Abstract

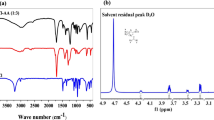

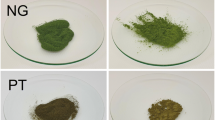

Lipid extraction from microalgal biomass faces some challenges such as the selection of a suitable biomass type and its quality, lipid yield (LY), and process energy consumption. This study aimed to develop optimized processing conditions using response surface methodology, for the ultrasonic extraction (UE) of lipids from wet and dried marine Chlorella sp. Integrated process approaches with different extraction and solvent recovery steps were developed for the evaluation of the lipid recovery and process energy consumption. The effects of other processing factors, such as the biomass-to-solvent ratio, solvent type, and solvent-to-solvent ratio were investigated. The biomass and lipids extracted were characterized by scanning electron microscopy-energy-dispersive X-ray (SEM-EDX) and gas chromatography-flame ionization detection (GC-FID) analysis, respectively. With a single extraction and single-solvent recovery (1-1 cycle) process, the LYs from fresh and stored paste were 11.7% and 6%, respectively, while freeze-dried biomass produced an 18.5% LY. The energy consumption was 6000 MJ/kg lipid for the wet route and 8200 MJ/kg lipid for the dry route in the 1-1-cycle process. Dried biomass was selected for further investigation due to its longer storage-period capability and higher LY. The LY of the 2-1-cycle process using methanol/hexane (2/1 v/v) with a biomass-to-solvent ratio of 1/20 g/mL was 31% and was considered as a base case scenario of this study, which is 40.3% and 9.7% greater than those of the 1-1 cycle and 2-2 cycle, respectively. The lipids obtained from the 2-1 cycle at the optimum condition were mainly saturated fatty acids which are suitable for a biodiesel feedstock.

Similar content being viewed by others

References

Dragone G, Fernandes B, Vicente A, Teixeira J (2010) Third generation biofuels from microalgae. Curr Res Technol Educ Top Appl Microbiol Microb Biotechnol 1355–1366. https://doi.org/10.1016/j.apenergy.2011.03.012

Chisti Y (2008) Biodiesel from microalgae beats bioethanol. Trends Biotechnol 26:126–131. https://doi.org/10.1016/j.tibtech.2007.12.002

Liu AY, Chen W, Zheng LL, Song LR (2011) Identification of high-lipid producers for biodiesel production from forty-three green algal isolates in China. Prog Nat Sci Mater Int 21:269–276. https://doi.org/10.1016/S1002-0071(12)60057-4

Nascimento IA, Marques SSI, Cabanelas ITD, Pereira SA, Druzian JI, de Souza CO, Vich DV, de Carvalho GC, Nascimento MA (2013) Screening microalgae strains for biodiesel production: lipid productivity and estimation of fuel quality based on fatty acids profiles as selective criteria. Bioenergy Res 6:1–13. https://doi.org/10.1007/s12155-012-9222-2

Nascimento IA, Marques SSI, Cabanelas ITD, de Carvalho GC, Nascimento MA, de Souza CO, Druzian JI, Hussain J, Liao W (2014) Microalgae versus land crops as feedstock for biodiesel: productivity, quality, and standard compliance. Bioenergy Res. https://doi.org/10.1007/s12155-014-9440-x

Hussain J, Liu Y, Lopes WA, Druzian JI, Souza CO, Carvalho GC, Nascimento IA, Liao W (2015) Effects of different biomass drying and lipid extraction methods on algal lipid yield, fatty acid profile, and biodiesel quality. Appl Biochem Biotechnol 175:3048–3057. https://doi.org/10.1007/s12010-015-1486-5

Schenk PM, Thomas-Hall SR, Stephens E, Marx UC, Mussgnug JH, Posten C, Kruse O, Hankamer B (2008) Second generation biofuels: high-efficiency microalgae for biodiesel production. Bioenergy Res 1:20–43. https://doi.org/10.1007/s12155-008-9008-8

Quinn JC, Catton K, Wagner N, Bradley TH (2012) Current large-scale US biofuel potential from microalgae cultivated in photobioreactors. Bioenergy Res 5:49–60. https://doi.org/10.1007/s12155-011-9165-z

