Abstract

High-performance water-based drilling fluids (HPWBFs) are essential to wellbore stability in shale gas exploration and development. Laponite is a synthetic hectorite clay composed of disk-shaped nanoparticles. This paper analyzed the application potential of laponite in HPWBFs by evaluating its shale inhibition, plugging and lubrication performances. Shale inhibition performance was studied by linear swelling test and shale recovery test. Plugging performance was analyzed by nitrogen adsorption experiment and scanning electron microscope (SEM) observation. Extreme pressure lubricity test was used to evaluate the lubrication property. Experimental results show that laponite has good shale inhibition property, which is better than commonly used shale inhibitors, such as polyamine and KCl. Laponite can effectively plug shale pores. It considerably decreases the surface area and pore volume of shale, and SEM results show that it can reduce the porosity of shale and form a seamless nanofilm. Laponite is beneficial to increase lubricating property of drilling fluid by enhancing the drill pipes/wellbore interface smoothness and isolating the direct contact between wellbore and drill string. Besides, laponite can reduce the fluid loss volume. According to mechanism analysis, the good performance of laponite nanoparticles is mainly attributed to the disk-like nanostructure and the charged surfaces.

Similar content being viewed by others

1 Introduction

The concept of high-performance water-based drilling fluids (HPWBF) (Galindo et al. 2015; Jain et al. 2015; Jung et al. 2013; Kosynkin et al. 2011; Morton et al. 2005) has been proposed for decades. HPWBF is defined as water-based drilling fluids (WBF) with good performance parameters, such as good rheology, low filtration, strong shale inhibition, good lubricity, good plugging property, etc., which are important for safe and efficient drilling.

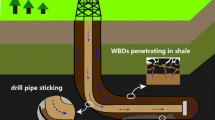

For shale gas reservoirs, the content of clay minerals is as high as 30%–50% or even more (Li et al. 2020b; Yang et al. 2014; Zou et al. 2010). Wellbore instability incidents, such as wellbore collapse, stuck pipe, tight hole, excessive hole, frequently occur. In recent years, the majority of the horizontal sections is drilled by oil-based drilling fluid (OBF) (Li et al. 2014; Sun et al. 2018) to avoid shale hydration (Huang et al. 2018; Jiang et al. 2016; Shadizadeh et al. 2015) and enhance lubrication property (Sönmez et al. 2013). However, the pollution caused by OBF is difficult to handle, which could cause soil contamination and be toxic to marine life. WBF is less polluted and less expensive compared with OBF. Synthetic-based drilling fluids (SBFs) are mainly used in offshore drilling areas. SBFs have good environmental performance (Li et al. 2016a, b, 2019b), strong inhibition and lubricity, and are beneficial to maintain the stability of wellbore, but the cost is high. WBFs have good application prospects in shale gas drilling engineering. However, the drilling mission of shale gas horizontal sections is very difficult to accomplish using WBF recently. Clay swelling, pressure transmission, high drag and torque are among the major factors to cause wellbore instability. The existing HPWBF utilizes high-performance additives such as shale inhibitor (Jiang et al. 2016; Shadizadeh et al. 2015), plugging materials (Riley et al. 2012; Sensoy et al. 2009; Sharma et al. 2012), and lubricating agents (Li et al. 2016c; Sönmez et al. 2013) to achieve the “high performance”.

The majority of the pores in the shale formation are nanoscale (Hoelscher et al. 2012), and microscale particles could not adapt to the nanoscale pores due to their larger sizes. Thus, the combination of nanoplugging agent and shale inhibitor is often utilized to stabilize wellbores drilled in shale gas formations. Recently, the research of nanoscale plugging agents has become a hotspot. The nanoplugging agents attracting more attention recently include inorganic nanoparticles (Hoelscher et al. 2012; Sensoy et al. 2009), nanopolymer spheres (An et al. 2015; Li et al. 2019a; Wang et al. 2013), organic/inorganic nanocomposites (An et al. 2016; Hu et al. 2008), which can reduce fluid invasion and pressure transmission according to evaluation experiments.

An important reason for wellbore instability is the hydration of clay minerals in shales. Shale inhibitor is widely used in WBF to reduce hydration and swelling of clay. The existing inhibitors include inorganic salts, surfactants (Lv et al. 2020; Shadizadeh et al. 2015), polymers, alcohols, and polyamines (Jiang et al. 2016; Zhong et al. 2016), which reduce shale hydration by charge neutralization, wettability reversal, forming isolated layers, reducing surface tension, etc.

For horizontal drilling in shale gas reservoirs, the contact area of the drill pipe with the wellbore is higher than that for vertical drilling, so high drag and torque is another problem (Maliardi et al. 2014), which may cause stuck pipe. The present drilling fluid lubricants include mineral oil, plant oil, modified oil, surfactants, synthetic esters, which reduce drag and torque by isolating contact surface by forming oil films (Chang et al. 2011; Knox and Jiang 2005). Besides, solid lubricants act like ball bearings and isolate the contact surface physically.

