Abstract

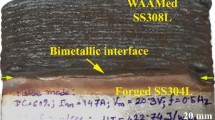

Bimetallic additive manufactured materials replace traditionally manufactured surfaces. Due to the accumulation of excessive heat input during the layer-wise deposition in the Gas Metal Arc based Wire Arc Additive Manufacturing (GMA-WAAM), there is a necessity to analyse the consequences of heat input on microstructural and mechanical properties. The present work deals with the preparation of a bimetallic additive manufactured surface, using hybrid manufactured technology, with a combination of metal forming and wire arc additive manufacturing technology. The present study implemented a variable heat input method for each deposited layer during the WAAM process. SS304L hot forged specimen was taken as substrate material and ER308L wire spool was used for the deposition with pulse mode. During the deposition process, the heat input was varied for each layer. Robot Studio software was used to provide the required heat input for deposition. This provides the best integration between the welding equipment and robot controller, superior path performance and accurate calibration. The microstructure of various layers, mechanical properties, and corrosion rate were studied and found that the hybrid manufacturing technology with variable heat input revealed good results.

Similar content being viewed by others

References

Cheepu, M., Lee, C.I., Cho, S.M.: Microstructural characteristics of wire arc additive manufacturing with Inconel 625 by super-TIG welding. Trans. Indian Inst. Met. 73, 1475–1479 (2020)

Chigilipalli, B.K., Veeramani, A.: Investigation of microstructural properties and mechanical behavior of wire arc additively manufactured incoloy 825. J. Mater. Eng. Perform. 21, 1–6 (2023)

Cheepu, M.: Machine learning approach for the prediction of defect characteristics in wire arc additive manufacturing. Trans. Indian Inst. Met. 76(2), 447–455 (2023)

Chigilipalli, B.K., Veeramani, A.: Investigation of the corrosion behavior of wire arc additively manufactured alloy 825. Trans. Indian Inst. Met. 76(2), 279–286 (2023)

Chigilipalli, B.K., Veeramani, A.: Investigations on dry sliding wear behavior of a wire arc additively manufactured nickel-based superalloy. Tribol. Trans. 65(5), 912–923 (2022)

Ding, D., Pan, Z., Cuiuri, D., Li, H.: Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 81, 465–481 (2015)

Kumar, C.B., Anandakrishnan, V.: Experimental investigations on the effect of wire arc additive manufacturing process parameters on the layer geometry of Inconel 825. Mater. Today Proc. 21, 622–627 (2020)

Sarila, V.K., Moinuddin, S.Q., Cheepu, M., Rajendran, H., Kantumuchu, V.C.: Characterization of microstructural anisotropy in 17–4 PH stainless steel fabricated by DMLS additive manufacturing and laser shot peening. Trans. Indian Inst. Met. 76(2), 403–410 (2023)

Chigilipalli, B.K., Karri, T., Chetti, S.N., Bhiogade, G., Kottala, R.K., Cheepu, M.: A review on recent trends and applications of IoT in additive manufacturing. Appl. Syst. Innov. 6(2), 50 (2023)

Cunningham, C.R., Flynn, J.M., Shokrani, A., Dhokia, V., Newman, S.T.: Invited review article: strategies and processes for high-quality wire arc additive manufacturing. Addit. Manuf. 22, 672–686 (2018)

Lee, J.M., Cheepu, M., Chung, H.: Experiment-based distortion prediction model for wire-based additive manufactured parts. J. Mech. Sci. Technol. 36(12), 6227–6237 (2022)

Srivastava, S., Garg, R.K., Sharma, V.S., Sachdeva, A.: Measurement and mitigation of residual stress in wire-arc additive manufacturing: a review of macro-scale continuum modelling approach. Arch. Comput. Methods Eng. 28(5), 3491–3515 (2020)

Ainapurapu, S.B., Rama Sastry, D.V.A., Ram Prabhu, T.: Experimental investigation and process parameter optimization in cold metal transfer welding for SS304L using response surface method. Eng. Res. Express. 5(1), 015076–6 (2023)

