Abstract

Powdered activated carbon-treated lignocellulosic syrup prepared from energy cane bagasse was evaluated as a potential feedstock in the production of fumaric acid by Rhizopus oryzae ATCC® 20344™. Energy cane bagasse was pretreated with dilute ammonia and enzymatically hydrolyzed with commercially available enzymes, Cellic® CTec2 and HTec2. The collected hydrolysate samples were subjected to powdered activated carbon adsorption for the removal of non-sugar compounds (i.e., organic acids, furaldehydes, total phenolic compounds) and concentrated to a final 65°Bx syrup (mostly xylose and glucose sugars). The use of lignocellulosic syrup, the effect of nitrogen source, medium additives, and initial pH in the seed culture medium on fungal morphology were investigated. The carbon to nitrogen (C/N) ratio in the acid production medium was also optimized for maximum yields in fumaric acid production. Optimum seed culture medium conditions (2.0 g/L urea, 3.0 pH) produced the desired compact, smooth, and uniform fungal pellets. Optimum acid production medium conditions (400 C/N ratio, 0.2 g/L urea) resulted in a fumaric acid production of 34.20 g/L, with a yield of 0.43 g/g and a productivity of 0.24 g/L/h. These results were comparable to those observed with the control medium (pure glucose and xylose). The present study demonstrated that lignocellulosic syrup processed from dilute ammonia pretreated energy cane bagasse has potential as a renewable carbon source for fumaric acid fermentation by Rhizopus oryzae ATCC® 20344™.

Similar content being viewed by others

References

Liu H, Wang W, Deng L, Wang F, Tan T (2015) High production of fumaric acid from xylose by newly selected strain Rhizopus arrhizus RH 7-13-9. Bioresour Technol 186:348–350

Engel CAR, Van Gulik WM, Marang L, Van der Wielen LA, Straathof AJ (2011) Development of a low pH fermentation strategy for fumaric acid production by Rhizopus oryzae. Enzym Microb Technol 48(1):39–47

Zhang K, Yu C, Yang S-T (2015) Effects of soybean meal hydrolysate as the nitrogen source on seed culture morphology and fumaric acid production by Rhizopus oryzae. Process Biochem 50(2):173–179

Choi S, Song CW, Shin JH, Lee SY (2015) Biorefineries for the production of top building block chemicals and their derivatives. Metab Eng 28:223–239

Moharregh-Khiabani D, Linker RA, Gold R, Stangel M (2009) Fumaric acid and its esters: an emerging treatment for multiple sclerosis. Curr Neuropharmacol 7(1):60–64

Zhang K, Zhang B, Yang S-T (2013) Production of citric, itaconic, fumaric, and malic acids in filamentous fungal fermentations. In: Bioprocessing technologies in biorefinery for sustainable production of fuels, chemicals, and polymers. John Wiley & Sons, Inc., Hoboken, pp 375–398

Roa Engel CA, Straathof AJJ, Zijlmans TW, van Gulik WM, van der Wielen LAM (2008) Fumaric acid production by fermentation. Appl Microbiol Biotechnol 78(3):379–389

Mondala AH (2015) Direct fungal fermentation of lignocellulosic biomass into itaconic, fumaric, and malic acids: current and future prospects. J Ind Microbiol Biotechnol 42(4):487–506

Zhou Y, Du J, Tsao GT (2000) Mycelial pellet formation by Rhizopus oryzae ATCC 20344. Appl Biochem Biotechnol 84(1):779–789

Liao W, Liu Y, Frear C, Chen S (2007) A new approach of pellet formation of a filamentous fungus—Rhizopus oryzae. Bioresour Technol 98(18):3415–3423

Xu Q, Li S, Fu Y, Tai C, Huang H (2010) Two-stage utilization of corn straw by Rhizopus oryzae for fumaric acid production. Bioresour Technol 101(15):6262–6264

Xu Q, Li S, Huang H, Wen J (2012) Key technologies for the industrial production of fumaric acid by fermentation. Biotechnol Adv 30(6):1685–1696