In the process of shale gas drilling in China, the existing water-based drilling fluid technology has not solved the technical problems such as instability of the wellbore and high friction due to lack of inhibition, plugging and lubricating performances. Laponite (Na0.7+(Mg5.5Li0.3Si8)O20(OH)4)0.7−) is a synthetic hectorite clay with tri-octahedral 2:1 layered structure (Thompson and Butterworth 1992). The laponite crystals are disk-shaped nanoparticles with a diameter of about 20 nm (Jatav and Joshi 2014; Mongondry et al. 2005) and a thickness of about 1 nm. According to literature research, the laponite is used to enhance the rheological performance (Liu et al. 2017; Xiong et al. 2019) and thermal stability of the drilling fluid (Huang et al. 2019), and to inhibit the shale swelling (Huang et al. 2018). However, little research was carried out on the application of laponite as multifunctional material in water-based drilling fluid for shale gas drilling.

This paper introduces the application of laponite in WBF. The shale inhibition, plugging, and lubrication performances of laponite were evaluated and mechanisms were concisely studied. Experimental results indicated that laponite had good shale inhibition property, plugging property and lubricating property.

2 Experimental

2.1 Materials

Laponite (99.5 wt%) was purchased from Guangzhou Bofeng Chemical Technology Company. Bentonite (99 wt%), polyether amine (99 wt%) and graphite (99.9 wt%) were provided by Greatwall Drilling Company, China. KCl (99.9 wt%) and fumed SiO2 nanoparticles (99.5 wt%, 20 nm) were purchased from J&K Scientific Ltd., China. Outcrop shale samples were taken from Songlin Town, Guanghan city, Sichuan Province, China. The mineral compositions of the shale sample were analyzed by X-ray diffraction, and the results are shown in Table 1.

2.2 Influence of laponite on rheology and filtration of the drilling fluid

The base fluid (4 wt% bentonite suspension) was prepared by slowly adding 16 g of bentonite powder into 400 mL deionized water under 300-rpm stirring. The bentonite suspensions were aged for 24 h at room temperature. 0, 2, 4, 6, and 8 g of laponite were then added to each of 400 mL base fluid, respectively, and kept stirring for 24 h.

Rheological parameters (apparent viscosity, plastic viscosity, yield point, 10-s gel strength and 10-min gel strength) and fluid losses of the prepared drilling fluid samples were measured according to American Petroleum Institute (API) Recommended Practice 13B-1: Recommended Practice Standard Procedure for Testing Drilling Fluids (API RP 13B-1 2009).

2.3 Shale inhibition property of laponite

The shale inhibition performance of laponite suspension was studied by linear swelling test and shale recovery test.

The linear swelling test was carried out using a dual-channel linear swelling tester, whose schematic diagram is shown in Fig. 1. The bentonite pellets were prepared by compressing 10 g of dry bentonite powders under 10 MPa for 5 min and then immersed into 200 mL different inhibitive solutions (aqueous solutions of different shale inhibitors). The linear swelling length (mm) as a function of time was recorded.

The shale recovery test was conducted using a hot rolling oven. 20 g of shale fragments with 6-10 mesh and 350 mL inhibitive solution (aqueous solutions of different shale inhibitors) were transferred into stainless steel rollers and hot-rolled at 150 °C for 16 h. Then the shale fragments were filtered out using a 40-mesh sieve, dried at 105 °C, and weighted (m, g). The shale recovery (R) is calculated from Eq. (1).

where R is the shale recovery and m is the mass of recovered shale fragments, g.

2.4 Plugging performance of laponite

2.4.1 Nitrogen adsorption test

Good plugging performance for nanoscale pores can affect the properties of shale itself, such as reducing the pore volume and specific surface area of shale (Li et al. 2020a; Qiu et al. 2018). The recovered shale fragments before and after the shale recovery test were used for the nitrogen adsorption experiment. An automated gas sorption analyzer (Autosorb-iQ, Quantachrome, USA) was utilized in the experiment. Before measurement, all the samples were evacuated at 300 °C for 2 h. Both the Barrett–Joyner–Halenda (BJH) method and density functional theory (DFT) were used to analyze specific surface area, pore volume and average pore size. All calculations were performed by a built-in software (ASiQwin). Initial shale fragments and the shale fragments immersed in water for 6 h at room temperature were used for comparison.

2.4.2 Morphology

The recovered shale fragments after shale recovery test were dried at 105 ± 1 °C to remove water. The surface morphology of fresh shale fragments and recovered shale fragments was studied by a high-resolution Ultra 55 scanning electron microscope (Zeiss, Germany).

