Abstract

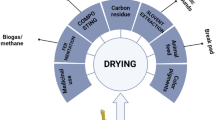

The current study aimed at sequential anthocyanin extraction and bioethanol production from eggplant peel with a zero waste approach. For this purpose, the effect of different solvents (100% ethanol, 100% methanol, 50/50% ethanol-water, and 50/50% methanol-water) on anthocyanin extraction was investigated in the first stage. Lignocellulosic residues of eggplant peel which remained from anthocyanin extraction were subjected to enzymatic hydrolysis, and bioethanol was produced through the fermentation process in the second stage. During experiments, the effect of initial biomass loading on anthocyanin extraction and bioethanol production was also tested. The highest anthocyanin concentration was found as 2306.1 ± 3.5 mg/kg when 50/50% ethanol-water was used as a solvent in the presence of 20% eggplant peel. The maximum ethanol concentrations were observed in enzymatically hydrolyzed 15% eggplant peel loading as 27.5 g/L and 26.6 g/L, for S. cerevisiae and K. marxianus, respectively. In the same conditions, volumetric ethanol productivities were 0.76 g/L.h and 0.74 g/L.h for the same microorganisms. Theoretical ethanol yields were also calculated as 89.6% (YP/S: 0.48 g/g) and 86.8% (YP/S: 0.48 g/g). This study demonstrates that eggplant peel is a promising raw material for biorefinery approaches.

Graphical Abstract

Similar content being viewed by others

References

Hassan SS, Williams GA, Jaiswal AK (2018) Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour Technol 262:310–318. https://doi.org/10.1016/j.biortech.2018.04.099

Diep NQ, Sakanishi K, Nakagoshi N et al (2012) Biorefinery: concepts , current status , and development trends biorefinery: concepts , current status , and development trends. Int J biomass renewables 1:1–8

Patel A, Shah AR (2021) Integrated lignocellulosic biorefinery: gateway for production of second generation ethanol and value added products. J Bioresour Bioprod 6:108–128. https://doi.org/10.1016/j.jobab.2021.02.001

Zabed H, Sahu JN, Suely A et al (2017) Bioethanol production from renewable sources: current perspectives and technological progress. Renew Sustain Energy Rev 71:475–501. https://doi.org/10.1016/j.rser.2016.12.076

Kumar P, Barrett DM, Delwiche MJ, Stroeve P (2009) Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind Eng Chem Res 48:3713–3729. https://doi.org/10.1021/ie801542g

Chen J, Xu B, Sun J et al (2021) Anthocyanin supplement as a dietary strategy in cancer prevention and management: a comprehensive review. Crit Rev Food Sci Nutr 62:7242–7254. https://doi.org/10.1080/10408398.2021.1913092

Todaro A, Cimino F, Rapisarda P et al (2009) Recovery of anthocyanins from eggplant peel. Food Chem 114:434–439. https://doi.org/10.1016/j.foodchem.2008.09.102

Karimi A, Kazemi M, Samani SA, Simal-Gandara J (2021) Bioactive compounds from by-products of eggplant: functional properties, potential applications and advances in valorization methods. Trends Food Sci Technol 112:518–531. https://doi.org/10.1016/j.tifs.2021.04.027

Dranca F, Oroian M (2016) Optimization of ultrasound-assisted extraction of total monomeric anthocyanin (TMA) and total phenolic content (TPC) from eggplant (Solanum melongena L.) peel. Ultrason Sonochem 31:637–646. https://doi.org/10.1016/j.ultsonch.2015.11.008

Xu S, Li G, Zhou J et al (2022) Efficient production of anthocyanins in Saccharomyces cerevisiae by introducing anthocyanin transporter and knocking out endogenous degrading enzymes. Front Bioeng Biotechnol 10:899182. https://doi.org/10.3389/fbioe.2022.899182

Leonard E, Yan Y, Fowler ZL et al (2008) Strain improvement of recombinant Escherichia coli for efficient production of plant flavonoids. Mol Pharm 5:257–265. https://doi.org/10.1021/mp7001472

Durmaz Y, Kilicli M, Toker OS et al (2020) Using spray-dried microalgae in ice cream formulation as a natural colorant: effect on physicochemical and functional properties. Algal Res 47:101811. https://doi.org/10.1016/j.algal.2020.101811

Uçkun Kiran E, Trzcinski AP, Ng WJ, Liu Y (2014) Bioconversion of food waste to energy: a review. Fuel 134:389–399. https://doi.org/10.1016/j.fuel.2014.05.074

Lennartsson PR, Erlandsson P, Taherzadeh MJ (2014) Integration of the first and second generation bioethanol processes and the importance of by-products. Bioresour Technol 165:3–8. https://doi.org/10.1016/j.biortech.2014.01.127

Jambo SA, Abdulla R, Mohd Azhar SH et al (2016) A review on third generation bioethanol feedstock. Renew Sustain Energy Rev 65:756–769. https://doi.org/10.1016/j.rser.2016.07.064

Lugani Y, Rai R, Prabhu AA et al (2020) Recent advances in bioethanol production from lignocelluloses: a comprehensive review with a focus on enzyme engineering and designer biocatalysts. Biofuel Res J 7:1267–1295. https://doi.org/10.18331/BRJ2020.7.4.5

Safaripour M, Ghanbari A, Seyedabadi E, Pourhashem G (2021) Investigation of environmental impacts of bioethanol production from wheat straw in Kermanshah, Iran. Biomass Convers Biorefinery 13:5931–5941. https://doi.org/10.1007/s13399-021-01676-7

