Abstract

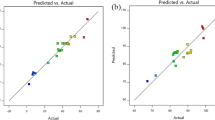

This study investigates the correlation between both the chemical compositions and physicochemical properties of pretreated oil palm empty fruit bunch (OPEFB) fibre and their enzymatic saccharification/total glucose yield (TGY). Twenty OPEFB samples, pretreated with various aqueous pretreatments, with diverse cellulose (25.63–44.23%), hemicellulose (0.01–42.49%), and lignin (3.7–47.1%) levels, were examined for their correlation with TGY (8.5–40%). The quadratic regression model was verified significant (p-value = 0.0006, R2 = 0.8006). It was found that the pre-refined OPEFB experienced greater cellulose loss (35%) compared to unrefined ones (9%), adversely affecting TGY. Among physicochemical properties analysed using SEM, FTIR, XRD, Py-GCMS, and XPS, only crystallinity index (CrI) was significantly correlated with TGY based on theoretical glucose concentration (TGC) (R2 = 0.77, 0.91). Other characteristics (morphology, functional groups, crystallite size, S/G ratio, and O/C ratio) exhibited no significant correlation to saccharification efficiency, exhibiting random trends (R2 < 0.5). OPEFB fibres with CrI of 30–40 could achieve 100% TGY based on TGC. In conclusion, regardless of pretreatments, chemical compositions predominantly affected TGY in the enzymatic saccharification of biomass. Among commonly used physicochemical analytical methods, CrI is most significant in this evaluation and OPEFB should be unrefined before treatment to avoid cellulose loss.

Graphical Abstract

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

Baruah J, Nath BK, Sharma R, Kumar S, Deka RC, Baruah DC, Kalita E (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res 6. https://doi.org/10.3389/fenrg.2018.00141

Zoghlami A, Paës G (2019) Lignocellulosic biomass: understanding recalcitrance and predicting hydrolysis. Front Chem 7:874. https://doi.org/10.3389/fchem.2019.00874

Tong KTX, Tan IS, Foo HCY, Lam MK, Lim S, Lee KT (2022) Advancement of biorefinery-derived platform chemicals from macroalgae: a perspective for bioethanol and lactic acid. Biomass Convers Biorefin 14:1443–1479. https://doi.org/10.1007/s13399-022-02561-7

Tang ZY, Li L, Tang W, Shen JW, Yang QZ, Ma C, He YC (2023) Significantly enhanced enzymatic hydrolysis of waste rice hull through a novel surfactant-based deep eutectic solvent pretreatment. Bioresour Technol 381:129106. https://doi.org/10.1016/j.biortech.2023.129106

Tye YY, Lee KT, Wan Abdullah WN, Leh CP (2015) Effects of process parameters of various pretreatments on enzymatic hydrolysability of Ceiba pentandra (L.) Gaertn. (Kapok) fibre: a response surface methodology study. Biomass Bioenergy 75:301–313. https://doi.org/10.1016/j.biombioe.2015.02.034

Usmani Z, Sharma M, Gupta P, Karpichev Y, Gathergood N, Bhat R, Gupta VK (2020) Ionic liquid based pretreatment of lignocellulosic biomass for enhanced bioconversion. Bioresour Technol 304:123003. https://doi.org/10.1016/j.biortech.2020.123003

del Mar C-Gámez M, Galán-Martín Á, Seixas N, da Costa Lopes AM, Silvestre A, Castro E (2023) Deep eutectic solvents for improved biomass pretreatment: current status and future prospective towards sustainable processes. Bioresour Technol 369:128396. https://doi.org/10.1016/j.biortech.2022.128396

Płotka-Wasylka J, de la Guardia M, Andruch V, Vilková M (2020) Deep eutectic solvents vs ionic liquids: similarities and differences. Microchem J 159:105539. https://doi.org/10.1016/j.microc.2020.105539

Valladares-Diestra KK, de Souza P, Vandenberghe L, Nishida VS, Zevallos Torres LA, Zandoná Filho A, Soccol CR (2022) Integrated sugarcane biorefinery for first- and second-generation bioethanol production using imidazole pretreatment. J Clean Prod 381:135179. https://doi.org/10.1016/J.JCLEPRO.2022.135179

