Abstract

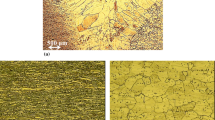

17-4 precipitation-hardenable stainless steel (17-4PH SS) finds essential applications in aerospace, chemical processing, and in oil and petroleum industries. The studies related to friction welding on selective laser melted (SLM) components are limited and depend on the material chosen. The present study aims to understand the friction welding of similar 17-4 PH SS fabricated by the SLM technique. X-ray diffraction analysis confirms the presence of austenitic and martensitic phases in both the base metal (BM) and the weld zone (WZ). Due to dynamic recrystallization, the microstructural changes are observed with columnar grains in the BM to refined equiaxed grains in the WZ. The homogenous microstructure is reflected in the hardness measurements of the WZ showing a uniform hardness distribution. Hardness at the WZ is decreased by about 17% than the BM. Corrosion studies through potentio dynamic polarisation analysis reveal that the BM is nobler towards corrosion than the WZ and wrought material. This study would pave the way for future studies on dissimilar weld joint analysis involving 17-4 PH SS.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available upon reasonable request.

References

Hu, Z., Zhu, H., Zhang, H., Zeng, X.: Experimental investigation on selective laser melting of 17-4PH stainless steel. Opt. Laser Technol. 87, 17–25 (2017). https://doi.org/10.1016/j.optlastec.2016.07.012

Sokkalingam, R., Sivaprasad, K., Singh, N., et al.: Subtle change in the work hardening behavior of FCC materials processed by selective laser melting. Prog. Addit. Manuf. 7, 453–461 (2022). https://doi.org/10.1007/s40964-022-00301-x

Gokuldoss, P.K., Kolla, S., Eckert, J.: Additive manufacturing processes: selective laser melting, electron beam melting and binder jetting—selection guidelines. Materials (Basel) 10, 672 (2017). https://doi.org/10.3390/ma10060672

Prashanth, K.G., Scudino, S., Klauss, H.J., et al.: Microstructure and mechanical properties of Al–12Si produced by selective laser melting: effect of heat treatment. Mater. Sci. Eng. A 590, 153–160 (2014). https://doi.org/10.1016/j.msea.2013.10.023

Kumar, D.P., Kumaran, S.: Evaluating the microstructural, mechanical, and electrochemical behavior of spark plasma-assisted dissimilar joining of 17-4 PH stainless steel to Inconel 718. J. Mater. Eng. Perform. (2022). https://doi.org/10.1007/s11665-022-07691-7

Feng, B., Deng, Y., Feng, X., et al.: Interfacial reaction and mechanical properties of diffusion bonded titanium/17-4 PH stainless steel dissimilar joint using a silver interlayer. Mater. Res. Express 7, 116518 (2020). https://doi.org/10.1088/2053-1591/abc910

Borchers, T.E., Hahn, M.E., Lowiec, B.A., Tung, D.J.: Dissimilar GTAW Stainless Steel Welding. (Poster- Ohio state univ) 304

Li, W., Vairis, A., Preuss, M., Ma, T.: Linear and rotary friction welding review. Int. Mater. Rev. 61, 71–100 (2016). https://doi.org/10.1080/09506608.2015.1109214

Muralimohan, C.H., Ashfaq, M., Ashiri, R., et al.: Analysis and characterization of the role of Ni interlayer in the friction welding of titanium and 304 austenitic stainless steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 47, 347–359 (2016). https://doi.org/10.1007/s11661-015-3210-z

Muralimohan, C.H., Haribabu, S., Reddy, Y.H., et al.: Evaluation of microstructures and mechanical properties of dissimilar materials by friction welding. Procedia Mater. Sci. 5, 1107–1113 (2014). https://doi.org/10.1016/j.mspro.2014.07.404

Garcia-Cabezon, C., Castro-Sastre, M.A., Fernandez-Abia, A.I., et al.: Microstructure–hardness–corrosion performance of 17-4 precipitation hardening stainless steels processed by selective laser melting in comparison with commercial alloy. Met. Mater. Int.. Mater. Int. 28, 2652–2667 (2022). https://doi.org/10.1007/s12540-021-01155-8

Stoudt, M.R., Ricker, R.E., Lass, E.A., Levine, L.E.: Influence of postbuild microstructure on the electrochemical behavior of additively manufactured 17-4 PH stainless steel. JOM 69, 506–515 (2017). https://doi.org/10.1007/s11837-016-2237-y

Ko, G., Kim, W., Kwon, K., Lee, T.-K.: The corrosion of stainless steel made by additive manufacturing: a review. Metals (Basel) 11, 516 (2021). https://doi.org/10.3390/met11030516