2.5 Extreme pressure lubricity/film strength test

Friction coefficients of the five samples prepared in Sect. 2.2 were measured using an extreme pressure lubrication tester (FANN 212, USA). The pressure applied was 16.95 N·m (150 psi). The reduction of friction coefficients was calculated from Eq. (2).

where μ0 is the friction coefficient of base fluid and μ1 is the friction coefficient of the sample to be tested (base fluid + laponite).

3 Results and discussion

3.1 Introduction of laponite

Laponite (Thompson and Butterworth 1992) is a synthetic hectorite clay, which belong to the family of (2: 1) phyllosilicates built up of sheets of octahedrally coordinated magnesium oxide sandwiched between two parallel sheets of tetrahedrally coordinated silica (Ruzicka and Zaccarelli 2011) (Fig. 2). The laponite crystals are disk-shaped nanoparticles with a diameter of about 20 nm (Jatav and Joshi 2014; Mongondry et al. 2005) and a thickness of about 1 nm. The particle size distribution of 1 wt% laponite suspension was analyzed at room temperature using the Zeta Sizer Nano ZS Instrument (Malvern, UK). The average particle size is 20.62 nm (Fig. 3a), which is in consistence with particle size described in the literature (Thompson and Butterworth 1992). The particle size is also proved by TEM observation as shown in Fig. 3b.

Because the surfaces of laponite nanoparticles are permanently negative-charged and the edges are positively charged (depending on pH), the electrostatic attraction occurs between them and “house of cards” structure forms as shown in Fig. 4a. The size of laponite nanoparticles is much smaller than that of bentonite particles (about several micron), which is one reason of that the gel strength of the laponite suspension is larger than that of the bentonite suspension under the same concentrations. This characteristic makes laponite easy to gel at low concentrations (Ruzicka and Zaccarelli 2011). As shown in Fig. 4b and 4c, laponite suspensions are in gel states at concentrations of 2 wt% and 2.5 wt%. However, the bentonite suspension will not gel at a concentration of 2.5 wt% (Fig. 4d). This stronger gel structure makes laponite possible as an inorganic rheological modifier in drilling fluids (Liu et al. 2017; Xiong et al. 2019).

3.2 Transportability and stability in water

Table 2 shows the basic parameters of laponite. Laponite is a synthetic smectite clay, which is solid-state fine white powder with a bulk density of around 1 g/cm3. So it has good transportability. Fumed silica nanoparticles (Lewis 2018) have extremely low bulk density (usually less than 0.1 g/cm3), which makes it unfriendly to transport. Besides, fumed silica nanoparticles have potential inhalation toxicity which is harmful to the health of operators (Geiser et al. 2017).

The cation exchange capacity of laponite is around 50-60 meq/100 g (Thompson and Butterworth 1992), revealing that laponite has relatively high negative charges and is easy to swell and disperse in water. After dispersion, the disk-shaped nanoscale laponite particles are negatively charged (Huang et al. 2018). The electrostatic repulsion among those nanoparticles makes laponite suspension almost permanently stable and not aggregate or settle. However, the stability of silica nanoparticle suspension is not good, although adjusting the pH to 9–11 could increase the stability of silica nanoparticle suspension, which might be not suitable for application environment (Azadgoleh et al. 2014).

Figure 5a and Fig. 5c are the images of newly prepared aqueous suspensions of 1 wt% laponite and 1 wt% SiO2 nanoparticles, respectively. The 1 wt% SiO2 aqueous suspension was prepared by ultrasonic dispersion for 20 min without adjusting pH. The 1 wt% laponite was prepared by magnetic stirring at 300 rpm for 20 min. The 1 wt% laponite suspension was stable after standing for 5 days (Fig. 5b). However, settlement of SiO2 nanoparticles occurred after standing for 20 min (Fig. 5d). Thus, good transportability and stability make laponite more promising in application.

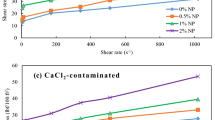

3.3 Shale inhibition property

The shale inhibition performances were evaluated, and comparison tests were made with two commonly used shale inhibitors KCl and polyether amine. Experimental results of the linear swelling test and shale recovery test are shown in Fig. 6a, b, respectively. In linear swelling tests, the 16-hour swelling height of 0.5 wt% laponite was smaller than those of 5 wt% KCl and 2 wt% polyether amine. The shale recovery for water is only 5.4%, which demonstrated that the shale sample was highly reactive. 2.0 wt% laponite obtained the highest shale recovery (55.2%). It is concluded that laponite had good shale inhibition property.

