Abstract

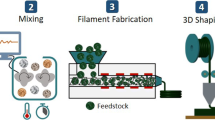

Additive manufacturing is an advanced manufacturing technology to produce components with superior quality, aesthetic shape, less wastage and reduced production time. Fused deposition modeling (FDM) is one of the additive manufacturing techniques adopted by small scale industries as it is most economical and produces compact sized components. Even though, the lack of feedstock (i.e., filament) material leads to increase in overall manufacturing cost. This paper explores design and fabrication of internal mixer (IM) and filament extruder for blending of composite materials, production of polymer filaments and hybrid composite filaments (i.e., polymer filaments with reinforcement of natural fibers) for FDM applications. The polylactic acid polymer, bamboo natural fibers and maleic anhydride compatibilizer are taken as a raw material. The internal mixer has been fabricated successfully is the most economical approach as compared to commercially available IM. The result shows that, the developed IM produces 250 g of blended mixture (i.e., combination of polymers, natural fibers and plasticizers) in a duration of 30 min. Also, the designed and fabricated portable filament extruder tested and extracted continuous polymer and hybrid filaments with a diameter ranging from 1.6 to 2 mm and mass flow rate of 15.6 mm3/s respectively. In addition, the obtained filament having no warping, without clogging, no under and over extrusion, more precise and most economical as compared to existing filament extruders. The developed IM and filament extruder are adequate to small scale vendors and industries.

Access this article

We’re sorry, something doesn't seem to be working properly.

Please try refreshing the page. If that doesn't work, please contact support so we can address the problem.

Similar content being viewed by others

References

Dixit, A.R., Srivastava, A.K., Dwivedi, S., Nag, A., Hloch, S.: An investigation on microstructural features and bonding strength of magnesium-based multifunctional laminated composite developed by friction stir additive manufacturing. Int. J. Adv. Manuf. Technol. 128, 531–546 (2023)

Davim, J.P.: Additive and Subtractive Manufacturing. Aveiro, Portugal (2020)

Mpofu, T.P., Mawere, C., Mukosera, M.: The impact and application of 3D printing technology. Int. J. Sci. Res. 3, 2148–2152 (2014)

Elakkad, A.S.: 3D Technology in the automotive industry. Int. J. Eng. Res. Technol. 8, 277–308 (2019)

Adin, M.S., Batman Kılıçkap, E.: Strength of double-reinforced adhesive joints. Mater. Tes. 63(2), 176–181 (2021)

Manjaiah, M., Raghavendra, K., Balashanmugam, N., Davim, J.P.: Additive manufacturing. In: A Tool for Industrial Revolution 4.0, Elsevier (2021)

Sai Kalyan, M.V., Kumar, H., Nagdeve, L.: Latest trends in additive manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 1104, 012020 (2021)

Wong, K.V., Hernandez, A.: A review of additive manufacturing. ISRN Mech. Eng. 2012, 1–10 (2012)

Jiménez, M., Romero, L., Domínguez, I.: Additive manufacturing technologies: an overview about 3D printing methods and future prospects. Complexity 2019, 1–30 (2019)

Sehrawat, S., Kumar, A., Prabhakar, M., Nindra, J.: The expanding domains of 3D printing pertaining to the speciality of orthodontics. Mater. Today Proc. 50, 1611–1618 (2022)

Shashi, G.M., Laskar, A.R., Biswas, H.: A brief review of additive manufacturing with applications. In: Proceedings of the 14th Global Engineering and Technology Conference 2017, pp. 1–23 (2017)

Pradeepkumar, C., Karthikeyan, S., Rajini, N., Budholiya, S., Raj, S.A.: A contemporary review on additive manufactured biomedical implants. Mater. Today Proc. 46, 8812–8816 (2021)

Pou, J., Riveiro, A., Davim, J.P.: Additive Manufacturing. Elsevier, New York (2021)

Bertolino, M., Battegazzore, D., Arrigo, R., Frache, A.: Designing 3D printablepolypropylene: material and process optimisation through rheology. Addit. Manuf. 40, 101944 (2021)

Zhang, Z., Gao, X.: Polypropylene random copolymer based composite used for fused filament fabrication: printability and properties. Polymers 14(6), 1106 (2022)

Samykano, M., Selvamani, S.K., Kadirgama, K., Ngui, W.K., Kanagaraj, G., Sudhakar, K.: Mechanical property of FDM printed ABS: influence of printing parameters. Int. J. Adv. Manuf. Technol. 102(9–12), 2779–2796 (2019)

