Abstract

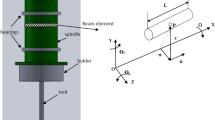

This paper presents an optimum design approach of spindle-tool system for improvising the dynamic stability of cutting process. Prediction of dynamic behaviour at the tool tip is necessary in assessing the machining stability of a machine tool during design stage. Spindle-tool assembly is initially analysed by using finite element analysis with Timoshenko beam elements and tool-tip frequency response functions are obtained. In order to maximize the chatter-free region in the stability lobe diagram, an optimization study is carried-out by considering spindle parameters such as bearing locations on spindle shaft along with tool-overhang as design variables. A simulated experimental dynamic data consisting of natural frequencies and average stable depth of cut is obtained for different combinations of tool overhang and bearing span values. Based on the obtained results, the data is generalized using a feed-forward neural network model which is employed to estimate the average stable depths for the optimization module. A global meta-heuristic optimization scheme namely genetic algorithm is employed to achieve the spindle design data corresponding to maximum average stable depth of cut and it is validated with. End-milling experiments are carried-out to validate the stability states corresponding to various axial depths of cut.

Similar content being viewed by others

Data availability

All data underlying the results is available as part of the article and no additional source data is required.

References

Altintas, Y., Budak, E.: Analytical prediction of stability lobes in milling. Ann. CIRP 44, 357–362 (1995)

Altintas, Y., Weck, M.: Chatter Stability of Metal Cutting and Grinding. CIRP Ann. Manf. Tech. 53, 619–642 (2004)

Bravo, U., Altuzarra, O., Lopez de Lacalle, L.N., Sanchez, J.A., Campa, F.J.: Stability limits of milling considering the flexibility of the workpiece and the machine. Int. J. Mach. Tools Manf. 45, 1669–1680 (2005)

Gagnola, V., Bouzgarrou, B.C., Raya, P., Barra, C.: Model-based chatter stability prediction for high-speed spindles. Int. J. Mach. Tools Manf. 47, 1176–1186 (2007)

Tanga, W.X., Songa, Q.H.: Prediction of chatter stability in high-speed finishing end Milling considering multi-mode dynamics. Int. J. Mach. Tools Manf. 209, 2585–2591 (2009)

Suzuki, N., Kurata, Y., Kato, T., Hino, R., Shamoto, E.: Identification of transfer function by inverse analysis of self-excited chatter vibration in milling operations. Precis. Eng. 36, 568–575 (2012)

Raphael, G.S., Reginaldo, T.C.: A Contribution to improve the accuracy of chatter prediction in machine tools using the stability lobe diagram. J. Manf. Sci. Eng. ASME 136, 021005–021007 (2014)

Lin, C.W., Tu, J.F.: Model-based design of motorized spindle systems to improve dynamic performance at high speeds. J. Manuf. Process. 9, 94–108 (2007)

Jiang, S., Zheng, S.: Dynamic design of a high-speed motorized spindle-bearing system. J. Mech. Des. ASME 132, 0345011–0345015 (2010)

Penga, Z.K., Jackson, M.R., Guo, L.Z., Parkin, R.M., Meng, G.: Effects of bearing clearance on the chatter stability of milling process. Nonlinear Anal. Real World Appl. 11, 3577–3589 (2010)

Cao, H., Holkup, T., Altintas, Y.: A comparative study on the dynamics of high speed spindles with respect to different preload mechanisms. Int. J. Mach. Tools Manf 57, 871–883 (2011)

Gao, S.H., Meng, G.: Research of the spindle over hang and bearing span on the system milling stability. Arch. Appl. Mech. 81, 1473–1486 (2011)

Ozturk, E., Kumar, U., Turner, S., Schmitz, T.: Investigation of spindle bearing preload on dynamics and stability limit in milling. Int. J. Mach. Tools Manf. 61, 343–346 (2012)

Liu, J., Chen, X.: Dynamic design for motorized spindles based on an integrated model. Int. J. Adv. Manuf. Technol. 71, 1961–1974 (2014)

Altintas, Y.: Modeling Approaches and software for predicting the performance of milling operations at Mal-Ubc. Mach. Sci. Technol. Int. J. 4, 3445–3478 (2000)

Jalalli Saffar, R., Razfar, M.R.: Simulation of end milling operation for predicting cutting forces to minimize tool deflection by genetic algorithm. Mach. Sci. Technol. Int. J. 14, 81–101 (2010)

Palanisamy, P., Rajendran, I., Shanmugasundaram, S.: Optimization of machining parameters using genetic algorithm and experimental validation for end-milling operations. Int. J. Adv. Manuf. Technol. 32, 644–655 (2007)

Hsieh, H.T., Chu, C.H.: Improving optimization of tool path planning in 5-axis flank milling using advanced PSO algorithms. Robot. Comput. Integrated Manuf. 29, 3–11 (2013)

Zareia, O., Fesanghary, M., Farshi, B., Saffar, J., Razfar, R.M.R.: Optimization of multi-pass face-milling via harmony search algorithm. J. Mater. Process. Technol. 209, 2386–2392 (2009)

Wang, D., Penter, L., Hänel, A., Steffen, I., Marian, W.: Stability enhancement and chatter suppression in continuous radial immersion milling. Int. J. Mech. Sci. 235, 107711 (2022)