Mata TM, Martins AA, Caetano NS (2010) Microalgae for biodiesel production and other applications: a review. Renew Sust Energ Rev 14:217–232. https://doi.org/10.1016/j.rser.2009.07.020

Mandik YI, Cheirsilp B, Boonsawang P, Prasertsan P (2015) Optimization of flocculation efficiency of lipid-rich marine Chlorella sp. biomass and evaluation of its composition in different cultivation modes. Bioresour Technol 182:89–97. https://doi.org/10.1016/j.biortech.2015.01.125

Kelaiya SV, Chauhan PM, Akbari SH (2015) Fuel property of biodiesel made from microalgae (Chlorella sp.). Curr World Environ 10:912–919

Phukan MM, Chutia RS, Konwar BK, Kataki R (2011) Microalgae Chlorella as a potential bio-energy feedstock. Appl Energy 88:3307–3312. https://doi.org/10.1016/j.apenergy.2010.11.026

Kay RA, Barton LL (1991) Microalgae as food and supplement. Crit Rev Food Sci Nutr 30:555–573. https://doi.org/10.1080/10408399109527556

Paisan S, Chetpattananondh P, Chongkhong S (2017) Assessment of water degumming and acid degumming of mixed algal oil. J Environ Chem Eng 5:5115–5123. https://doi.org/10.1016/j.jece.2017.09.045

Uprety BK, Venkatesagowda B, Rakshit SK (2017) Current prospects on production of microbial lipid and other value-added products using crude glycerol obtained from biodiesel industries. Bioenergy Res 10:1117–1137

Li YG, Xu L, Huang YM, Wang F, Guo C, Liu CZ (2011) Microalgal biodiesel in China: opportunities and challenges. Appl Energy 88:3432–3437. https://doi.org/10.1016/j.apenergy.2010.12.067

Sharma KK, Li Y, Schenk PM (2015) Rapid lipid induction in Chlorella sp. by UV-C radiation. Bioenergy Res 8:1824–1830. https://doi.org/10.1007/s12155-015-9633-y

Sanyano N, Chetpattananondh P, Chongkhong S (2013) Coagulation-flocculation of marine Chlorella sp. for biodiesel production. Bioresour Technol 147:471–476. https://doi.org/10.1016/j.biortech.2013.08.080

Bagchi SK, Rao PS, Mallick N (2015) Development of an oven drying protocol to improve biodiesel production for an indigenous chlorophycean microalga Scenedesmus sp. Bioresour Technol 180:207–213. https://doi.org/10.1016/j.biortech.2014.12.092

Konda NVSNM, Singh S, Simmons BA, Klein-Marcuschamer D (2015) An investigation on the economic feasibility of macroalgae as a potential feedstock for biorefineries. Bioenergy Res 8:1046–1056. https://doi.org/10.1007/s12155-015-9594-1

Lam MK, Lee KT (2012) Microalgae biofuels: a critical review of issues, problems and the way forward. Biotechnol Adv 30:673–690

Pang S, Mujumdar AS (2010) Drying of woody biomass for bioenergy: drying technologies and optimization for an integrated bioenergy plant. Dry Technol 28:690–701. https://doi.org/10.1080/07373931003799236

Villagracia ARC, Mayol AP, Ubando AT, Biona JBMM, Arboleda NB, David MY, Tumlos RB, Lee H, Lin OH, Espiritu RA, Culaba AB, Kasai H (2016) Microwave drying characteristics of microalgae (Chlorella vulgaris) for biofuel production. Clean Techn Environ Policy 18:2441–2451. https://doi.org/10.1007/s10098-016-1169-0

Hosseinizand H, Sokhansanj S, Lim CJ (2017) Studying the drying mechanism of microalgae Chlorella vulgaris and the optimum drying temperature to preserve quality characteristics. Dry Technol 1–12

Show KY, Lee DJ, Tay JH, Lee TM, Chang JS (2015) Microalgal drying and cell disruption - recent advances. Bioresour Technol 184:258–266. https://doi.org/10.1016/j.biortech.2014.10.139

Chen P, Min M, Chen Y et al (2009) Review of the biological and engineering aspects of algae to fuels approach. Int J Agric Biol Eng 2:1–30

Kadam KL (2002) Environmental implications of power generation via coal-microalgae cofiring. Energy 27:905–922. https://doi.org/10.1016/S0360-5442(02)00025-7