Wichniarek, R., Hamrol, A., Kuczko, W., Górski, F., Rogalewicz, M.: ABS filament moisture compensation possibilities in the FDM process. CIRP J. Manuf. Sci. Technol. 35, 550–559 (2021)

Kumar, A., Mittal, R.K., Haleem, A.: Advances in Additive Manufacturing: Artificial Intelligence, Nature-Inspired, and Biomanufacturing. Elesevier, New York (2022)

Yao, T., Deng, Z., Zhang, K., Li, S.: A method to predict the ultimate tensile strength of 3D printing polylactic acid (PLA) materials with different printing orientations. Compos. Part B Eng. 2019(163), 393–402 (2019)

Wach, R.A., Wolszczak, P., Wlodarczyk, A.A.: Enhancement of mechanical properties of FDM-PLA parts via thermal annealing. Macromol. Mater. Eng. 303(9), 1–9 (2018)

Holbery, J., Houston, D.: Natural-fiber-reinforced polymer composites in automotive applications. Jom 58(11), 80–86 (2006)

Adin, H., Şükrü, M.A.: Effect of particles on tensile and bending properties of jute epoxy composites. Materia Test. 64(3), 401–411 (2022)

Gholampour, A., Ozbakkaloglu, T.: A review of natural fiber composites: properties, modification and processing techniques, characterization. Appl. J. Mater. Sci. 55, 829–892 (2020)

Milosevic, M., Stoof, D., Pickering, K.L.: Characterizing the mechanical properties of fused deposition modelling natural fiber recycled polypropylene composites. J. Compos. Sci. 1(1), 1–7 (2017)

Ahmad, M.N., Wahid, M.K., Maidin, N.A., Rahman, M.H.A.: Mechanical characteristics of oil palm fiber reinforced thermoplastics as filament for fused deposition modeling (FDM). Int. J. Adv. Manuf. Technol. 8, 1–13 (2020)

Tekinalp, H.L., Kunc, V., Velez-Garcia, G.M., Duty, C.E., Love, L.J., Naskar, A.K., Blue, C.A., Ozcan, S.: Highly oriented carbon fiber-polymer composites via additive manufacturing. Compos. Sci. Technol. 105, 144–150 (2014)

Orisaleye, J.I., Adefuye, O.A., Ogundare, A.A., Fadipe, O.L.: Parametric analysis and design of a screw extruder for slightly Non-Newtonian (pseudoplastic) materials. Eng. Sci. Technol. Int. J. 21(2), 229–237 (2018)

Harimalairajan, K., Sadhananthan, S.M.: Development of plastic filament extruder for 3D-printing. Int. J. Mech. Prod. Eng. 4, 32–35 (2016)

Aminur, M., Zainal, I., Mat, S., Sam, M.S., Faiz, R., Alkahari, M.R., Kudus, S.I.A.: Design and development of 3D printer filament extruder. Proc. Mech. Eng. Res 2020, 293–294 (2020)

Nassar, A., Nassar, E., Younis, M.: A novel design to external filament extruder for 3D printer. Aust. J. Mech. Eng. 00, 1–8 (2019)

Nassar, M.A., El Farahaty, M.A., Ibrahim, S., Hassan, Y.R.: Design of 3D filament extruder for fused deposition modeling (FDM) additive manufacturing. Int. Des J. 9(4), 55–62 (2014)

David, M.W., Jonathan, K.P.: Design and fabrication of a low-cost pilot-scale melt-processing system. Polymers 181, 121802 (2019)

Hemlata, P., Roshan, V.T., Michael, A.R.: Hot-melt extrusion: from theory to application in pharmaceutical formulation. AAPS Pharm. Sci. Tech. 17(1), 20–42 (2016)

Sathish Kumar, A., Jagadish: Prospects of natural fiber-reinforced polymer composites for additive manufacturing applications : a review. Jom 75, 920–940 (2023)

Jailani, N., Ibrahim, A.N.H., Rahim, A., Abdul Hassan, N., Nur, N.I.: Chemical and physical properties of poly (lactic) acid modified bitumen. Ain Shams Eng. J. 12(3), 2631–2642 (2021)

Andersen, P., Shih, C.K., Spalding, M.A., Wetzel, M.D., Womer, T.W.: Breakthrough inventions in polymer extrusion. SPE ANTECH 55, 668–677 (2009)