The inhibition mechanism was comprehensively studied in other study (Huang et al. 2018). The reasons for the good shale inhibition of laponite are listed as follows. (1) The surfaces of laponite nanoparticles are permanently negative. At a proper pH value, clay particles have positively charged edges. Electrostatic interaction exists between particle edges (+) of clay and the surfaces (−) of laponite. Thus, laponite nanoparticles can plug interlayer spaces of clays by electrostatic interaction, slowing down the hydration of clays. (2) The capillary suction time (CST) of the laponite suspension increases substantially with an increase in concentration. Thus, laponite suspensions have low free water contents, benefiting to inhibition of clays. (3) The excellent thixotropy enables the laponite suspensions to have a considerably high viscosity on the wellbore wall, which might be helpful to form nanofilms, reducing water invasion. (4) The nanoparticles are effective to plug nanoscale shale pores and form seamless surfaces, preventing water invasion.

3.4 Plugging performance

Nitrogen adsorption experiment is a precise and reliable method which could quantitatively describe the information of pores. BJH and DFT models are two useful methods to analyze shale pores (Sun et al. 2017). BJH model, which is based on Kelvin equation, is more appropriate for the analysis of mesoporous pores (2-50 nm) (Musa et al. 2011). And DFT model is more suitable for the analysis of materials exhibiting a wide range of porosities (Musa et al. 2011). After shale recovery tests, the specific surface area, pore volume and pore size of recovered shale fragments were analyzed by both BJH and DFT to evaluate the plugging performance of the laponite suspension. When the gas adsorption method is used in this experiment, there is a hysteresis loop between the nitrogen adsorption and desorption curves. Therefore, both BJH adsorption and desorption pore size distribution will appear when BJH model is used to do pore analysis. Generally, BJH desorption branch is preferably selected to analyze rock samples for its higher accuracy (Dudek 2016; Li et al. 2019c).

The original shale fragments, shale fragments treated with water, and shale fragments treated with 1 wt% laponite and 2 wt% laponite were tested. Surface area, pore volume and average pore size analyzed by both BJH and DFT model are listed in Table 3. Apparently, for the BJH and DFT models, the changing law of the data is consistent. When contacting with water, the highly reactive shale fragments would certainly swell, the existing pores would grow and new pores were produced. Apparently, immersing in water or laponite suspensions did not influence the average pore size according to Table 3. This is possibly because the production of small new pores balanced the increase in the size of existing pores. After the original shale samples were treated with water, both the surface area and the pore volume appropriately doubled. For shale samples treated with 1 wt% laponite suspension, the surface area and the pore volume also increased, but they were considerably lower than those of shale samples treated with water. In addition, compared with the shale fragments treated by 1 wt% laponite, the shale fragments treated by 2 wt% laponite obtained smaller values in both surface area and pore volume.

The hydration of shale would lead to increases in surface area and pore volume (Li et al. 2020a; Qiu et al. 2018), so water-treated shale samples obtained the largest surface area and pore volume. While laponite-treated shale samples had a lower surface area and pore volume than the water-treated shale, which was due to good inhibition property and plugging performances of laponite.

According to nitrogen adsorption experiment, we cannot draw a conclusion that the plugging performances of laponite is good because of the smaller surface area and pore volume, which might be due to the good inhibition of laponite. So the plugging performance of laponite was further studied by SEM observation. Experimental results are shown in Fig. 7. It is apparent that the original shale fragments are porous and unconsolidated and have many pores and fractures (Fig. 7a). Water from drilling fluids could easily penetrate into shale matrix, leading to wellbore instability. After treatment with 2 wt% laponite suspension, the surface of shale sample became seamless (Fig. 7b), and the majority of pores and fractures disappeared, which would be beneficial to prevent water from penetration (Huang et al. 2018; Li et al. 2015; Yao et al. 2020a; Yao et al. 2020b). In conclusion, laponite suspension can effectively plug pores and fractures of formations.

Shale is a porous medium with many pores and fractures of various scales. In gas reservoirs, capillary suction is a driving force of water infiltration (Luo et al. 2017). More importantly, wellbore pressure penetrates the pore space when water invades the shale. This fluid pressure transmission effect could damage the positive differential pressure that supports the wellbore, resulting in wellbore instability. According to experimental results of SEM observation, laponite could form a seamless nanofilm on the surface of the wellbore, which could reduce capillary imbibition and pressure transmission, benefiting to wellbore stability.

