Abstract

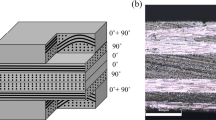

Stripping the polymer coating is the first step for the fabrication of fiber Bragg grating (FBG). The conventional stripping approaches are labor intensive and time consuming. Because of high precision and throughput, as well as non-contacting, laser stripping obtained more and more attention in recent years. This paper reports the primary experiments on laser stripping of polymer coating from FBG using pulsed transverse electric atmospheric (TEA) CO2 laser with wavelength of 10.6 μm and pulse width of 2 μs. Using cylindrical lenses, the coating can be removed thoroughly at one time. The theoretical analysis and experimental investigations were carried out. The influence of laser fluence and pulse number on stripping quality has been investigated. Scanning electron microscopy (SEM), optical microscope, and electrical balance were employed to detect the quality removal. The result shows that excellent quality removal is possible by using pulsed 10.6 μm TEA CO2 laser.

Similar content being viewed by others

References

Zhao Y C, Chen G X, Jian S S, Wang W. Bragg fibre gratings. Optical Communication Technology, 1995, 19(4): 301–304 (in Chinese)

Liu H P, Wang J G, Chen B Q. Multi-axis fiber Bragg gratings and their application in sensing. Optical Fiber & Electric Cable and Their Applications, 2005, (4): 12–15 (in Chinese)

Barber D A, Elbourn P, Greuters J, Rizvi N H. A completely laser-based production method for fibre Bragg grating devices. Optics and Laser Technology, 2003, 35(1): 25–29

Ogura G. Laser stripping of optical fibers opens up new applications. Laser Focus World, 2001, 37(6): 169–176

Obata K, Sugioksa K, Akane T, Aoki N, Toyoda K, Midorikawa K. Influence of laser fluence and irradiation timing of F2 laser on ablation properties of fused silica in F2-KrF excimer laser multiwavelength excitation process. Applied Physics A, 2001, 73(6): 755–759

Zhou X, Imasaki K, Furukawa H, Nakai S, Yamanaka C. Estimation of laser ablation surface cleaning efficiency. The International Journal of Advanced Manufacturing Technology, 2002, 19(9): 642–645

Barnier F, Dyer P E, Monk P, Snelling H V, Rourke H. Fibre optics jacket removal by pulsed laser ablation. Journal of Physics D: Applied Physics, 2000, 33(7): 757–759

Brannon J H, Tam A C, Kurth R H. Pulsed laser stripping of polyurethane-coated wires: a comparison of KrF and CO2 Lasers. Journal of Applied Physics, 1991, 70(7): 3881–3886

Tarpey A J, Kukureka S N, Jurkschat K. The mechanical reliability of stripped and recoated polyimide fibres for optical fibre sensors. Proceedings of SPIE, 2002, 4639: 141–151

Steen W M. Laser Material Processing. London: Springer, 1998

Rubahn H G. Laser Applications in Surface Science and Technology. New York: John Wiley & Sons, 1999

Duley W W. Laser Processing and Analysis of Materials. New York: Plenum Press, 1983

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, H., Lei, W., Dai, C. et al. Laser stripping of fiber Bragg grating polymer coating using pulsed 10.6 μm TEA CO2 laser. Front. Optoelectron. China 3, 303–307 (2010). https://doi.org/10.1007/s12200-010-0097-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12200-010-0097-6