Tye YY, Leh CP, Wan Abdullah WN (2017) Total glucose yield as the single response in optimizing pretreatments for Elaeis guineensis fibre enzymatic hydrolysis and its relationship with chemical composition of fibre. Renew Energy 114:383–393. https://doi.org/10.1016/j.renene.2017.07.040

Tye YY, Lee KT, Wan Abdullah WN, Leh CP (2016) Optimization of various pretreatments condition of kenaf core (Hibiscus cannabinus) fibre for sugar production: effect of chemical compositions of pretreated fibre on enzymatic hydrolysability. Renew Energy 99:205–215. https://doi.org/10.1016/j.renene.2016.06.040

Buratti C, Foschini D, Barbanera M, Fantozzi F (2018) Fermentable sugars production from peach tree prunings: response surface model optimization of NaOH alkaline pretreatment. Biomass Bioenergy 112:128–137. https://doi.org/10.1016/j.biombioe.2017.12.032

Luo X, Liu J, Zheng P, Li M, Zhou Y, Huang L, Chen L, Shuai L (2019) Promoting enzymatic hydrolysis of lignocellulosic biomass by inexpensive soy protein. Biotechnol Biofuels 12. https://doi.org/10.1186/s13068-019-1387-x

Sharma L, Alam NM, Roy S, Satya P, Kar G, Ghosh S, Goswami T, Majumdar B (2023) Optimization of alkali pretreatment and enzymatic saccharification of jute (Corchorus olitorius L.) biomass using response surface methodology. Bioresour Technol 368:128318. https://doi.org/10.1016/j.biortech.2022.128318

Zhang H, Huang S, Wei W, Zhang J, Xie J (2019) Investigation of alkaline hydrogen peroxide pretreatment and Tween 80 to enhance enzymatic hydrolysis of sugarcane bagasse. Biotechnol Biofuels 12. https://doi.org/10.1186/s13068-019-1454-3

Liu ZH, Qin L, Pang F, Jin MJ, Li BZ, Kang Y, Dale BE, Yuan YJ (2013) Effects of biomass particle size on steam explosion pretreatment performance for improving the enzyme digestibility of corn stover. Ind Crops Prod 44:176–184. https://doi.org/10.1016/j.indcrop.2012.11.009

Jeong SY, Koo B, Lee JW (2022) Structural changes in biomass (yellow poplar and empty fruit bunch) during hydrothermal and oxalic acid pretreatments and their effects on enzymatic hydrolysis efficiency. Ind Crops Prod 178:114569. https://doi.org/10.1016/J.INDCROP.2022.114569

Luo L, Yuan X, Zhang S, Wang X, Li M, Wang S (2021) Effect of pretreatments on the enzymatic hydrolysis of high-yield bamboo chemo-mechanical pulp by changing the surface lignin content. Polymers (Basel) 13:787. https://doi.org/10.3390/polym13050787

Spiridon I, Teacǎ CA, Bodîrlǎu R (2011) Structural changes evidenced by FTIR spectroscopy in cellulosic materials after pre-treatment with ionic liquid and enzymatic hydrolysis. Bioresources 6:400–413. https://doi.org/10.15376/biores.6.1.400-413

Sun SF, Yang HY, Yang J, Shi ZJ (2022) The effect of alkaline extraction of hemicellulose on cocksfoot grass enzymatic hydrolysis recalcitrance. Ind Crops Prod 178:114654. https://doi.org/10.1016/j.indcrop.2022.114654

Zhang Y, Huang M, Su J, Hu H, Yang M, Huang Z, Chen D, Wu J, Feng Z (2019) Overcoming biomass recalcitrance by synergistic pretreatment of mechanical activation and metal salt for enhancing enzymatic conversion of lignocellulose. Biotechnol Biofuels 12. https://doi.org/10.1186/s13068-019-1354-6

Yuan Y, Jiang B, Chen H, Wu W, Wu S, Jin Y, Xiao H (2021) Recent advances in understanding the effects of lignin structural characteristics on enzymatic hydrolysis. Biotechnol Biofuels 14. https://doi.org/10.1186/s13068-021-02054-1