Florian, W., Jim, B., Petra, W.: A systematic approach for data acquisition and analysis of spindle speed-dependent modal parameters. Proc. CIRP 118, 205–210 (2023)

Kaidong, C., He, Z., Nathan, V., Emmanuel, D.: An alternative approach to model the dynamics of a milling tool. J. Sound Vib. 569(20), 117940 (2023)

Cheepu, M., Baek, H.J., Kim, Y.S., Cho, S.M., Melting characteristics of C-type filler metal in GTAW. Weld. J. 102(9), 201–216 (2023). https://doi.org/10.29391/2023.102.016

Cheepu, M., Susila, P.: Growth rate of intermetallics in aluminum to copper dissimilar welding. Trans. Indian Inst. Met. 73, 1509–1514 (2020). https://doi.org/10.1007/s12666-020-01905-z

Muralimohan, C.H., Haribabu, S., Reddy, Y.H., Muthupandi, V., Sivaprasad, K.: Evaluation of microstructures and mechanical properties of dissimilar materials by friction welding. Proc. Mater. Sci. 5, 1107–1113 (2014)

Cho, D.-W., Park, Y.-D., Cheepu, M.: Numerical simulation of slag movement from marangoni flow for GMAW with computational fluid dynamics. Int. Commun. Heat Mass Transf. 125, 105243 (2021)

Cheepu, M., Cheepu, H., Karpagaraj, A., Che, W.S.: Influence of joint interface on mechanical properties in dissimilar friction welds. Adv. Mater. Process. Technol. 8(1), 732–744 (2022). https://doi.org/10.1080/2374068X.2020.1832413

Park, J.H., Cheepu, M., Cho, S.M.: Analysis and Characterization of the weld pool and bead geometry of inconel 625 super-TIG welds. Metals 10, 365 (2020). https://doi.org/10.3390/met10030365

Anuradha, M., Das, V.C., Susila, P., et al.: Effect of welding parameters on TIG welding of inconel 718 to AISI 4140 steel. Trans. Indian Inst. Met. 73, 1515–1520 (2020). https://doi.org/10.1007/s12666-020-01926-8

Cheepu, M., Che, W.S.: Friction welding of titanium to stainless steel using Al interlayer. Trans. Indian Inst. Met. 72, 1563–1568 (2019). https://doi.org/10.1007/s12666-019-01655-7

Cheepu, M., Baek, H.J., Kim, Y.S., Cho, S.M.: Penetration estimation of GTAW with C-type filler by net heat input ratio. Weld. J. 101, 240s–248s (2022)

Cheepu, M.: Machine learning approach for the prediction of defect characteristics in wire arc additive manufacturing. Trans. Indian Inst. Met. 76, 447–455 (2023). https://doi.org/10.1007/s12666-022-02715-1

Ainapurapu, S.B., Devulapalli, V.A., Theagarajan, R.P., Chigilipalli, B.K., Kottala, R.K., Cheepu, M.: Microstructure and mechanical properties of the bimetallic wire arc additively manufactured structure (BAMS) of SS304L and SS308L fabricated by hybrid manufacturing process. Trans. Indian Inst. Met. 76(2), 419–426 (2023)

Kumar, K.R., Balasubramanian, K.R., Kumar, G.P., Bharat Kumar, C., Cheepu, M.M.: Experimental investigation of nano-encapsulated molten salt for medium-temperature thermal storage systems and modeling of neural networks. Int. J. Thermophys. 43(9), 145 (2022). https://doi.org/10.1007/s10765-022-03069-y

Moinuddin, S.Q., Machireddy, V.V., Raghavender, V., Kaniganti, T.B., Sarila, V., Ponnappan, S.M., Shanmugam, R., Cheepu, M.: Analysis on bonding interface during solid state additive manufacturing between 18Cr-8Ni and 42crmo4 high performance alloys. Metals 13(3), 488 (2023). https://doi.org/10.3390/met13030488

Pramod Kumar, G., Balasubramanian, K.R., Phani Prabhakar, K.V., Cheepu, M.: Investigation of microstructure, mechanical, and corrosion properties of Inconel 617 joints welded by laser–MIG hybrid welding. In: Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications (2023). https://doi.org/10.1177/14644207231161992

Kocharla, R.P.B., Kolli, M., Cheepu, M.: Real-time detection of faults in rotating blades using frequency response function analysis. Applied Mechanics 4(1), 356–370 (2023)

Chigilipalli, B.K., Karri, T., Chetti, S.N., Bhiogade, G., Kottala, R.K., Cheepu, M.: A review on recent trends and applications of IoT in additive manufacturing. Appl. Syst. Innov. 6(2), 50 (2023)

Dasari, S.N., Vinjavarapu, S., Cheepu, M.M.: Effect of reinforcement particle size on LM-13-snail shell ash–SiC hybrid metal matrix composite. Waste Residue Comp. 16, 87 (2023)

Dewangan, A.K., Moinuddin, S.Q., Cheepu, M., Sajjan, Ashwani Kumar, S.K.: Thermal energy storage: opportunities, challenges and future scope. Therm. Energy Syst., pp 17–28

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare. All co-authors have seen and agree with the contents of the manuscript and there is no financial interest to report. We certify that the submission is original work and is not under review at any other publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Boddu, J.R., Kotaiah, K.R., Chalapathi, P.V. et al. Optimization of design for the high precision end mill spindles to improve stability of effective cutting process. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01526-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01526-y