Moresi M, Parente E, Petruccioli M, Federici F (1991) Optimization of fumaric acid production from potato flour by Rhizopus arrhizus. Appl Microbiol Biotechnol 36(1):35–39

Moresi M, Parente E, Petruccioli M, Federici F (1992) Fumaric acid production from hydrolysates of starch-based substrates. J Chem Technol Biotechnol 54(3):283–290

Petruccioli M, Angiani E, Federici F (1996) Semi-continuous fumaric acid production by Rhizopus arrhizus immobilized in polyurethane sponge. Process Biochem 31(5):463–469

Carta FS, Soccol CR, Ramos LP, Fontana JD (1999) Production of fumaric acid by fermentation of enzymatic hydrolysates derived from cassava bagasse. Bioresour Technol 68(1):23–28

Liao W, Liu Y, Frear C, Chen S (2008) Co-production of fumaric acid and chitin from a nitrogen-rich lignocellulosic material—dairy manure—using a pelletized filamentous fungus Rhizopus oryzae ATCC 20344. Bioresour Technol 99(13):5859–5866

Rodríguez-López J, Sánchez AJ, Gómez DM, Romaní A, Parajó JC (2012) Fermentative production of fumaric acid from Eucalyptus globulus wood hydrolyzates. J Chem Technol Biotechnol 87(7):1036–1040

Aita GA, Salvi DA, Walker MS (2011) Enzyme hydrolysis and ethanol fermentation of dilute ammonia pretreated energy cane bagasse. Bioresour Technol 102(6):4444–4448

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74(1):25–33

Hu F, Ragauskas A (2012) Pretreatment and lignocellulosic chemistry. Bioenergy Res 5(4):1043–1066

Chandel AK, da Silva SS, Singh OV (2013) Detoxification of lignocellulose hydrolysates: biochemical and metabolic engineering toward white biotechnology. Bioenergy Res 6(1):388–401

Deng F, Aita GM (2018) Detoxification of dilute ammonia pretreated energy cane bagasse enzymatic hydrolysate by soluble polyelectrolyte flocculants. Ind Crop Prod 112:681–690

Lee JM, Venditti RA, Jameel H, Kenealy WR (2011) Detoxification of woody hydrolyzates with activated carbon for bioconversion to ethanol by the thermophilic anaerobic bacterium Thermoanaerobacterium saccharolyticum. Biomass Bioenergy 35(1):626–636

Mateo S, Roberto IC, Sánchez S, Moya AJ (2013) Detoxification of hemicellulosic hydrolyzate from olive tree pruning residue. Ind Crop Prod 49:196–203

Rosatella AA, Simeonov SP, Frade RF, Afonso CA (2011) 5-Hydroxymethylfurfural (HMF) as a building block platform: biological properties, synthesis and synthetic applications. Green Chem 13:754–793

Kamal SMM, Mohamad NL, Abdullah AGL, Abdullah N (2011) Detoxification of sago trunk hydrolysate using activated charcoal for xylitol production. Procedia Food Sci 1:908–913

Ghose T (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270

Baş D, Boyacı İH (2007) Modeling and optimization I: usability of response surface methodology. J Food Eng 78:836–845

Khataee AR, Fathinia M, Aber S, Zarei M (2010) Optimization of photocatalytic treatment of dye solution on supported TiO2 nanoparticles by central composite design: intermediates identification. J Hazard Mater 181:886–897

Somers TC, Ziemelis G (1985) Spectral evaluation of total phenolic components in Vitis vinifera: grapes and wines. J Sci Food Agric 36(12):1275–1284

Singh K, Nizam S, Sinha M, Verma PK (2012) Comparative transcriptome analysis of the necrotrophic fungus Ascochyta rabiei during oxidative stress: insight for fungal survival in the host plant. PLoS One 7(3):e33128

Larsson S, Palmqvist E, Hahn-Hägerdal B, Tengborg C, Stenberg K, Zacchi G, Nilvebrant N-O (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzym Microb Technol 24(3):151–159

