Abstract

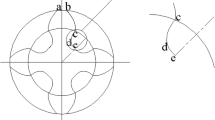

Rotor clearance is necessary for the safe operation of twin-screw compressors, and it has a major impact on the performance of twin-screw compressors. The purpose of this study was to obtain a rotor tooth profile with reasonable meshing clearance on the rotor end surface, so that the clearance on the rotor contact line would be uniform and the rotor could be smoothly meshed. Under ideal conditions, the rotor of a screw compressor should have no clearance or interference. However, owing to assembly errors, thermal compression, stress deformation, and other factors, a rotor without backlash modification will inevitably produce interference during operation. A new design method based on the Alpha shape solution was proposed to achieve an efficient and high-precision design of the clearance of the twin-screw rotor profile. This method avoids the complex analytical calculations in the traditional envelope principle. The best approximation of the points on the rotor conjugate motion sweeping surface in the points is illuminated using a specific color. The sweeping surface of the screw rotor single-tooth profile is roughly scanned to capture the base point set of the sweeping surface boundary points. The chord length and tilt angle of each interval are calculated using the value of the base point set to adjust the position, phase, and magnification of each interval sweeping surface. Finally, the data point set is converted to the same coordinate system to generate the conjugated rotor profile. An example was used to verify the feasibility and adaptability of this method. Based on the equidistant profile method, the clearance between male and female rotors of a screw compressor was obtained under actual operation conditions. Therefore, this study provides a basis for the meshing clearance design in the machining of twin-screw compressor rotors.

摘要

转子间隙是双螺杆压缩机安全运行所需的,对双螺杆压缩机的性能有重大影响。本研究的目的是获得转子端面上具有合理啮合间隙的转子齿廓,使转子接触线上的间隙均匀,使转子啮合光滑。在理想条件下,螺杆压缩机的转子应无间隙或过盈。但由于装配误差、热压缩、应力变形等因素,未进行齿隙改造的转子在运行过程中不可避免地会产生过盈。为了实现双螺杆转子型线间隙的高效高精度设计,提出了一种基于Alpha shape解的双螺杆转子型线间隙设计方法。该方法避免了传统包络原理中复杂的解析计算。转子共轭运动扫描表面上的点的最佳近似是用特定颜色来说明的。对螺杆转子单齿廓的扫面进行粗扫描,获取扫面边界点的基点集。利用基点集的值计算每个间隔的弦长和倾斜角度,调整每个间隔扫描面的位置、相位和放大倍数。最后,将数据点集转换到同一坐标系下生成共轭转子轮廓线。通过实例验证了该方法的可行性和适合性。基于等距轮廓法计算了实际工况下螺杆压缩机内外转子间隙。因此,本研究为双螺杆压缩机转子加工中的啮合间隙设计提供了依据。

Similar content being viewed by others

References

TANG Y, FLEMING J S. Computer aided geometrical analysis of the geometrical characteristics of a helical screw compressor [C]//1st International Compressor Technique Conference. Xi’an: International Institute of Refrigeration, 1993: 400–408.

STOSIC N, SMITH L K, KOVACEVIC A. Calculation of rotor interference in screw compressor [C]//3rd International Compressor Technique Conference. Wuxi: International Institute of Refrigeration, 2001: 134–142.

STOSIC N, SMITH L K, KOVACEVIC A. Rotor interference as a criterion for screw compressor design [J]. Journal of Engineering Design, 2003, 14(2): 209–220.

XIONG W, FENG Q K. Calculation to inter-lobe clearance distribution of twin-screw compressor [J]. Journal of Xi’an Jiaotong University, 2004, 38(7): 682–685. (in Chinese).

XIONG W, FENG Q K. Study of rotor interference in screw compressors based on three dimensions [J]. Chinese Journal of Mechanical Engineering, 2005, 41(6): 55–59. (in Chinese).

LITVIN F L, FUENTES A. Gear geometry and applied theory [M]. Cambridge: Cambridge University Press, 2004.

STOSIC N. On gearing of helical screw compressor rotors [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 1998, 212(7): 587–594.

LǍCRǍMIOARA P C, VIOREL P. Profiling disk tool for generating female rotor screw compressor component by meaning of graphical method [J]. Procedia Manufacturing, 2018, 22: 85–92.

HE K, LI G L, DU Y B, et al. A digital method for calculation the forming cutter profile in machining helical surface [J]. International Journal of Mechanical Sciences, 2019, 155: 370–380.

WU Y R, CHI J W. A numerical method for the evaluation of the meshing clearance for twin screw rotors with discrete tooth profile points [J]. Mechanism and Machine Theory, 2013, 70: 62–73.

LAI J Y, HUANG Y C, LIN F Y, et al. Meshing simulation and clearance evaluation of real screw rotors [J]. Journal of the Chinese Institute of Engineers, 2012, 35(7): 887–900.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, J., Xu, M. & Lu, Z. Design of Twin-Screw Compressor Rotor Tooth Profile with Meshing Clearance Based on Graphic Method and Alpha Shape Algorithm. J. Shanghai Jiaotong Univ. (Sci.) 28, 243–254 (2023). https://doi.org/10.1007/s12204-021-2396-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-021-2396-z