Ainapurapu, S.B., RamaSastry, D.V.A., Ram Prabhu, T.: A hybrid approach consisting of multi-objective and multivariate analyses for WAAM specimens. Eng. Res. Express 5(2) (2023)

Cheepu, M., Baek, H.J., Kim, Y.S., Cho, S.M.: Penetration estimation of GTAW with C-TYPE FILLER BY NET HEAT INPUT RATIO. Weld. J. 101, 240s-s248 (2022)

Lee, S.H.: CMT-based wire arc additive manufacturing using 316L stainless steel: effect of heat accumulation on the multi-layer deposits. Metals. 10(2), 278 (2020)

Cheepu, M., Kumar Reddy, Y.A., Indumathi, S., Venkateswarlu, D.: Laser welding of dissimilar alloys between high tensile steel and Inconel alloy for high temperature applications. Adv. Mater. Process. Technol. 8(2), 1197–1208 (2022)

Wu, B., Pan, Z., Ding, D., Cuiuri, D., Li, H.: Effects of heat accumulation on microstructure and mechanical properties of Ti6Al4V alloy deposited by wire arc additive manufacturing. Addit. Manuf. 23, 151–160 (2018)

Huang, Y., Ansari, M., Asgari, H., Farshidianfar, M.H., Sarker, D., Khamesee, M.B., et al.: Rapid prediction of real-time thermal characteristics, solidification parameters and microstructure in laser directed energy deposition (powder-fed additive manufacturing). J. Mater. Process. Technol. 274, 116286–6 (2019)

Srivastava, S., Garg, R.K., Sachdeva, A., Sharma, V.S.: A multi-tier layer-wise thermal management study for long-scale wire-arc additive manufacturing. J. Mater. Process. Technol. 306, 117651 (2022)

Jiang, W.C., Wang, B.Y., Gong, J.M., Tu, S.T.: Finite element analysis of the effect of welding heat input and layer number on residual stress in repair welds for a stainless-steel clad plate. Mater. Des. 32(5), 2851–2857 (2011)

Cheepu, M., Haribabu, S., Ramachandraiah, T., Srinivas, B., Venkateswarulu, D., Karna, S., Alapati, S., Che, W.S.: Fabrication and analysis of accumulative roll bonding process between magnesium and aluminum multi-layers. Appl. Mech. Mater. 15(877), 183–189 (2018)

Bambach, M., Sizova, I., Sydow, B., Hemes, S., Meiners, F.: Hybrid manufacturing of components from Ti-6Al-4V by metal forming and wire-arc additive manufacturing. J. Mater. Process. Technol. 282, 116689 (2020)

Elmer, J.W., Fisher, K., Gibbs, G., Sengthay, J., Urabe, D.: Post-build thermomechanical processing of wire arc additively manufactured stainless steel for improved mechanical properties and reduction of crystallographic texture. Addit. Manuf. 50, 102573 (2022)

Merklein, M., Schulte, R., Papke, T.: An innovative process combination of additive manufacturing and sheet bulk metal forming for manufacturing a functional hybrid part. J. Mater. Process. Technol. 291, 117032 (2021)

Meiners, F., Ihne, J., Jürgens, P., Hemes, S., Mathes, M., Sizova, I., Bambach, M., Hama-Saleh, R., Weisheit, A.: New hybrid manufacturing routes combining forging and additive manufacturing to efficiently produce high-performance components from Ti-6Al-4V. Procedia Manuf. 47, 261–267 (2020)

Jafari, D., Vaneker, T.H.J., Gibson, I.: Wire and arc additive manufacturing: opportunities and challenges to control the quality and accuracy of manufactured parts. Mater. Des. 202, 109471 (2021)

Chigilipalli, B.K., Veeramani, A.: An experimental investigation and neuro-fuzzy modeling to ascertain metal deposition parameters for the wire arc additive manufacturing of Incoloy 825. CIRP J. Manuf. Sci. Technol. 38, 386–400 (2022)

Anuradha, M., Das, V.C., Susila, P., Cheepu, M., Venkateswarlu, D.: Effect of welding parameters on TIG welding of Inconel 718 to AISI 4140 steel. Trans. Indian Inst. Met. 73, 1515–1520 (2020)