Dong T, Knoshaug EP, Pienkos PT, Laurens LML (2016) Lipid recovery from wet Oleaginous microbial biomass for biofuel production: a critical review. Appl Energy 177:879–895

Martinez-Guerra E, Gude VG, Mondala A, Holmes W, Hernandez R (2014) Microwave and ultrasound enhanced extractive-transesterification of algal lipids. Appl Energy 129:354–363. https://doi.org/10.1016/j.apenergy.2014.04.112

Lee JY, Yoo C, Jun SY, Ahn CY, Oh HM (2010) Comparison of several methods for effective lipid extraction from microalgae. Bioresour Technol 101:S75–S77. https://doi.org/10.1016/j.biortech.2009.03.058

Prabakaran P, Ravindran AD (2011) A comparative study on effective cell disruption methods for lipid extraction from microalgae. Lett Appl Microbiol 53:150–154

Gerde JA, Montalbo-Lomboy M, Yao L, Grewell D, Wang T (2012) Evaluation of microalgae cell disruption by ultrasonic treatment. Bioresour Technol 125:175–181. https://doi.org/10.1016/j.biortech.2012.08.110

Yang F, Xiang W, Sun X, Wu H, Li T, Long L (2014) A novel lipid extraction method from wet microalga Picochlorum sp. at room temperature. Mar Drugs 12:1258–1270. https://doi.org/10.3390/md12031258

Araujo GS, Matos LJBL, Fernandes JO, Cartaxo SJM, Gonçalves LRB, Fernandes FAN, Farias WRL (2013) Extraction of lipids from microalgae by ultrasound application: prospection of the optimal extraction method. Ultrason Sonochem 20:95–98. https://doi.org/10.1016/j.ultsonch.2012.07.027

Guldhe A, Singh B, Rawat I, Ramluckan K, Bux F (2014) Efficacy of drying and cell disruption techniques on lipid recovery from microalgae for biodiesel production. Fuel 128:46–52. https://doi.org/10.1016/j.fuel.2014.02.059

Mushtaq M, Sultana B, Bhatti HN, Asghar M (2015) RSM based optimized enzyme-assisted extraction of antioxidant phenolics from underutilized watermelon (Citrullus lanatus Thunb.) rind. J Food Sci Technol 52:5048–5056. https://doi.org/10.1007/s13197-014-1562-9

Sweeney RA, Rexroad PR (1986) Comparison of LECO FP-228 "nitrogen determinator" with AOAC copper catalyst Kjeldahl method for crude protein. J Assoc Off Anal Chem 70:1028–1030

Sumanta N, Haque CI, Nishika J, Suprakash R (2014) Spectrophotometric analysis of chlorophylls and carotenoids from commonly grown fern species by using various extracting solvents. Res J Chem Sci Res J Chem Sci 4:2231–2606

Ali M, Watson I (2015) Microwave treatment of wet algal paste for enhanced solvent extraction of lipids for biodiesel production. Renew Energy 76:470–477. https://doi.org/10.1016/j.renene.2014.11.024

Zheng H, Yin J, Gao Z, Huang H, Ji X, Dou C (2011) Disruption of Chlorella vulgaris cells for the release of biodiesel-producing lipids: a comparison of grinding, ultrasonication, bead milling, enzymatic lysis, and microwaves. Appl Biochem Biotechnol 164:1215–1224. https://doi.org/10.1007/s12010-011-9207-1

Balasubramanian RK, Yen Doan TT, Obbard JP (2013) Factors affecting cellular lipid extraction from marine microalgae. Chem Eng J 215–216:929–936. https://doi.org/10.1016/j.cej.2012.11.063

Taher H, Al-Zuhair S, Al-Marzouqi AH et al (2014) Effective extraction of microalgae lipids from wet biomass for biodiesel production. Biomass Bioenergy 66:159–167. https://doi.org/10.1016/j.biombioe.2014.02.034

Lee AK, Lewis DM, Ashman PJ (2012) Disruption of microalgal cells for the extraction of lipids for biofuels: processes and specific energy requirements. Biomass Bioenergy 46:89–101. https://doi.org/10.1016/j.biombioe.2012.06.034

