Abstract

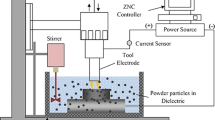

In today's industrial practice, automobilesectors,aviation,military and missile applications aluminium alloys are being widely used material instead of steel because of its light weight and high strength to weight ratio, but it possesses very low wear resistance. To enhance thewear resistance ofaluminumalloysurface modification required.Electrical discharge coating (EDC)one of the surface modification process carried out in the existing electrical discharge machining (EDM) with reverse polarity and powder metallurgy electrode. Hence in the present work, coating of 7075aluminium alloy has been coated with WC/Ni semi-sintered electrode to improve surface properties due to its lower wear resistance during higher load applications. Experiments are percformed based on DOE the study effect of the individual parametersparameters (compaction load, current and pulse on time) on the responses such as micro hardness and surface roughness. The experimental results are verified and justified using ANOVA and revealed that pulse on time has most significant parameter followed by current and compaction laod. However the coating performance are conflict in nature hence there is a need to identify the optimal coating parameters to achieve the desired coating characteristics. Finally, RSM method is adopted for optimization of EDCto identified the optimal coating parameters. Confirmation tests are performed on at predicted optimum process parameters and results are verified. Further, SEM was used to determine the surface morphologyand EDS is used to validate the confirm the alloying of electrode materials on the surface of Al alloy.

Similar content being viewed by others

References

Maddu, J.R., Karrolla, B., Shaik, S.V.R.U.: Formation and optimization of electrical discharge coatings using conventional electrodes. Energy 14, 5691–5710 (2021)

Tijo, D., Kumari, S., Masanta, M.: Hard and wear resistance TiC-composite coating on AISI 1020 steel using powder metallurgy tool by electro-discharge coating process. J Braz. Soc. Mech. Sci. Eng. 39, 4719–4734 (2017)

Sarmah, A., Kar, S., Patowari, P.K.: Surface modification of aluminum with green compact powder metallurgy Inconel-aluminum tool in EDM. Mat. Manuf. Proces 35, 1104–1112 (2020)

Ahmed, Afzaal: Deposition and Analysis of Composite Coating on Aluminum Using Ti–B4C Powder Metallurgy Tools in EDM. Mat. Manuf. Proces. 31, 467–474 (2016)

Eswara Krishna, M., Patowari, P.K.: Parametric study of electric discharge coating using powder metallurgical green compact electrodes. Mat. Manuf. Proces. 29(9), 1131–1138 (2014)

Singh, H., Banwait, S.S.: Experimental investigations of surface modification of AISI 1045 die steel by electro discharge machining process. Am. J. Mech. Eng. 4(4), 131–141 (2016)

Elaiyarasan, U., Satheeshkumar, V., Senthilkumar, C.: Surface modification of ZE41A magnesium alloy using electrical discharge coating with semi sintered electrode. Int. J. Mach. Mach. Mater. 21, 375–389 (2019)

Chakraborty, S., Kar, S., Dey, V., Ghosh, S.K.: Optimization and surface modification of al-6351 alloy using SiC–cu green compact electrode by electro discharge coating process. Surf. Rev. Lett. 24, 1750007–1750019 (2017)

Siddique, A.R., Mohanty, S., Das, A.K.: Micro-electrical discharge coating of Titani um alloy using WS2 and Brass P/M electrode. Mater. Manu. Proc. 34(15), 1761–1774 (2019)

Senthilkumar, C., Ganesan, G.: Electrical discharge surface coating of EN38 steel with WC/Ni composite electrode. J. Adv. Microsc. Res. 10, 202–207 (2015)

Tyagi, R., Pandey, P., Das, A.K., Mandal, A.: Deposition of hBN+ Cu Layer through electrical discharge process using green compact electrode. Mater. Manuf. Processes 28, 1–4 (2019)

Tyagi, R., Mahto, N.K., Das, A.K., Mandal, A.: Preparation of MoS2+Cu coating through the EDC process and its analysis. Surf. Engg. 36, 86–93 (2019)