Behera S, Arora R, Nandhagopal N, Kumar S (2014) Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew Sust Energ Rev 36:91–106

Cataldelli V, Akasaki JL, Melges JLP, Tashima MM, Soriano L, Borrachero M, Monzo J, Paya J (2013) Use of slag/sugar cane bagasse ash (SCBA) blends in the production of alkali-activated materials. Materials (Basel) 6:3108–3127

Ahlgren S, Baky A, Bernesson S, Nordberg Å, Norén O, Hansson P-A (2008) Future fuel supply systems for organic production based on Fischer–Tropsch diesel and dimethyl ether from on-farm-grown biomass. Biosyst Eng 99(1):145–155

Jenkins B, Baxter L, Miles T (1998) Combustion properties of biomass. Fuel Process Technol 54(1):17–46

El Khattabi MO, Alaoui Hafidi MR, El Midaoui A (1996) Reduction of melassigenic ions in cane sugar juice by electrodialysis. Desalination 107(2):149–157

Papagianni M (2004) Fungal morphology and metabolite production in submerged mycelial processes. Biotechnol Adv 22(3):189–259

Du L-X, Jia S-J, Lu F-P (2003) Morphological changes of Rhizopus chinesis 12 in submerged culture and its relationship with antibiotic production. Process Biochem 38(12):1643–1646

Yang ST, Zhang K, Zhang B, Huang H (2011) Fumaric acid. In: Murray M-Y (ed) Comprehensive biotechnology, 2nd edn. Elsevier, Waltham, pp 163–177

Schrickx JM, Stouthamer AH, Van Verseveld HW (1995) Growth behavior and glucoamylase production by Aspergillus niger N402 and a glucoamylase overproducing transformant in recycling culture without a nitrogen source. Appl Microbiol Biotechnol 43(1):109–116

Ding Y, Li S, Dou C, Yu Y, Huang H (2011) Production of fumaric acid by Rhizopus oryzae: role of carbon–nitrogen ratio. Appl Biochem Biotechnol 164(8):1461–1467

Maas RH, Springer J, Eggink G, Weusthuis RA (2008) Xylose metabolism in the fungus Rhizopus oryzae: effect of growth and respiration on L (+)-lactic acid production. J Ind Microbiol Biotechnol 35(6):569–578

Swinnen IAM, Bernaerts K, Dens EJ, Geeraerd AH, Van Impe JF (2004) Predictive modelling of the microbial lag phase: a review. Int J Food Microbiol 94(2):137–159

Maas RH, Bakker RR, Eggink G, Weusthuis RA (2006) Lactic acid production from xylose by the fungus Rhizopus oryzae. Appl Microbiol Biotechnol 72(5):861–868

Kautola H, Linko Y-Y (1989) Fumaric acid production from xylose by immobilized Rhizopus arrhizus cells. Appl Microbiol Biotechnol 31(5):448–452

Acknowledgements

The authors would like to thank Ms. Chardcie Verret from the Audubon Sugar Institute at Louisiana State University Agricultural Center for her analytical support. USDA-NIFA Award No.: 2011-69005-30515z.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

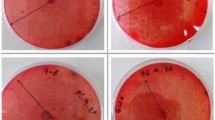

Fig. A1

Morphologies of Rhizopus oryzae ATCC® 20344™ cells grown under different seed culture media conditions (nitrogen source and medium pH). (a) urea at pH 3.0, (b) yeast extract at pH 3.0, (c) urea at pH 4.0, (d) yeast extract at 4.0, (e) urea at pH 5.0, and (f) yeast extract at 5.0. (GIF 1088 kb)

Fig. A2

Rhizopus oryzae ATCC® 20344™ cells grown on seed culture medium containing lignocellulosic syrup as the carbon source. (JPEG 310 kb)

Rights and permissions

About this article

Cite this article

Deng, F., Aita, G.M. Fumaric Acid Production by Rhizopus oryzae ATCC® 20344™ from Lignocellulosic Syrup. Bioenerg. Res. 11, 330–340 (2018). https://doi.org/10.1007/s12155-018-9899-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-018-9899-y