Chen L, Liu T, Zhang W, Chen X, Wang J (2012) Biodiesel production from algae oil high in free fatty acids by two-step catalytic conversion. Bioresour Technol 111:208–214. https://doi.org/10.1016/j.biortech.2012.02.033

Wu J, Alam MA, Pan Y, Huang D, Wang Z, Wang T (2017) Enhanced extraction of lipids from microalgae with eco-friendly mixture of methanol and ethyl acetate for biodiesel production. J Taiwan Inst Chem Eng 71:323–329. https://doi.org/10.1016/j.jtice.2016.12.039

Orr VCA, Plechkova NV, Seddon KR, Rehmann L (2016) Disruption and wet extraction of the microalgae Chlorella vulgaris using room-temperature ionic liquids. ACS Sustain Chem Eng 4:591–600. https://doi.org/10.1021/acssuschemeng.5b00967

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917. https://doi.org/10.1139/o59-099

Reddy HK, Muppaneni T, Ponnusamy S, Sudasinghe N, Pegallapati A, Selvaratnam T, Seger M, Dungan B, Nirmalakhandan N, Schaub T, Holguin FO, Lammers P, Voorhies W, Deng S (2016) Temperature effect on hydrothermal liquefaction of Nannochloropsis gaditana and Chlorella sp. Appl Energy 165:943–951. https://doi.org/10.1016/j.apenergy.2015.11.067

Moser BR (2009) Biodiesel production, properties, and feedstocks. In Vitro Cell Dev Biol Plant 45:229–266. https://doi.org/10.1007/s11627-009-9204-z

Sathish A, Sims RC (2012) Biodiesel from mixed culture algae via a wet lipid extraction procedure. Bioresour Technol 118:643–647. https://doi.org/10.1016/j.biortech.2012.05.118

Zhao W, Duan M, Zhang X, Tan T (2018) A mild extraction and separation procedure of polysaccharide, lipid, chlorophyll and protein from Chlorella spp. Renew Energy 118:701–708. https://doi.org/10.1016/j.renene.2017.11.046

Chakdar H, Pabbi S (2017) Algal pigments for human health and cosmeceuticals. In: Algal Green Chemistry: Recent Progress in Biotechnology. Elsevier B.V., pp 171–188.

Redel-Macías MD, Pinzi S, Ruz MF, Cubero-Atienza AJ, Dorado MP (2012) Biodiesel from saturated and monounsaturated fatty acid methyl esters and their influence over noise and air pollution. Fuel. 97:751–756. https://doi.org/10.1016/j.fuel.2012.01.070

Pinzi S, Leiva D, Arzamendi G, Gandia LM, Dorado MP (2011) Multiple response optimization of vegetable oils fatty acid composition to improve biodiesel physical properties. Bioresour Technol 102:7280–7288. https://doi.org/10.1016/j.biortech.2011.05.005

Ferreira AF, Dias APS, Silva CM, Costa M (2016) Effect of low frequency ultrasound on microalgae solvent extraction: analysis of products, energy consumption and emissions. Algal Res 14:9–16. https://doi.org/10.1016/j.algal.2015.12.015

Halim R, Harun R, Danquah MK, Webley PA (2012) Microalgal cell disruption for biofuel development. Appl Energy 91:116–121. https://doi.org/10.1016/j.apenergy.2011.08.048

Adam F, Abert-Vian M, Peltier G, Chemat F (2012) “Solvent-free” ultrasound-assisted extraction of lipids from fresh microalgae cells: a green, clean and scalable process. Bioresour Technol 114:457–465. https://doi.org/10.1016/j.biortech.2012.02.096

Acknowledgments

This research was financially supported by Thailand’s Education Hub for Southern Region of ASEAN Countries (TEH-AC, 56/2016) granted by the Graduate School, Prince of Songkla University (PSU), Hat Yai, Songkhla, Thailand. We are grateful to the Department of Chemical Engineering, Faculty of Engineering, PSU, for providing all facilities and supporting staff to accomplish this work. We are really thankful to the Research and Development Office (RDO), PSU, for their support in English language editing and proofreading.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Amin, M., Chetpattananondh, P. Enhanced Lipid Recovery from Marine Chlorella Sp. by Ultrasonication with an Integrated Process Approach for Wet and Dry Biomass. Bioenerg. Res. 12, 665–679 (2019). https://doi.org/10.1007/s12155-019-09986-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-019-09986-5