3.5 Influence of laponite on the rheology and filtration of drilling fluids

The influence of the concentration of laponite on the property of 4 wt% bentonite suspension was investigated as shown in Fig. 8. Plastic viscosity is the resistance to the flow of a fluid caused by internal friction. High plastic viscosity means high friction, which harms rate of penetration. According to the Bingham plastic model, the apparent viscosity consists of two parts: plastic viscosity and structural viscosity (Avksentiev and Nikolaev 2017). Laponite can substantially increase the apparent viscosity of the drilling fluid and almost have no influence on the plastic viscosity (Fig. 8a), which means the increase in apparent viscosity is mainly structural viscosity. Yield point is a parameter of the Bingham plastic model and is used to evaluate the ability of the drilling fluid to carry cuttings during circulation. Gel strength demonstrates the ability of the drilling fluid to suspend the cuttings when circulation has ceased. According to Fig. 8b and 8c, the yield point and gel strength increase with an increase in concentration of laponite. The increases in structural viscosity, yield point and gel strength indicate that laponite is beneficial to carry and suspend drill cuttings. Thus, laponite can be used as an inorganic viscosifier in the drilling fluid. Besides, laponite can considerably decrease fluid loss (Fig. 8d) in the studied concentration ranges. The API fluid loss was reduced from 22.8 mL to 13.2 mL when the dosage increased from 0 to 2 wt%. The ability of nanoparticles with appropriate concentrations in WBF to reduce fluid loss has been reported in many literature (Liu et al. 2015; Sensoy et al. 2009). The results of filtration tests achieved are in accordance with the literature.

3.6 Influence of laponite on lubricating property

The reduction of friction coefficients of base fluids with different laponite concentrations was measured. Experimental results are shown in Fig. 9. As the concentration of laponite increased from 0 to 2 wt%, the reduction of friction coefficients increased from 11.3% to 32.3%. The friction reduction of 1 wt% graphite, which is a commonly used solid lubricant, was 47.6%. Although laponite did not reach the performance of the special-purpose lubricant, it could considerably increase lubricating property of drilling fluid.

The friction reducing mechanism has been investigated in a number of recent studies (Chen et al. 2015; Kong et al. 2017; Li et al. 2016c). Based on these studies, the lubricating mechanism of laponite was concluded as shown in Fig. 10. First, laponite could enhance the interface smoothness. Nanoscale laponite particles could adsorb on the surface of both metal and shale matrix, forming smooth and protective films (Fig. 10a). The interface of wellbore contacted with drill string is coarse and irregular. For concaves on the surface with an appropriate size, the laponite could fill the caves and mend the flaw, improving surface smoothness (Fig. 10b). And laponite could work as a polishing agent to remove the small protuberance on the shale matrix (Fig. 10c). Second, laponite could isolate the direct contact between wellbore and drill string, and thus the friction between them turns into the sliding of crystal layers (Fig. 10d), which substantially reduces friction. Besides, the protective film formed is beneficial to protect the drill string from wear under extreme pressure.

4 Conclusions

This paper introduced the application of laponite in WBF. The shale inhibition property, plugging property, lubrication property of laponite and its compatibility with WBF were studied. Several conclusions can be drawn as follows:

-

1.

The linear swelling test and shale recovery test show that laponite has better shale inhibition property than polyether amine and KCl.

-

2.

The nitrogen adsorption experiment proves that laponite-treated shale has lower surface area and pore volume in comparison with shale samples treated with water. And SEM observation shows laponite could form a seamless nanofilm on the surface of the wellbore. Nitrogen adsorption experiment and SEM observation indicate that laponite has good plugging property of shale.

-

3.

Laponite can increase lubricating property of the drilling fluid by enhancing the interface smoothness and isolating the direct contact between wellbore and drill strings.

-

4.

Laponite can increase the apparent viscosity of drilling fluid and almost has no influence on the plastic viscosity. Thus, laponite is a potential inorganic viscosifier in the drilling fluid. Besides, laponite could be helpful to decrease fluid loss in the studied concentration ranges.

References

An Y, Jiang G, Qi Y, Ge Q, Zhang L, Ren Y. Synthesis of nano-plugging agent based on AM/AMPS/NVP terpolymer. J Pet Sci Eng. 2015;135:505–14. https://doi.org/10.1016/j.petrol.2015.10.014.

An Y, Jiang G, Qi Y, Huang X, Shi H. High-performance shale plugging agent based on chemically modified graphene. J Nat Gas Sci Eng. 2016;32:347–55. https://doi.org/10.1016/j.jngse.2016.04.048.

API RP 13B-1. Recommended practice for field testing water-based drilling fluids. API 4th Edition; 2009.

Avksentiev SY, Nikolaev AK. Influence of rheology on pressure losses in hydrotransport system of polymetallic ores tailings. In: IOP Conf. Ser. Earth Environ. Sci. 2017;87(5). https://doi.org/10.1088/1755-1315/87/5/052019.

Azadgoleh JE, Kharrat R, Barati N, Sobhani A. Stability of silica nanoparticle dispersion in brine solution: an experimental study. Iran J Oil Gas Sci Technol. 2014;3(4):26–40. https://doi.org/10.22050/ijogst.2014.7485.

Chang ZY, Breeden D, McDonald M. The use of zinc dialkyl dithiophosphate as a lubricant enhancer for drilling fluids particularly silicate-based drilling fluids. In: SPE Int. Symp. Oilf. Chem. Society of Petroleum Engineers; 2011. https://doi.org/10.2118/141327-ms.

