Abstract

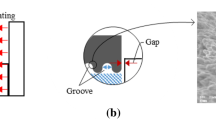

We present a simple and cost-effective method to produce superhydrophobic surfaces in thermoplastic polymer substrates, which contain hierarchical micro/nano structures that resemble lotus leaves. The method involved the fabrication of an Al stamp through the sequential application of laser ablation and anodization to create micro- and nano-structures, respectively. The fabricated patterns on the Al stamp were replicated on the thermoplastic Cyclic olefin copolymer (COC) film surfaces through a hot embossing technique. Static water contact angles were measured to evaluate the hydrophobicity of the patterned COC surfaces. The static water contact angle on the micro/ nano hierarchical structured COC surface was measured to be 162.3° on average. The hot embossing process was repeated 31 times with a nano-structured Al stamp, and the replicated COC surfaces showed consistent water contact angles.

Similar content being viewed by others

References

Z. Burton and B. Bhushan, Surface characterization and adhesion and friction properties of hydrophobic leaf surfaces, Ultramicroscopy, 106 (2006) 709–719.

Y. Y. Yan, N. Gao and W. Barthlott, Mimicking natural superhydrophobic surfaces and grasping the wetting process: A review on recent progress in preparing superhydrophobic surfaces, Advances in Colloid and Interface Science, 169 (2) (2011) 80–105.

B. Lee, J. Seong, H. Park and H. Choi, Flow structures around a butterfly-shaped low-aspect-ratio wing, Journal of Mechanical Science and Technology, 28 (7) (2014) 2669–2675.

M. Nosonovsky and B. Bhushan, Biomimetic superhydrophobic surfaces: multiscale approach, Nano Letters, 7 (9) (2007) 2633–2637.

Y. Lee, S. H. Park, K. B. Kim, J. K. Lee and M. K. Kim, Fabrication of hierarchical structures on a polymer surface to mimic natural superhydrophobic surfaces, Advanced Materials, 19 (17) (2007) 2330–2335.

C. W. Berendsen, M. Škeren, D. Najdek and F. Cerný, Superhydrophobic surface structures in thermoplastic polymers by interference lithography and thermal imprinting, Applied Surface Science, 255 (23) (2009) 9305–9310.

I. Saarikoski, M. Suvanto and T. A. Pakkanen, Modification of polycarbonate surface properties by nano-, micro-, and hierarchical micro–nanostructuring. Applied Surface Science, 255 (22) (2009) 9000–9005.

S. W. Ryu, S. Choo, H. J. Choi, C. H. Kim and H. Lee, Replication of rose petal surfaces using a nickel electroforming process and UV nanoimprint lithography, Applied Surface Science, 322 (2014) 57–63.

E. Lepore and N. Pugno, Superhydrophobic polystyrene by direct copy of a lotus leaf, BioNanoscience, 1 (4) (2011) 136–143.

J. Noh, J. H. Lee, S. Na, H. Lim and D. H. Jung, Fabrication of hierarchically micro-and nano-structured mold surfaces using laser ablation for mass production of superhydrophobic surfaces, Japanese Journal of Applied Physics, 49 (10R) (2010) 106502.

P. H. Wu, C. W. Cheng, C. P. Chang, T. M. Wu and J. K. Wang, Fabrication of large-area hydrophobic surfaces with femtosecond-laser-structured molds, Journal of Micromechanics and Microengineering, 21 (11) (2011) 115032.

D. Chu, A. Nemoto and H. Ito, Biomimetic superhydrophobic polymer surfaces by replication of hierarchical structures fabricated using precision tooling machine and anodized aluminum oxidation, Microsystem Technologies, 21 (1) (2015) 123–130.

E. Puukilainen, T. Rasilainen, M. Suvanto and T. A. Pakkanen, Superhydrophobic polyolefin surfaces: controlled micro-and nanostructures, Langmuir, 23 (13) (2007) 7263–7268.

G. D. Sulka, Highly ordered anodic porous alumina formation by self-organized anodizing, Nanostructured materials in electrochemistry, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany (2008) 1–116.

L. Zaraska, G. D. Sulka, J. Szeremeta and M. Jaskula, Porous anodic alumina formed by anodization of aluminum alloy (AA1050) and high purity aluminum, Electrochimica Acta, 55 (14) (2010) 4377–4386.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Sangho Park

Chae-Hee Lim received his B.S. in Mechanical Design Engineering from Korea Polytechnic University, Korea, in 2015. He was a formely graduate student at the Department of Advanced Convergence Technology. His research interests are in the area of design of functional devices based on micro/nanoreplication technologies.

Wook-Bae Kim received his Ph.D. in Mechanical Engineering from Yonsei University, Korea, in 2003. He then worked as Head Researcher at Samsung Electronics. He is currently an Associate Professor at the Department of Mechanical Design Engineering at Korea Polytechnic University in Siheung, Korea. His research interests include micro/nano-fabrication, plastic processing, and precision surface finishing.

Rights and permissions

About this article

Cite this article

Lim, CH., Han, SY., Eo, JD. et al. Superhydrophobic hierarchical structures produced through novel low-cost stamp fabrication and hot embossing of thermoplastic film. J Mech Sci Technol 29, 5107–5111 (2015). https://doi.org/10.1007/s12206-015-1108-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-015-1108-8