, 1325 (1977).

G. Marom, S. Fischer, F. R. Tuler, and H. D. Wagner, J. Mater. Sci., 13, 1419 (1978).

D. R. Cramer and D. F. Taggart, Proc. 19th Inter. Battery. Hybrid. Fuel Cell Electric Vehicle Symp. Exhibit., 2002.

P. Beardmore and C. F. Johnson, Compos. Sci. Technol., 26, 251 (1986).

G. Thilagavathi, E. Pradeep, T. Kannaian, and L. Sasikala, J. Ind. Text., 39, 267 (2010).

S. Das, Oak Ridge National Laboratory, Oak Ridge, TN, 2001.

H. A. Al-Qureshi, J. Mater. Process. Technol., 118, 58 (2001).

R. Hosseinzadeh, M. M. Shokrieh, and L. B. Lessard, Compos. Struct., 68, 419 (2005).

N. Tucker and K. Lindsey, An Introduction to Automotive Composites. iSmithers Rapra Publishing, 2002.

A. Jacob, Reinf. Plast., 45, 28 (2001).

Z. Z. S. Huanchun, Beijing University of Aeronautics and Astronautics, Chap 4, 1988.

A. K. Kaw, Mecha. Compos. Mater., 2nd ed., Tampa: CRC press, Taylor & Francis Group, 2005.

M. Grujicic, B. Pandurangan, K. L. Koudela, and B. A. Cheeseman, Appl. Surf. Sci., 253, 730 (2006).

S. Y. Fu, Y. W. Mai, B. Lauke, and C. Y. Yue, Mater. Sci. Eng. A-Struct. Mater. Prop., 323, 326 (2002).

J. W. Giancaspro, C. G. Papakonstantinou, and P. Balaguru, J. Eng. Mater. Technol., 132, 021005 (2010).

S. F. Hwang and C. P. Mao, Compos. Sci. Technol., 61, 1513 (2001).

G. Kretsis, Composites, 18, 13 (1987).

K. S. Pandya, C. Veerraju, and N. Naik, Mater. Des., 32, 4094 (2011).

Y. Zhang, Y. Li, H. Ma, and T. Yu, Compos. Sci. Technol., 88, 172 (2013).

P. Ren, Z. Zhang, L. Xie, F. Ren, Y. Jin, Y. Di, and C. Fang, Polym. Compos., 31, 2129 (2010).

C. Dong, J. Duong, and I. J. Davies, Polym. Compos., 33, 773 (2012).

C. Dong and I. J. Davies, Mater. Des., 37, 450 (2012).

M. Sayer, N. B. Bektas, and O. Sayman, Compos. Struct., 1256 (2010).

Z. S. Wu, X. Wang, K. Iwashita, T. Sasaki, and Y. Hamaguchi, Compos. Pt. B-Eng., 41, 396 (2010).

A. Goren and C. Atas, Archiv. Mater. Sci. Eng., 34, 117 (2008).

C. Dong, H. A. Ranaweera-Jayawardena, and I. J. Davies, Compos. Pt. B-Eng., 43, 573 (2012).

P. N. B. Reis, J. A. M. Ferreira, F. V. Antunes, and J. D. M. Costa, Compos. Pt. A-Appl. Sci. Manuf., 38, 1612 (2007).

Z. Hashin, J. Appl. Mecha., 47, 329 (1980).

S. Chan, Z. Fawaz, K. Behdinan, and R. Amid, Compos. Struct., 77, 466 (2007).

Z. Hashin and A. Rotem, J. Compos. Mater., 7, 448 (1973).

M. L. Costa, S. F. M. D. Almeida, and M. C. Rezende, Compos. Sci. Technol., 61, 2101 (2001).

J. M. Tang, W. I. Lee, and G. S. Springer, J. Compos. Mater., 21, 421 (1987).

L. Liu, B. M. Zhang, D. F. Wang, and Z. J. Wu, Compos. Struct., 73, 303 (2006).

S. R. Ghiorse, Sampe Quarterly, 1, 54 (1993).

J. Zhang, K. Chaisombat, S. He, and C. H. Wang, Mater. Des., 36, 75 (2012).

H. Ikbal, Q. Wang, A. Azzam, and W. Li, Fiber. Polym., 17, 117 (2016).

G. Czél and M. Wisnom, Compos. Pt. A-Appl. Sci. Manuf., 52, 23 (2013).

Y. You, Y. Park, H. Y. Kim, and J. S. Park, Compos. Struct., 80, 117 (2007).

H. Diao, A. Bismarck, P. Robinson, and M. R. Wisnom, Proceedings of ECCM, 2012.

I. Taketa, PhD. Thesis, Leuven: KU Leuven, 2011.

P. K. Mallick, Fiber-reinforced Composites: Materials, Manufacturing, and Design, 2nd ed., pp.243–244, CRC Press, 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ikbal, H., Wang, Q., Azzam, A. et al. GF/CF hybrid laminates made through intra-tow hybridization for automobile applications. Fibers Polym 17, 1505–1521 (2016). https://doi.org/10.1007/s12221-016-5953-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-016-5953-6