Chen Z, Liu X, Liu Y, Gunsel S, Luo J. Ultrathin MoS2 nanosheets with superior extreme pressure property as boundary lubricants. Sci. Rep. 2015;5:12869. https://doi.org/10.1038/srep12869.

Dudek L. Pore size distribution in shale gas deposits based on adsorption isotherm analyses. Nafta-Gaz. 2016;8:603–9. https://doi.org/10.18668/ng.2016.08.03.

Galindo KA, Zha W, Zhou H, Deville JP. High performance water-based drilling fluid for extreme high temperature wells. In: SPE/IADC Drill. Conf. Proc. Society of Petroleum Engineers; 2015. https://doi.org/10.2118/173773-ms.

Geiser M, Jeannet N, Fierz M, Burtscher H. Evaluating adverse effects of inhaled nanoparticles by realistic in vitro technology. Nanomaterials. 2017;7(2):49. https://doi.org/10.3390/nano7020049.

Hoelscher KP, De Stefano G, Riley M, Young S. Application of nanotechnology in drilling fluids. In: SPE Int. Oilf. Nanotechnol. Conf. Exhib. Society of Petroleum Engineers; 2012. http://www.onepetro.org/doi/10.2118/157031-MS.

Hu J, Ma J, Deng W. Properties of acrylic resin/nano-SiO2 leather finishing agent prepared via emulsifier-free emulsion polymerization. Mater Lett. 2008;62(17–18):2931–4. https://doi.org/10.1016/j.matlet.2008.01.127.

Huang X, Shen H, Sun J, Lv K, Liu J, Dong X, et al. Nanoscale laponite as a potential shale inhibitor in water-based drilling fluid for stabilization of wellbore stability and mechanism study. ACS Appl Mater Interfaces. 2018;10(39):33252–9. https://doi.org/10.1021/acsami.8b11419.

Huang X, Lv K, Sun J, Lu Z, Bai Y, Shen H, et al. Enhancement of thermal stability of drilling fluid using laponite nanoparticles under extreme temperature conditions. Mater Lett. 2019;248:146–9. https://doi.org/10.1016/j.matlet.2019.04.005.

Jain R, Mahto V, Sharma VP. Evaluation of polyacrylamide-grafted-polyethylene glycol/silica nanocomposite as potential additive in water based drilling mud for reactive shale formation. J Nat Gas Sci Eng. 2015;26:526–37. https://doi.org/10.1016/j.jngse.2015.06.051.

Jatav S, Joshi YM. Chemical stability of laponite in aqueous media. Appl Clay Sci. 2014;97:72–7. https://doi.org/10.1016/j.clay.2014.06.004.

Jiang G, Qi Y, An Y, Huang X, Ren Y. Polyethyleneimine as shale inhibitor in drilling fluid. Appl Clay Sci. 2016;127:70–7. https://doi.org/10.1016/j.clay.2016.04.013.

Jung CM, Zhang R, Chenevert M, Sharma M. High-performance water-based mud using nanoparticles for shale reservoirs. In: Unconv. Resour. Technol. Conf. 2013, URTC 2013. Society of Petroleum Engineers; 2013. https://doi.org/10.1190/urtec2013-106.

Knox D, Jiang P. Drilling further with water-based fluids—selecting the right lubricant. In: SPE Int. Symp. Oilf. Chem. Society of Petroleum Engineers; 2005. https://doi.org/10.2523/92002-ms.

Kong L, Sun J, Bao Y. Preparation, characterization and tribological mechanism of nanofluids. RSC Adv. 2017;7(21):12599–609. https://doi.org/10.1039/c6ra28243a.

Kosynkin DV, Ceriotti G, Wilson KC, Lomeda JR, Scorsone JT, Patel AD, et al. Graphene oxide as a high-performance fluid-loss-control additive in water-based drilling fluids. ACS Appl Mater Interfaces. 2011;4(1):222–7. https://doi.org/10.1021/am2012799.

Lewis RC. Silica fume. RILEM State-of-the-Art Reports. 2018. p. 99–121. https://doi.org/10.1007/978-3-319-70606-1_3.

Li H, Lv K, Huang X, Lu Z, Dong X. The synthesis of polymeric nanospheres and the application as high-temperature nano-plugging agent in water based drilling fluid. Front Chem. 2020a;8:247. https://doi.org/10.3389/fchem.2020.00247.

Li J, Yang P, Guan J, Sun Y, Kuang X, Chen S. A new type of whole oil-based drilling fluid. Pet Explor Dev. 2014;41(4):538–44. https://doi.org/10.1016/S1876-3804(14)60064-1.

Li W, Zhao X, Li Y, Ji Y, Peng H, Liu L, et al. Laboratory investigations on the effects of surfactants on rate of penetration in rotary diamond drilling. J Pet Sci Eng. 2015. https://doi.org/10.1016/j.petrol.2015.07.027.