Schaller, R.F., Taylor, J.M., Rodelas, J., Schindelholz, E.J.: Corrosion properties of powder bed fusion additively manufactured 17-4 PH stainless steel. Corrosion 73, 796–807 (2017). https://doi.org/10.5006/2365

Alnajjar, M.: Corrosion properties of 17-4 PH martensitic stainless steel obtained by additive manufacturing. (Thesis) (2020)

Chigilipalli, B.K., Veeramani, A.: Investigation of the corrosion behavior of wire arc additively manufactured alloy 825. Trans. Indian Inst. Met. 76, 279–286 (2023). https://doi.org/10.1007/s12666-022-02656-9

Prashanth, K.G., Damodaram, R., Scudino, S., et al.: Friction welding of Al-12Si parts produced by selective laser melting. Mater. Des. 57, 632–637 (2014). https://doi.org/10.1016/j.matdes.2014.01.026

Prashanth, K.G., Damodaram, R., Maity, T., et al.: Friction welding of selective laser melted Ti6Al4V parts. Mater. Sci. Eng. A 704, 66–71 (2017). https://doi.org/10.1016/j.msea.2017.08.004

Zhao, Z., Wang, H., Huo, P., et al.: Effect of Solution temperature on the microstructure and properties of 17-4PH high-strength steel samples formed by selective laser melting. Metals (Basel) 12, 425 (2022). https://doi.org/10.3390/met12030425

Kotecki, D.J., Siewert, T.A.: WRC-1992 Constitution diagram for stainless steel weld metals: a modification of the WRC-1988 Diagram. In: AWS Annu Meet, pp 171–178 (1992)

Nowacki, J.: Weldability of 17-4 PH stainless steel in centrifugal compressor impeller applications. J. Mater. Process. Technol. 157–158, 578–583 (2004). https://doi.org/10.1016/j.jmatprotec.2004.07.117

Zai, L., Zhang, C., Wang, Y., et al.: Laser powder bed fusion of precipitation-hardened martensitic stainless steels: a review. Metals (Basel) 10, 255 (2020). https://doi.org/10.3390/met10020255

Ziewiec, A., ZieliŃska-Lipiec, A., Tasak, E.: Microstructure of welded joints of X5CrNiCuNb16-4 (17-4 PH) martensitic stainlees steel after heat treatment. Arch. Metall. Mater. 59, 965–970 (2014). https://doi.org/10.2478/amm-2014-0162

Schmuki, P., Hildebrand, H., Friedrich, A., Virtanen, S.: The composition of the boundary region of MnS inclusions in stainless steel and its relevance in triggering pitting corrosion. Corros. Sci.. Sci. 47, 1239–1250 (2005). https://doi.org/10.1016/j.corsci.2004.05.023

Yang, S., Zhao, M., Feng, J., et al.: Induced-pitting behaviors of MnS inclusions in steel. High Temp. Mater. Process. 37, 1007–1016 (2018). https://doi.org/10.1515/htmp-2017-0155

Li, N., Yan, H., Wang, X., et al.: Effect of copper on microstructure and corrosion resistance of hot rolled 301 stainless steel. Metals (Basel) 13, 170 (2023). https://doi.org/10.3390/met13010170

Park, S.H.C., Sato, Y.S., Kokawa, H., et al.: Corrosion resistance of friction stir welded 304 stainless steel. Scr. Mater. 51, 101–105 (2004). https://doi.org/10.1016/j.scriptamat.2004.04.001

Raja, K.S., Rao, K.P.: Pitting behavior of type 17-4 PH stainless steel weldments. Corrosion 51, 586–592 (1995). https://doi.org/10.5006/1.3293618

Raja, K.S., Prasad Rao, K.: Intergranular and general corrosion behaviour of 17-4 PH weldments. Mater. Corros.Corros. 46, 534–538 (1995). https://doi.org/10.1002/maco.19950460905

Acknowledgements

The authors thank the SPARC program (SPARC/2018-2019/P361/SL) from the Ministry of Human Resources and Development (MHRD), Government of India, for the financial support. Funding from the European scholarship (Dora plus) is greatly acknowledged.

Author information

Authors and Affiliations

Contributions

LD: Methodology, Data Curation, Validation, Formal Analysis, Investigation, Writing – original draft preparation. RNK: Data Curation, Formal Analysis, Investigation, Writing – original draft preparation. KGP: Validation, Writing – Reviewing and Editing, Resources, Supervision. KS: Conceptualization, Validation, Writing – Reviewing and Editing, Resources, Supervision, Funding Acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dinesh, L., Nitheesh Kumar, R., Prashanth, K.G. et al. Electrochemical analysis of friction welded 17-4 PH stainless steel components manufactured by selective laser melting. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01659-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01659-0