Chen X, Shekiro J, Franden MA et al (2012) The impacts of deacetylation prior to dilute acid pretreatment on the bioethanol process. Biotechnol Biofuels 5(8):1–14 http://www.biotechnologyforbiofuels.com/content/5/1/8

Adney B, Baker J (2008) Measurement of cellulase activities laboratory analytical procedure (LAP), pp 1–11. https://doi.org/10.1016/j.biortech.2006.01.007

Giusti M, Wrolstad R (2001) Characterization and measurement of anthocyanins by UV-visible spectroscopy. Curr Protoc Food Anal Chem 1:1–13. https://doi.org/10.1002/0471142913.faf0102s00

Wistara NJ, Pelawi R, Fatriasari W (2016) The effect of lignin content and freeness of pulp on the bioethanol productivity of Jabon wood. Waste and Biomass Valorization 7:1141–1146. https://doi.org/10.1007/s12649-016-9510-8

Motoda T, Yamaguchi M, Tsuyama T, Kamei I (2019) Down-regulation of pyruvate decarboxylase gene of white-rot fungus Phlebia sp. MG-60 modify the metabolism of sugars and productivity of extracellular peroxidase activity. J Biosci Bioeng 127:66–72. https://doi.org/10.1016/j.jbiosc.2018.06.017

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Kim TH, Lee YY (2007) Pretreatment of corn stover by soaking in aqueous ammonia at moderate temperatures. Appl Biochem Biotechnol 136:81–82

Roca C, Olsson L (2003) Increasing ethanol productivity during xylose fermentation by cell recycling of recombinant Saccharomyces cerevisiae. Appl Microbiol Biotechnol 60:560–563. https://doi.org/10.1007/s00253-002-1147-9

Günan Yücel H, Aksu Z (2015) Ethanol fermentation characteristics of Pichia stipitis yeast from sugar beet pulp hydrolysate: use of new detoxification methods. Fuel 158:793–799. https://doi.org/10.1016/j.fuel.2015.06.016

Philippi K, Tsamandouras N, Grigorakis S, Makris DP (2016) Ultrasound-Assisted Green Extraction of Eggplant Peel (Solanum melongena) polyphenols using aqueous mixtures of glycerol and ethanol: optimisation and kinetics. Environ Process 3:369–386. https://doi.org/10.1007/s40710-016-0140-8

Suresh T, Sivarajasekar N, Balasubramani K et al (2020) Process intensification and comparison of bioethanol production from food industry waste (potatoes) by ultrasonic assisted acid hydrolysis and enzymatic hydrolysis: statistical modelling and optimization. Biomass and Bioenergy 142:105752. https://doi.org/10.1016/j.biombioe.2020.105752

Azmir J, Zaidul ISM, Rahman MM et al (2013) Techniques for extraction of bioactive compounds from plant materials: a review. J Food Eng 117:426–436. https://doi.org/10.1016/j.jfoodeng.2013.01.014

Kähkönen MP, Hopia AI, Heinonen M (2001) Berry phenolics and their antioxidant activity. J Agric Food Chem 49:4076–4082. https://doi.org/10.1021/jf010152t

Ferarsa S, Zhang W, Moulai-Mostefa N et al (2018) Recovery of anthocyanins and other phenolic compounds from purple eggplant peels and pulps using ultrasonic-assisted extraction. Food Bioprod Process 109:19–28. https://doi.org/10.1016/j.fbp.2018.02.006

Ioelovich M, Morag E (2012) Study of enzymatic hydrolysis of pretreated biomass at increased solids loading. Bioresour 7:4672–4682. https://doi.org/10.15376/biores.7.4.4672-4682

Koppram R, Olsson L (2014) Combined substrate, enzyme and yeast feed in simultaneous saccharification and fermentation allow bioethanol production from pretreated spruce biomass at high solids loadings. Biotechnol Biofuels 7:1–9. https://doi.org/10.1186/1754-6834-7-54

Narra M, James JP, Balasubramanian V (2015) Simultaneous saccharification and fermentation of delignified lignocellulosic biomass at high solid loadings by a newly isolated thermotolerant Kluyveromyces sp. for ethanol production. Bioresour Technol 179:331–338. https://doi.org/10.1016/j.biortech.2014.11.116

Thomson JM, Gaucher EA, Burgan MF et al (2005) Resurrecting ancestral alcohol dehydrogenases from yeast. Nat Genet 37:630–635. https://doi.org/10.1038/ng1553

Jin X, Ma J, Song J, Liu GQ (2021) Promoted bioethanol production through fed-batch semisimultaneous saccharification and fermentation at a high biomass load of sodium carbonate-pretreated rice straw. Energy 226:120353. https://doi.org/10.1016/j.energy.2021.120353

Karimi K, Emtiazi G, Taherzadeh MJ (2006) Ethanol production from dilute-acid pretreated rice straw by simultaneous saccharification and fermentation with Mucor indicus, Rhizopus oryzae, and Saccharomyces cerevisiae. Enzyme Microb Technol 40:138–144. https://doi.org/10.1016/j.enzmictec.2005.10.046

Funding

This study was supported by the Ankara University Research Foundation, project no: 21L0430012.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Demiray, E., Gerbağa, A., Karatay, S.E. et al. Sequential Anthocyanin Extraction and Ethanol Production from Eggplant Peel Through Biorefinery Approach. Bioenerg. Res. 17, 383–391 (2024). https://doi.org/10.1007/s12155-023-10631-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-023-10631-5