Box, G.E.P., Wilson, K.B.: On the experimental attainment of optimum conditions. J. R. Stat. Soc. Ser. B (Methodol). 13(1), 1–45 (1992). (Wiley)

Chandran, R., Ramaiyan, S., Shanbhag, A.G.: Optimization of welding parameters for friction stir lap welding of AA6061-T6 alloy. Mod. Mech. Eng. 8(1), 31–41 (2018)

Tyagi, R., Das, A.K., Mandal, A.: Electrical discharge coating using WS2 and Cu powder mixture for solid lubrication and enhanced tribological performance. Trib Int. 120, 80–92 (2018)

Siddique, A.R., Mohanty, S., Das, A.K.: Microelectrical discharge coating of Titanium alloy using WS2 and Brass P/M electrode. Mat. Manuf. Process. 34, 1761–1774 (2019)

Mussada, E.K., Patowari, P.K.: Investigation of EDC parameters using W and Cu powder metallurgical compact electrodes. Int. J. Mach. Mach. Mater. 17(1), 65–72 (2015)

Jatti, V.S., Bagane, S.: Thermo-electric modelling, simulation and experimental validation of powder mixed electric discharge machining (PMEDM) of BeCu alloys. Alex. Eng. J. 57(2), 643–653 (2018)

Gill, A.S., Kumar, S.: Surface alloying of H11 die steel by tungsten using EDM process. Int. J. Adv. Manuf. Technol. 78(9–12), 1585–1593 (2015)

Senthilkumar, C.: Optimisation of EDC parameters using TOPSIS approach. Int. J. Mach. Mach. Mater. 21, 480–492 (2019)

Phan, N.H., Dong, P.V., Mthuramalingam, T., Thien, N.V., Dung, H.T., Hung, T.Q., Duc, N.V., Ly, N.T.: Experimental investigation of uncoated electrode and PVD AlCrNi coating on surface roughness in electrical discharge machining of Ti-6Al-4V. Int. J. Eng. 34(4), 928–934 (2021)

Ramdatti, J.L., Gohil, A.V., Dave, K.G.: Experimental investigation on electro-discharge surface modification phenomenon of P20+Ni die steel using green P/M composite electrode. J. Mech. Engg. Sci. 15(3), 8390–8404 (2021)

Phan, N.H., Muthuramalingam, T., Minh, N.D., Duc, N.V.: Enhancing surface morphology of machined SKD61 die steel in EDM process using DEAR approach based multi criteria decision making. Int. J. Interact. Des. Manuf. (2022).

Yap, C.Y., Liew, P.J., Yan, J.: Surface modification of tungsten carbide cobalt by electrical discharge coating with quarry dust suspension. Int. J. Adv. Manuf. Tech. 7–8, 2105–2116 (2020)

Phan, N.H., Dong, P.V., Mthuramalingam, T., Thien, N.V., Dung, H.T., Hung, T.Q., Duc, N.V., Ly, N.T.: Multi-object optimization of EDM by Taguchi-DEAR method using AlCrNi coated electrode. Int. J. Adv. Manuf. Tech. 116, 1429–1435 (2021)

Chena, C., Zengb, X., Wangb, Q., Liana, G., Huanga, X., Wangc, Y.: Statistical modelling and optimization of microhardness transition through depth of laser surface hardened AISI 1045 carbon steel. Opt. Las. Tech. 124, 105976–105987 (2020)

Acknowledgements

The author acknowledges Department of Manufacturing Engineering, Annamalai University, for the support and facilities provided to conduct the research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Srikanth, S., Senthilkumar, C. & Elaiyarasan, U. Experimental investigation and parametric optimization of electro-discharge coated aluminum alloy by desirability based technique. Int J Interact Des Manuf 17, 667–677 (2023). https://doi.org/10.1007/s12008-022-00983-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-00983-1