Abstract

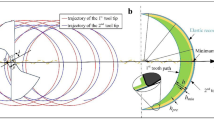

The location and the size of a geometrically defected region in the side wall of a corner, which is generated during the flat end-milling process, are investigated through experiments and geometrical analysis. A corner with inner and outer surfaces is assumed to be made up of one arc-surface patch and two flat-surface patches. Based on the previous findings that the change of material removal per tooth affects the geometry of the end-milled side wall, it is expected that the geometrically defected regions are located around the corner when the tool is approaching and leaving the arc surface. In this respect, analytic models are proposed to predict the location and the size of a geometrically defected region, which are then validated via comparison with the experimental results.

Similar content being viewed by others

References

E. Budak and Y. Altintas, Peripheral milling conditions for improved dimensional accuracy, Int. J. Mach. Tools Manu., 34(7) (1994) 907–918.

J. G. Choi and M. Y. Yang, In-process prediction of the surface error using an identification of cutting depths in end milling operation by simulating surface, J. of KSPE, 15(2) (1998) 114–123.

S. L. Ko, S. K. Lee and S. M. Bae, Study on the design of end mill geometry, J. of KSPE, 18(8) (2001) 24–30.

S. K. Lee, and S. L. Ko, Analysis on the precision machining in end milling operation by simulating surface generation, J. of KSPE, 16(4) (1999) 229–236.

S. H. Ryu, D. K. Choi and C. N. Chu, Optimal cutting condition in side wall milling considering form accuracy, J. of KSPE, 20(10) (2003) 31–39.

J. Tlusty, S. Smith and C. Zamudia, New NC routines for quality in milling, Annals of CIRP, 39(1) (1990) 517–521.

J. H. Yoon, M. S. Cheong and H. C. Lee, A study on transition of dimension error and surface precision in high speed machining of Al-alloy, J. of KSMTE, 9(3) (2003) 96–102.

H. D. Cho and M. Y. Yang, A study on the prediction of tool deflection and precision machining in ball end milling process, KSME Journal, 16(9) (1992) 1669–1680.

Y. H. Kim and S. L. Ko, Improvement of the accuracy in cornering cut using end mill, KSME Journal, Vol. 25/A(3) (2001) 399–407.

T. I. Seo and M. W. Cho, Tool trajectory generation based on tool deflection effects in flat-end milling process (I) -tool path compensation strategy, KSME International Journal, 13( 10) (1999) 738–751.

T. I. Seo and M. W. Cho, Tool trajectory generation based on tool deflection effects in flat-end milling process (II) -prediction and compensation of milled surface errors, KSME International Journal, 13(12) (1999) 918–930.

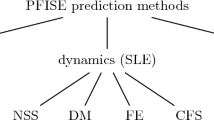

K. Kim, Unavoidable geometric errors in the side walls of end-milled parts -flat surface-, J. of Mech. Science and Tech., 21(1) (2007) 48–56.

K. S. Lee and K. Kim, Unavoidable geometric errors in the side walls of end-milled parts - cylindrical surface-, J. of Mech. Science and Tech., 22 (2008) 522–531.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Dae-Eun Kim

Kun Sang Lee received his B. S. degree in Mechanical Engineering from Seoul National University, Korea, in 1982. He then received his Dipl.-Ing. and Dr.-Ing. degrees from Technical University of Berlin, Germany, in 1991 and 1993, respectively. Dr. Lee is currently a Professor at the School of Mechanical and Automotive Engineering at Kookmin University in Seoul, Korea. He serves as a Staff of the Korea Engineering Education Research Center. His research interests include precision machining, high energy beam material processing, and creative design methodology.

Kang Kim received his B. S. and M. S. degrees in Mechanical Design and Production Engineering from Seoul National University, Korea, in 1982 and 1984, respectively. He then received his Ph.D. degree from Purdue University, USA, in 1992. Dr. Kim is currently a Professor at the School of Mechanical and Automotive Engineering at Kookmin University in Seoul, Korea. His research interests include material removal processes, and concurrent engineering.

Rights and permissions

About this article

Cite this article

Lee, K.S., Kim, K. Analysis of unavoidable geometric errors in the side wall of end-milled parts for corner surface. J Mech Sci Technol 23, 525–535 (2009). https://doi.org/10.1007/s12206-008-1129-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-008-1129-7