Abstract

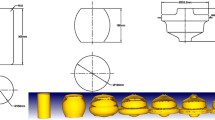

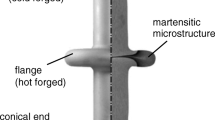

In this research, the finite element method is utilized to predict the temperature distributions in a cold-forging process for a cambolt. The cambolt is mainly used as a part of a suspension system of a vehicle. The cambolt has an off-centered lobe that manipulates the vertical position of the knuckle and wheel to a slight degree. The cambolt requires certain mechanical properties, such as strength and endurance limits. Moreover, temperature is also an important factor to realize mass production and improve efficiency. However, direct measurement of temperature in a forging process is infeasible with existing technology; therefore, there is a critical need for a new technique. Accordingly, in this study, a thermo-coupled finite element method is developed for predicting the temperature distribution. The rate of energy conversion to heat for the workpiece material is determined, and the temperature distribution is analyzed throughout the forging process for a cambolt. The temperatures associated with different punch speeds are also studied, as well as the relationships between load, temperature, and punch speed. Experimental verification of the technique is presented.

Similar content being viewed by others

References

J. T. Oden and D. R. Bhandari et al., A new approach to the finite element formulated and solution of a class of problem in coupled thermo-elasto-viscoplasticticty of crystalline solid, Journal of Nuclear Engineering Design, 24 (1973).

N. Rebelo and S. Kobayashi, A coupled analysis of viscoplastic deformation and heat transfer, Journal of Mechanical Science, 22 (1980) 707–718.

T. Altan and R. J. Fiorentino, Prediction of load and stress in closed die forging, Trans. ASME Journal of Eng., For Ind., Series B, (1971) 477–484.

B. S. Zhao et al., FEM numerical simulation technology of metal plasticity forming process, Journal of Hot Working Technology, 39(7) 7 (2010).

T. Altan, H. J. Henning and A. M. Sabroff, Forging loads and stresses in closed-die forging: part one, Battelle Memorial Institute, Contract DAAG 4-68-c-0111 (1968).

L. Yin et al., Simulation of temperature field during crankshaft forging process”, Journal of Hot Working Technology, 38(11) (2009).

Y. G. Wei, Coupled thermo-mechanical FE analysis of closed-die cold forging, Journal of Forging Technology, 2 (2003) 13–15.

W. H. Zhang et al., Multistep forging forming and temperature field couple analysis of high strength bolt, Journal of Aeronautical Manufacturing Technology, 6 (2004) 77–80.

L. G. Fu et al., Die-forging of TA15 alloy high-strength bolt, Chinese Journal of Nonferrous Metals, 20(1) (2010) 718–721.

K. W. Kim et al., Finite element analysis for multi-stage forging process design of bolt with nonaxisymmetric washer camber, Journal of the Korean Society of Marine Engineering, 32(4) (2008) 585–595.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Haedo Jeong

Dongbum Kim is in doctoral course in Department of Mechanical Engineering at Chungbuk national university. He received his bachelor’s degree and master’s degree in Chungbuk national university at 2009 and 2011.

Sungwook Kim received his bachelor’s degree in Mechanical Engineering from Yanbian national university. He received his master degree in Mechanical Engineering from Yanbian national university 2013. Now he is a engineer in hyundaigroup.

Inchul Song is excutive director in Sunil dyfas. He is now in Master & doctorate course in mechanical engineering Chungbuk national university. He received his bachelor’s degree in Mechanical Engineering from Sungkyunkwan university.

Byungcheol Jeon is a advanced research team general manager in Sunil dyfas. He received his doctoral degree in Mechanical Engineering from Inha national university at 2001.

Inhwan Lee Cho is a professor in the Department of Mechanical Engineering at Chungbuk national university, South Korea. He received his doctoral degree in Mechanical Engineering from Pohang university of science at 2003.

Haeyong Cho is a professor in the Department of Mechanical Engineering at Chungbuk national university, South Korea. He received his doctoral degree in Mechanical Engineering from Pusan national university at 1991.

Rights and permissions

About this article

Cite this article

Kim, D., Kim, S., Song, I. et al. Finite element analysis for temperature distributions in a cold forging. J Mech Sci Technol 27, 2979–2984 (2013). https://doi.org/10.1007/s12206-013-0813-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-013-0813-4