Li W, Zhao X, Ji Y, Peng H, Chen B, Liu L, et al. Investigation of biodiesel-based drilling fluid, part 1: biodiesel evaluation, invert-emulsion properties, and development of a novel emulsifier package. SPE J. 2016a;21(5):1755–66. https://doi.org/10.2118/180918-PA.

Li W, Zhao X, Ji Y, Peng H, Chen B, Liu L, et al. Investigation of biodiesel-based drilling fluid, part 2: formulation design, rheological study, and laboratory evaluation. SPE J. 2016b;21(5):1767–81. https://doi.org/10.2118/180926-PA.

Li W, Liu J, Zeng J, Tian J, Li L, Zhang M, et al. A critical review of the application of nanomaterials in frac fluids: The state of the art and challenges. In: SPE Middle East Oil Gas Show Conf. MEOS, Proc. 2019a. https://doi.org/10.2118/195029-ms.

Li W, Liu J, Zhao X, Jiang J, Peng H, Zhang M, et al. Development and screening of additives for biodiesel based drilling fluids: Principles, strategies and experience. In: SPE Int. Conf. Oilf. Chem. 2019b. https://doi.org/10.2118/193597-ms.

Li W, Zhao X, Peng H, Guo J, Ji T, Chen B, et al. A novel environmentally friendly lubricant for water-based drilling fluids as a new application of biodiesel. In: IADC/SPE Asia Pacific Drill. Technol. Conf. 2016c. https://doi.org/10.2118/180565-ms.

Li W, Liu J, Zeng J, Leong YK, Elsworth D, Tian J, et al. A fully coupled multidomain and multiphysics model for evaluation of shale gas extraction. Fuel. 2020b;278:118214. https://doi.org/10.1016/j.fuel.2020.118214.

Li X, Gao Z, Fang S, Ren C, Yang K, Wang F. Fractal characterization of nanopore structure in shale, tight sandstone and mudstone from the ordos basin of China using nitrogen adsorption. Energies. 2019;12(4):583. https://doi.org/10.3390/en12040583.

Liu F, Jiang G-C, Wang K, Wang J. Laponite nanoparticle as a multi-functional additive in water-based drilling fluids. J Mater Sci 2017;52(20):12266–78. https://doi.org/10.1007/s10853-017-1375-0.

Liu JY, Qiu ZS, Huang W. Novel latex particles and aluminum complexes as potential shale stabilizers in water-based drilling fluids. J Pet Sci Eng. 2015;135:433–41. https://doi.org/10.1016/j.petrol.2015.10.003.

Luo Z, Wang L, Yu P, Chen Z. Experimental study on the application of an ionic liquid as a shale inhibitor and inhibitive mechanism. Appl Clay Sci. 2017;150:267–74. https://doi.org/10.1016/j.clay.2017.09.038.

Lv K, Huang X, Li H, Sun J, Du W, Li M. Modified bio-surfactant cationic alkyl polyglycoside as an effective additive for inhibition of highly reactive shale. Energy Fuels. 2020;34(2):1680–7. https://doi.org/10.1021/acs.energyfuels.9b04131.

Maliardi A, Sergiacomo M, Del Gaudio L. Successful application of innovative technology improves lubricity of high performance water-based mud systems in challenging environments. In: Int. Pet. Technol. Conf. 2014, IPTC 2014. 2014. https://doi.org/10.2523/iptc-18217-ms.

Mongondry P, Tassin JF, Nicolai T. Revised state diagram of laponite dispersions. J Colloid Interface Sci. 2005;283(2):397–405. https://doi.org/10.1016/j.jcis.2004.09.043.

Morton K, Bomar B, Schiller M, Gallet J, Azar S, Dye W, et al. Selection and evaluation criteria for high-performance drilling fluids. In: SPE Annu. Tech. Conf. Exhib. 2005. https://doi.org/10.2523/96342-ms.

Musa MAA, Yin CY, Savory RM. Analysis of the textural characteristics and pore size distribution of a commercial zeolite using various adsorption models. J Appl Sci. 2011;11(21):3650–4. https://doi.org/10.3923/jas.2011.3650.3654.

Qiu Z, Xu J, Yang P, Zhao X, Mou T, Zhong H, et al. Effect of amphiphilic polymer/nano-silica composite on shale stability for water-based muds. Appl Sci. 2018;8:1839. https://doi.org/10.3390/app8101839.

Riley M, Young S, Stamatakis E, Guo Q, Ji L, De Stefano G, et al. Wellbore stability in unconventional shales—the design of a nano-particle fluid. In: SPE Oil Gas India Conf. Exhib. Society of Petroleum Engineers; 2012. http://www.onepetro.org/doi/10.2118/153729-MS.

