Abstract

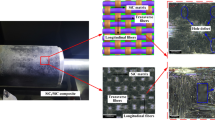

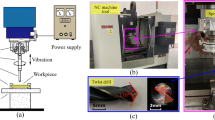

AISI 420 is primarily used for optic molds manufactured through ultraprecision machining with single-crystal diamond tools. Tool wear rapidly occurs due to the diffusion of diamond and iron atoms when cutting ferrous metals with diamond tools. In the machining of optic molds, the diamond tool is uniformly replaced, regardless of the tool status after use for some time due to the difficulty in predicting tool life. This practice results in the wastage of expensive single-crystal diamond tools and reduces productivity. This study addressed the aforementioned issue by developing a tool-life model through theoretical analysis of the effective contact ratio between the tool and the workpiece and a cutting experiment with high-frequency ultrasonic vibration. In addition, the effectiveness of ultrasonic vibration cutting on the suppression of diamond tool wear was demonstrated by measuring tool wear after the cutting experiments.

Similar content being viewed by others

References

S. J. Zhang, S. To and G. Q. Zhang, Diamond tool wear in ultra-precision machining, The International Journal of Advanced Manufacturing Technology, 88 (2017) 613–641.

X. Q. Zhang, Y. Meng, Z. Yang, Z. Zhang, M. Ren and L. Zhu, Ultraviolet-ozone assisted ultrasonic vibration cutting for extending diamond tool life, Journal of Materials Processing Technology, 304 (2022) 117560.

T. Moriwaki, Machinability of copper in ultra-precision micro diamond cutting, CIRP Annals, 38(1) (1989) 115–118.

A. Pramanik, K. S. Neo, M. Rahman, X. P. Li, M. Sawa and Y. Maeda, Cutting performance of diamond tools during ultra-precision turning of electroless-nickel plated die materials, Journal of Materials Processing Technology, 140 (2003) 308–313.

J. H. Wang, S. Dong, H. X. Wang, M. J. Chen, W. J. Zong and L. J. Zhang, Forecasting of surface roughness and cutting force in single point diamond turning for KDP crystal, Key Engineering Materials, 339 (2007) 78–83.

Z. Y. Wang, L. H. Dong, D. S. Wang and Y. H. Dong, Study of HPHT single crystal diamond as precision cutting tool material, Precision Engineering, 36 (2012) 162–167.

G. Jiang, Z. Jianguo, P. Yanan, K. Renke, N. Yoshiharu, S. Paul, Y. Xiaobin, W. Baorui and G. Dongming, A critical review on the chemical wear and wear suppression of diamond tools in diamond cutting of ferrous metals, International Journal of Extreme Manufacturing, 2(1) (2020) 12001.

M. A. Kanter, Diffusion of carbon atoms in natural graphite crystals, Physical Review Journals Archive, 107 (655) (1957).

L. Zou and M. Zhou, Diffusion wear mechanism of single crystal diamond tool in machining die steels, Key Engineering Materials, 625 (2014) 155–160.

L. Zou and M. Zhou, Experimental investigation and numerical simulation on interfacial carbon diffusion of diamond tool and ferrous metals, Journal of Wuhan University of Technology-Mater, 31 (2016) 307–314.

L. Zou and M. Zhou, Diffusion wear mechanism of single crystal diamond tool in machining die steels, Key Engineering Materials, 625 (2015) 155–160.

L. Zou, J. Yin, Y. Huang and M. Zhou, Essential causes for tool wear of single crystal diamond in ultra-precision cutting of ferrous metals, Diamond and Related Materials, 86 (2018) 29–40.

M. Xiao, Q. M. Wang, K. Sato, S. Karube, T. Soutome and H. Xua, The effect of tool geometry on regenerative instability in ultrasonic vibration cutting, International Journal of Machine Tools and Manufacture, 46 (2006) 492–499.

D. E. Brehl and T. A. Dow, Review of vibration-assisted machining, Precision Engineering, 32 (2008) 153–172.

T. Moriwaki and E. Shamoto, Ultraprecision diamond turning of stainless steel by applying ultrasonic vibration, CIRP Annals, 40 (1991) 559–562.

E. Brinksmeier and R. Gläbe, Advances in precision machining of steel, CIRP Annals, 50(1) (2001) 385–388.

Y. Zhang, Z. Zhou, Y. Lv, J. Wang, L. Shao and A. Iqbal, Wear behavior of natural diamond tool in cutting tungsten-based alloy, The International Journal of Advanced Manufacturing Technology, 69 (2013) 329–335.

R. Gaidys, O. Dambon, V. Ostasevicius and C. Dicke, Ultrasonic tooling system design and development for single point diamond turning (SPDT) of ferrous metals, The International Journal of Advanced Manufacturing Technology, 93 (2017) 2841–2854.

C. Zhang, C. Cheung, B. Bulla and C. Zhao, An Investigation of the high-frequency ultrasonic vibration-assisted cutting of steel optic moulds, Micromachines, 12(4) (2021) 460.

P. W. Marksberrya and I. S. Jawahir, A comprehensive tool-wear/tool-life performance model in the evaluation of NDM (near dry machining) for sustainable manufacturing, International Journal of Machine Tools and Manufacture, 48 (2008) 878–886.

Y. Xu, Z. Wan, P. Zou, W. Huang and G. Zhang, Experimental study on cutting force in ultrasonic vibration-assited turning of 304 austenitic stainless steel, Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 235(3) (2021) 494–513.

Y. He, Z. Zhou, P. Zou, X. Gao and K. F. Ehmann Study on ultrasonic vibration-assisted thread turning of Inconel 718, Advanced in Mechanical Engineering, 11 (10) (2019).

Acknowledgments

This work was supported by the National Research Foundation of Korea grant funded by the Korean government (MSIT) (RS-2023-00278890).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Il Chae Yoon is a Ph.D student at Mechanical Engineering, Yeungnam University. He received his B.S. and M.S. from Yeungnam University, South Korea. His research interests are ultraprecision machining, ultrasonic vibration-assisted machining, and cutting tool performance.

Ik Soo Kang is a Principal Researcher at Daegu Mechatronics & Materials Institute. He received his Ph.D. degree from the School of Mechanical Engineering, Pusan National University, South Korea. His research interests include artificial intelligence application to machining and cutting tools.

Ye In Kwak is a Ph.D. student at Mechanical Engineering, Yeungnam University. He received his B.S. and M.S. from Yeungnam University, South Korea. Mr. Kwak is mainly engaged in research related to surface texturing of the machining process.

Rendi Kurniawan is currently an Assistant Professor at Yeungnam University, South Korea. He received his B.Eng. degree from Universitas Indonesia, Indonesia. His received his M.S. and Ph.D. degrees from Yeungnam University, Korea. His research interests are surface texturing and elliptical vibration texturing.

Tae Jo Ko is a Professor of Mechanical Engineering at Youngman University, South Korea. He received his B.S. and M.S. from the Pusan National University, South Korea and Ph.D. from POSTECH, Korea. His research interests include machine tools, metal cutting and nontraditional machining, surface texturing using metal cutting, grinding, and bio-machining.

Rights and permissions

About this article

Cite this article

Yoon, I.C., Kang, I.S., Kwak, Y.I. et al. Investigation of tool life in the single-crystal diamond turning of AISI 420 using high-frequency ultrasonic vibration. J Mech Sci Technol 38, 2519–2526 (2024). https://doi.org/10.1007/s12206-024-0430-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-024-0430-4