Cheepu, M., Che, W.S.: Influence of friction pressure on microstructure and joining phenomena of dissimilar joints. Trans. Indian Inst. Met. 73, 1455–1460 (2020)

Switzner, N.T., Sawyer, E.T., Everhart, W.A., Hanlin, R.L.: Predicting microstructure and strength for AISI 304L stainless steel forgings. Mater. Sci. Eng. A 745, 474–483 (2019)

Le, V.T., Mai, D.S., Doan, T.K., Paris, H.: Wire and arc additive manufacturing of 308L stainless steel components: optimization of processing parameters and material properties. Eng. Sci. Technol. Int. J. 24(4), 1015–1026 (2021)

Ainapurapu, S.B., Devulapalli, V.A., Theagarajan, R.P., Chigilipalli, B.K., Kottala, R.K., Cheepu, M.: Microstructure and mechanical properties of the bimetallic wire arc additively manufactured structure (BAMS) of SS304L and SS308L fabricated by hybrid manufacturing process. Trans. Indian Inst. Met. 76(2), 419–426 (2023)

Dávila, J.L., Neto, P.I., Noritomi, P.Y., Coelho, R.T., da Silva, J.V.L.: Hybrid manufacturing: a review of the synergy between directed energy deposition and subtractive processes. Int. J. Adv. Manuf. Technol. 110(11–12), 3377–3390 (2020)

Hertzman, S., Brolund, B., Ferreira, P.J.: An experimental and theoretical study of heat-affected zone austenite reformation in three duplex stainless steels. Metall. and Mater. Trans. A. 28(2), 277–285 (1997)

Allain, S., Aoued, S., Quintin-Poulon, A., Gouné, M., Danoix, F., Hell, J.C., et al.: In situ investigation of the iron carbide precipitation process in a Fe-C-Mn-Si Q&P steel. Materials. 11(7), 1087 (2018)

Weiss, B., Stickler, R.: Phase instabilities during high temperature exposure of 316 austenitic stainless steel. Metall. Mater. Trans. B 3, 851–866 (1972)

Li, G., Sui, X., Qin, X., Ma, Y., Wang, K., Wang, Q.: Structural transformation between bcc and fcc in Fe–Ni nanoparticle during heating process. Phys. Lett. A 380(42), 3500–3504 (2016)

Dewangan, S., Singhal, P., Selvaraj, S.K., Dev, S.J., Swathish, R.S., Cheepu, M., Legutko, S., Adefris, A., Chattopadhyaya, S., Chadha, U.: Analysing strength, hardness and grain-structure of 0.2%-C steel specimens processed through an identical heating period with different continuous transformation rates. Mater. Res. Express 9(12), 126505 (2022)

Babu, K.T., Muthukumaran, S., Kumar, C.B., Narayanan, C.S.: Improvement in mechanical and metallurgical properties of friction stir welded 6061-t6 aluminum alloys through cryogenic treatment. In: Materials Science Forum 2019 Oct 30 (Vol. 969, pp. 490–495). Trans Tech Publications Ltd

Yin, Y.J., Sun, J.Q., Guo, J., Kan, X.F., Yang, D.C.: Mechanism of high yield strength and yield ratio of 316 L stainless steel by additive manufacturing. Mater. Sci. Eng. A 744, 773–777 (2019)

Aydın, H., Bayram, A., Uğuz, A., Akay, K.S.: Tensile properties of friction stir welded joints of 2024 aluminum alloys in different heat-treated-state. Mater. Des. 30(6), 2211–2221 (2009)

Anuradha, M., Das, V.C., Venkateswarlu, D., Cheepu, M.: Microstructure characterization in dissimilar TIG welds of Inconel alloy 718 and high strength tensile steel. In: Materials Science Forum 2019 Oct 30 (Vol. 969, pp. 496–501). Trans Tech Publications Ltd

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhadrakali, A.S., Sastry, D.V.A.R., Chigilipalli, B.K. et al. Effect of heat input on microstructure and mechanical properties of bimetallic wire arc additive manufacturing of SS304L and ER308L prepared by hybrid manufacturing process. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01662-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01662-5