Ruzicka B, Zaccarelli E. A fresh look at the laponite phase diagram. Soft Matter. 2011. https://doi.org/10.1039/c0sm00590h.

Sensoy T, Chenevert ME, Sharma MM. Minimizing water invasion in shale using nanoparticles. In: SPE Annu. Tech. Conf. Exhib. Society of Petroleum Engineers; 2009. https://doi.org/10.2118/124429-ms.

Shadizadeh SR, Moslemizadeh A, Dezaki AS. A novel nonionic surfactant for inhibiting shale hydration. Appl Clay Sci. 2015;118:74–86. https://doi.org/10.1016/j.clay.2015.09.006.

Sharma MM, Chenevert ME, Guo Q, Ji L, Friedheim J, Zhang R. A new family of nanoparticle based drilling fluids. In: SPE Annu. Tech. Conf. Exhib. Society of Petroleum Engineers; 2012. http://www.onepetro.org/doi/10.2118/160045-MS.

Sönmez A, Verşan Kök M, Özel R. Performance analysis of drilling fluid liquid lubricants. J Pet Sci Eng. 2013;108:64–73. https://doi.org/10.1016/j.petrol.2013.06.002.

Sun J, Huang X, Jiang G, Lyu K, Liu J, Dai Z. Development of key additives for organoclay-free oil-based drilling mud and system performance evaluation. Pet Explor Dev. 2018;45(4):764–9. https://doi.org/10.1016/S1876-3804(18)30079-X.

Sun M, Yu B, Hu Q, Zhang Y, Li B, Yang R, et al. Pore characteristics of Longmaxi shale gas reservoir in the Northwest of Guizhou, China: investigations using small-angle neutron scattering (SANS), helium pycnometry, and gas sorption isotherm. Int J Coal Geol. 2017;171:61–8. https://doi.org/10.1016/j.coal.2016.12.004.

Thompson DW, Butterworth JT. The nature of laponite and its aqueous dispersions. J Colloid Interface Sci. 1992;151(1):236–43. https://doi.org/10.1016/0021-9797(92)90254-J.

Wang JH, Li JN, Yan LL, Ji YH. Preparation of a novel nano-polymer as plugging and filtration loss agent for oil-based drilling fluids. Adv Mater Res Trans Tech Publ; 2013. p. 2602–6. http://www.scientific.net/AMR.807-809.2602.

Xiong ZQ, Li XD, Fu F, Li YN. Performance evaluation of laponite as a mud-making material for drilling fluids. Pet Sci. 2019;16(4):890–900. https://doi.org/10.1007/s12182-018-0298-y.

Yang F, Ning Z, Liu H. Fractal characteristics of shales from a shale gas reservoir in the Sichuan Basin, China. Fuel. 2014;115:378–84. https://doi.org/10.1016/j.fuel.2013.07.040.

Yao C, Liu B, Li L, Zhang K, Lei G, Steenhuis TS. Transport and retention behaviors of deformable polyacrylamide microspheres in convergent−divergent microchannels. Environ Sci Technol. 2020a. https://doi.org/10.1021/acs.est.0c02243.

Yao C, Zhan G, Zhao J, Wang N, Lei G, Zhang K, et al. Experimental investigation of molecular deposition filming flooding in a low-permeability oil reservoir. Energy Fuels. 2020b;34(6):6938–50. https://doi.org/10.1021/acs.energyfuels.0c00819.

Zhong H, Qiu Z, Tang Z, Zhang X, Xu J, Huang W. Study of 4,4′-methylenebis-cyclohexanamine as a high temperature-resistant shale inhibitor. J Mater Sci. 2016;51(16):7585–97. https://doi.org/10.1007/s10853-016-0037-y.

Zou C, Dong D, Wang S, Li J, Li X, Wang Y, et al. Geological characteristics and resource potential of shale gas in China. Pet Explor Dev. 2010;37(6):641–53. https://doi.org/10.1016/S1876-3804(11)60001-3.

Acknowledgements

The authors are thankful to the National Natural Science Foundation of China (U1762212, 51904329, 41902323), CNPC Science and Technology Project (No. 2018A-3907), Shandong Natural Science Foundation (ZR2019BEE002), the Opening Fund of Key Laboratory of Unconventional Oil and Gas Development (China University of Petroleum (East China)), Ministry of Education (19CX05005A-7), the Fundamental Research Funds for the Central Universities (No. 18CX02171A), and Scientific Research Foundation for the Introduction of Talents (YJ20170014).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Edited by Yan-Hua Sun

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Huang, XB., Sun, JS., Huang, Y. et al. Laponite: a promising nanomaterial to formulate high-performance water-based drilling fluids. Pet. Sci. 18, 579–590 (2021). https://doi.org/10.1007/s12182-020-00516-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12182-020-00516-z