Ma Ah Ngan (1999) Environmental management for the palm oil industry. Palm Oil Developments 30:1–10

US Department of Agriculture, Foreign Agricultural Service (2022) https://ipad.fas.usda.gov/cropexplorer/cropview/commodityView.aspx?cropid=4243000. In: Palm Oil Explorer. https://ipad.fas.usda.gov/cropexplorer/cropview/commodityView.aspx?cropid=4243000. Accessed 7 Nov 2022

Loh SK (2017) The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers Manag 141:285–298. https://doi.org/10.1016/j.enconman.2016.08.081

Zhu JY, Pan XJ, Wang GS, Gleisner R (2009) Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour Technol 100:2411–2418. https://doi.org/10.1016/j.biortech.2008.10.057

Tang PL, Hong WL, Yue CS, Harun S (2020) Palm oil mill effluent as the pretreatment solvent of oil palm empty fruit bunch fiber for fermentable sugars production. Bioresour Technol 314:123723. https://doi.org/10.1016/j.biortech.2020.123723

Luo X, Gong Z, Shi J, Chen L, Zhu W, Zhou Y, Huang L, Liu J (2020) Integrating benzenesulfonic acid pretreatment and bio-based lignin-shielding agent for robust enzymatic conversion of Cellulose in Bamboo. Polymers (Basel) 12:191. https://doi.org/10.3390/polym12010191

Chong YH, Ng SH, Leh CP (2013) Improved oxygen delignification selectivity of oil palm (Elaeis guineensis) EFB Soda-AQ pulp: effect of photo-pretreatment and AQ-aided H2O2 reinforcement. Cellul Chem Technol 47:277–283. https://doi.org/10.1016/j.msec.2019.02.027

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268. https://doi.org/10.1351/pac198759020257

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3. https://doi.org/10.1186/1754-6834-3-10

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Tong W, Fang H, Song K, Xie X, Wang J, Jin Y, Wu S, Hu J, Chu Q (2023) Modified acid pretreatment to alter physicochemical properties of biomass for full cellulose/hemicellulose utilization. Carbohydr Polym 299:120182. https://doi.org/10.1016/j.carbpol.2022.120182

Li M, Pu Y, Ragauskas AJ (2016) Current understanding of the correlation of lignin structure with biomass recalcitrance. Front Chem 4. https://doi.org/10.3389/fchem.2016.00045

Huang C, Zhan Y, Du X, Zhou Y, Yu L, Meng X, Jiao J, Fang G, Ragauskas AJ (2020) Modified alkaline peroxide pretreatment: an efficient path forward for bioethanol production from bamboo. Energy Convers Manag 224:113365. https://doi.org/10.1016/j.enconman.2020.113365

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112. https://doi.org/10.1016/j.biortech.2015.10.009

Li X, Li M, Pu Y, Ragauskas AJ, Klett AS, Thies M, Zheng Y (2018) Inhibitory effects of lignin on enzymatic hydrolysis: the role of lignin chemistry and molecular weight. Renew Energy 123:664–674. https://doi.org/10.1016/j.renene.2018.02.079

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenergy Res 6:405–415. https://doi.org/10.1007/s12155-012-9276-1

Kubovský I, Kačíková D, Kačík F (2020) Structural changes of oak wood main components caused by thermal modification. Polymers (Basel) 12:485. https://doi.org/10.3390/polym12020485

Das P, Stoffel RB, Area MC, Ragauskas AJ (2019) Effects of one-step alkaline and two-step alkaline/dilute acid and alkaline/steam explosion pretreatments on the structure of isolated pine lignin. Biomass Bioenergy 120:350–358. https://doi.org/10.1016/j.biombioe.2018.11.029

Fougere D, Nanda S, Clarke K, Kozinski JA, Li K (2016) Effect of acidic pretreatment on the chemistry and distribution of lignin in aspen wood and wheat straw substrates. Biomass Bioenergy 91:56–68. https://doi.org/10.1016/j.biombioe.2016.03.027

Traoré M, Kaal J, Martínez Cortizas A (2018) Differentiation between pine woods according to species and growing location using FTIR-ATR. Wood Sci Technol 52:487–504. https://doi.org/10.1007/s00226-017-0967-9