Mikulionok, I., Gavva, O., Kryvoplias-Volodina, L.: Modeling the process of polymers processing in twinscrew extruders. East. Eur. J. Enterp. Technol. 4(5–94), 35–44 (2018)

Sang, L., Han, S., Li, Z., Yang, X., Hou, W.: Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. Part B Eng. 164, 629–639 (2019)

Adin, H., Yıldız, B., Adin, M.S.: Numerical Investigation of Fatigue behaviors of non-patched and patched aluminum pipes. Eur. J. Tech. 11(1), 60–65 (2021)

Woern, A.L., Mccaslin, J.R., Pringle, A.M., Pearce, J.M.: RepRapable Recyclebot: open source 3-D printable extruder for converting plastic to 3-D printing filament. HardwareX 4, E00026 (2018)

Roshchupkin, S.I., Golovin, V.I., Kolesov, A.G., Tarakhovskiy, A.Y.: Extruder for the production of metal-polymer filament for additive technologies. Mater. Sci. Eng. 971, 1–6 (2020)

Shaik, Y.P., Schuster, J., Shaik, A.: A scientific review on various pellet extruders used in 3D printing FDM processes. Ope Access Libr. J. 8, 1–19 (2021)

Priya, N., Kumar, S.N., Kumar, S.P., Pradeep, K.K.: Design and fabrication of filament extruder with spooler. Mater. Today Proc. 81(2), 221–223 (2023)

Isa, N.M.A., Sa, N., Ibrahim, M.I.: Verificaton of feed rate effects on filament extrusion for freeform fabrication. ARPN J. Eng. Appl. Sci. 11(10), 6556–6561 (2016)

Sasmitha, S.S., Uma, R.N.: A critical review on the application of bakelite as a partial replacement of fine and coarse aggregate. Int. J. Sci. Res. Dev. 4(11), 174–178 (2018)

Adin, H., Saglam, Z., Adin, M.S.: Numerical investigation of fatigue behavior of non-patched and patched aluminum/composite plates. Eur. Mech. Sci. 5(4), 168–176 (2021)

Martin, C.: Twin screw extruders as continuous mixers for thermal processing: a technical and historical perspective. AAPS Pharm. Sci. Tech. 17(1), 3–19 (2016)

Marinho, V.A.D., Cesario, L.V., Costa, A.R.M., Carvalho, L.H., Almeida, T.G., Canedo, E.L.: Heat transfer coefficient in internal mixers for different polymers and processing conditions. Chem. Eng. Res. Des. 1–20 (2019)

Kumar, A., Kumar, P., Mittal, R.V., Gambhir, V.: Materials processed by additive manufacturing techniques. In: Advances in Additive Manufacturing: Artificial Intelligence, Nature-Inspired,and Biomanufacturing, pp. 217–233, Elesevier (2023)

Litauszki, K., Petreny, R., Haramia, Z., Meszaros, L.: Combined effects of plasticizers and D-lactide content on the mechanical and morphological behavior of polylactic acid. Heliyon 9, 1–9 (2023)

Akindele, O.E., Kurian, T., Gopi, U.: Effect of sequence of mixing and internal mixer parameters on the viscosity of compounds for tire components. Int. J. Interdisp. Res. Innov. 7(1), 497–503 (2019)

Paul, U.A., Martins, O.A., Eddy, A.O.: The design and construction of a single screw extruder. J. Multidiscip. Eng. Sci. Technol. 6(7), 10340–10349 (2019)

Saliakas, S., Damilo, S., Karamitrou, M., Trompeta, A.F., Milickovic, T.K., Charitidis, C., Koumoulos, E.K.: Integrating exposure assessment and process hazard analysis: the nano-enabled 3D printing filament extrusion case. Polymers 15, 1–21 (2023)

Sadhya, S., Goyal, K.K., Singh, G., Singh, J., Akula, V.S.R.P.: Development of lab-scale extruder to produce feedstock filament for 3D printing using recycled thermoplastics. Mater. Tody. Proc. 80(1), 150–155 (2023)

Dave, H.K., Davim, J.P.: Fused Deposition Modeling Based 3D Printing. Springer, Berlin (2021)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This work does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adapa, S.K., Jagadish Design and fabrication of internal mixer and filament extruder for extraction of hybrid filament composite for FDM applications. Int J Interact Des Manuf 18, 419–432 (2024). https://doi.org/10.1007/s12008-023-01521-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-023-01521-3