Santos TM, Alonso MV, Oliet M, Domínguez JC, Rigual V, Rodriguez F (2018) Effect of autohydrolysis on Pinus radiata wood for hemicellulose extraction. Carbohydr Polym 194:285–293. https://doi.org/10.1016/j.carbpol.2018.04.010

Acquah GE, Via BK, Fasina OO, Eckhardt LG (2016) Rapid quantitative analysis of forest biomass using Fourier transform infrared spectroscopy and partial least squares regression. J Anal Methods Chem 2016. https://doi.org/10.1155/2016/1839598

Toscano G, Maceratesi V, Leoni E, Stipa P, Laudadio E, Sabbatini S (2022) FTIR spectroscopy for determination of the raw materials used in wood pellet production. Fuel 313:123017. https://doi.org/10.1016/J.FUEL.2021.123017

Mandal A, Chakrabarty D (2011) Isolation of nanocellulose from waste sugarcane bagasse (SCB) and its characterization. Carbohydr Polym 86:1291–1299. https://doi.org/10.1016/j.carbpol.2011.06.030

Pardo LMF, Mendoza JGS, Galán JEL (2019) Influence of pretreatments on crystallinity and enzymatic hydrolysis in sugar cane residues. Braz J Chem Eng 36:131–141. https://doi.org/10.1590/0104-6632.20190361s20180093

Pramasari DA, Haditjaroko L, Sunarti TC, Hermiati E, Syamsu K (2017) The effectiveness of physical and alkali hydrothermal pretreatment <br> in improving enzyme susceptibility of sweet sorghum bagasse. J Bahan Alam Terbarukan 6: 117–131. https://doi.org/10.15294/jbat.v6i2.9910

Prosper NK, Zhang S, Wu H, Yang S, Li S, Sun F, Goodell B (2018) Enzymatic biocatalysis of bamboo chemical constituents to impart antimold properties. Wood Sci Technol 52:619–635. https://doi.org/10.1007/s00226-018-0987-0

Park J, Jones B, Koo B, Chen X, Tucker M, Yu JH, Pschorn T, Venditti R, Park S (2016) Use of mechanical refining to improve the production of low-cost sugars from lignocellulosic biomass. Bioresour Technol 199:59–67. https://doi.org/10.1016/j.biortech.2015.08.059

Acknowledgements

The contribution of OPEFB biomass by United Oil Palm Mill, Nibong Tebal, Penang, Malaysia, was greatly appreciated.

Funding

This work was supported by The Ministry of Higher Education (MoHE) through the Fundamental Research Grant Scheme (FRGS) (203/PTEKIND/6711702).

Author information

Authors and Affiliations

Contributions

Hemashini D/O Tannimalay: methodology, conceptualisation, software, formal analysis, investigation, resources, data curation, writing — original draft, visualisation. Associate Professor Dr Leh Cheu Peng: conceptualisation, methodology, validation, resources, writing — review and editing, supervision, project administration, funding acquisition. Associate Professor Dr Lee Chee Keong: methodology, co-supervision. Dr Goh Choon Fu: co-supervision, writing — review and editing. Dr Tye Ying Ying: investigation. Dr Maya Ismayati: formal analysis, investigation, resources. Dr. H’ng Yin Ying: conceptualisation, methodology.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Lignocellulosic compositions of OPEFB significantly correlate to total glucose yield.

• For OPEFB, hemicellulose removal has a bigger impact than lignin on boosting TGY.

• Chemical treatment on unrefined OPEFB retains cellulose better than refined one.

• Among physicochemical changes, only CrI shows a significant correlation with TGY.

• OPEFB with CrI within 30 to 40 is conducive to achieving TGY approaching 100%.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hemashini, T., Lee, C.K., Goh, C.F. et al. Elucidating the Correlation of Lignocellulosic Compositions and Physicochemical Alterations in Oil Palm (Elaeis guineensis) Biomass on Enzymatic Saccharification Yield. Bioenerg. Res. (2024). https://doi.org/10.1007/s12155-024-10762-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12155-024-10762-3