Abstract

This study investigates the influence of the surface free energy (SFE) on the adhesion behaviour between wheat dough and bakery-relevant food processing surfaces. In doing so, the contact time and production-related changes of the adhesive and the adherend were taken into account. The adhesion measurements were conducted by means of previously developed methods (modified Chen/Hoseney, contact time measuring cell), whereby the force required for separating the dough from the surface after processing-relevant contact times was determined applying a texture analyzer. The SFE was determined by contact angle measurements. The SFE values for the examined materials are ranged between 5.5 ± 0.81 and 42.7 ± 0.88 mN/m. A strong linear correlation between the SFE of the bakery surfaces and their adhesion to dough could be determined after a certain contact time (≥ 1 min) (r = + 0.96 for surfaces with Sa > 20 μm; r = + 0.94 for surfaces with Sa < 20 μm). Bakery surfaces with energy values σsolid surface, total > 30 mN/m including a polar content indicated a strong interaction with wheat dough, which was confirmed by high adhesion values. Production-related changes to the processing surfaces showed a great impact on the adhesion behaviour: e.g. the abrasion of proofing cloths caused a higher amount of protruding fibres, which operate as a separating layer, resulting in a decrease of dough adhesion even after long contact times. The results in this study emphasize the importance of the SFE in the development of processing surfaces for the baking industry.

Similar content being viewed by others

Introduction

Adhesiveness can be a desirable as well as undesirable product property of foods. The adhesiveness of dough during the processing usually leads to negative consequences such as production disruptions, loss of dough, and cleaning operations due to adhering dough residues on the processing surfaces. Bakeries are therefore interested in processing surfaces with low adhesive properties to dough. The type and strength of the adhesion is influenced by both systems, the material properties of the dough and the processing surface. Dough is a viscoelastic material, which is considered a pressure-sensitive adhesive (PSA): it is characterized by its ability to interact with the surface of another material after a brief contact with low pressure (Heddleson et al., 1993; Dobraszczyk, 1997; Ghorbel & Launay, 2014). According to the literature, the energy required to separate a PSA from a solid surface depends on predominant contributors: the rheology of the adhesive and the thermodynamic properties of the adhesive and the solid surface (adherend) (Michalski et al., 1997). However, most studies have so far focused on the adhesion behaviour based on dough material characteristics influenced by material components or process parameters (Dhaliwal & MacRitchie, 1990; Chen & Hoseney, 1995a; Couch & Binding, 2003; Jekle & Becker, 2011; Yildiz et al., 2012; Ghorbel et al., 2003). The most studies, dealing with the influence of the adhesive properties of processing surfaces, focuses on the influence of the physical properties such as surface roughness on the adhesion behaviour of dough (Ashokkumar & Adler-Nissen, 2011; Couch & Binding, 2003; Laukemper et al., 2019; Moeller & Nirschl, 2017; Huault et al., 2019). In general, the adhesion behaviour between two systems attempt to be explained by a large number of adhesion theories and models. The most developed is the thermodynamic adhesion theory (Packham, 2017). This theory considers adhesion to be a wetting process. When applying this theory, the surface free energy (SFE) is the most important parameter. The SFE is defined as the work required to enlarge the surface by one unit area (Packham, 2017). Theoretically, with knowledge of the respective surface energy of both contact partners, quantitative conclusions can be drawn about the resulting adhesion energy. Considering a large number of studies in adhesive technology, several studies from the food sector show a high influence of the SFE of food processing surfaces on the adhesion of the contacting food material (Avila-Sierra et al., 2019; Bhandari & Howes, 2005; Detry et al., 2010; Ghorbel & Launay, 2014; Keijbets et al., 2009; Wagoner & Foegeding, 2018). The studies generally state that the adhesion strength depends on the extent to which wetting is accomplished between the adherend and the adhesive. Thereby, the material properties such as the viscosity of the adhesive (dough) and the morphology of the respective processing surfaces play a decisive role when examining the relationship between the SFE and the adhesion behaviour between a solid surface and a flowable material (Noren et al., 2019). However, studies on the influence of the SFE of bakery-relevant surfaces on the adhesion behaviour to the viscoelastic dough system are very limited so far. Moreover, the few studies that exist on the influence of the SFE on the adhesion to dough did not consider the contact time between the two systems, which can have a great influence on the wetting behaviour. Furthermore, even small changes of the processing surfaces through practical application can strongly influence the SFE and thus the adhesive properties (Laukemper et al., 2018). During the baking process, the surface properties of, e.g., proofing cloths or conveyor belts are modified through the use of release flour, adhering dough residues, or abrasion of the materials through cleaning processes (including brushing) that can highly influence the surface structure (Moeller et al., 2017) and SFE of such materials. Such changes of the processing surfaces through the practical use must also be considered in the examinations of the effect of the SFE on the adhesion behaviour of dough.

The primary objective of this work was to investigate the effect of the surface free energy of bakery-relevant surfaces and wheat dough on the adhesion behaviour between both systems. The study is based on the hypothesis that the influence of the SFE depends on the wetting behaviour and thus on the contact time between the contact partners and on production-related surface changes. For this purpose, the surface energy of a wide range of bakery-relevant surfaces (stainless steel, conveyor belts, proofing trays, and baking foils), wheat dough, and wheat flour was determined with a laboratory contact angle measuring device. Additionally, the contact time–dependent adhesion was analyzed based on the development of Laukemper et al. (2019). Furthermore, the effect of production-related changes of the processing surfaces (provoked by raw material adherence and wear marks through cleaning) on the surface free energy and adhesion behaviour to dough was analyzed. The results aim to determine the relation between the surface free energy of food contact materials and the contact time–dependent adhesion behaviour of wheat dough.

Materials and Methods

Materials

The analyzed processing surfaces are applied in the baking industry and come into contact with dough throughout the manufacturing process (from kneading to baking).

Stainless Steel

The first contact between dough and a surface material occurs usually in a kneader with a stainless steel surface (e.g. kneading bowl, kneading tools). During the kneading process, a strong adhesion of the dough to the stainless steel surface can be observed. In this study, three different types of stainless steels were investigated, which are used for the production of kneading elements (see Table 1). All stainless steel surfaces are non-treated. The stainless steel plates were generously provided by Poligrat GmbH (Munich, Germany).

Conveyor Belts

For the transportation of dough pieces, a wide variety of conveyor belts are used. In this study, four commercially available conveyor belts of different composition were applied: tree smooth conveyor belts of thermoplastic polyurethane (TPU), thermoplastic polyolefin (TPO), polyvinylchloride (PVC), and a textile conveyor belt of polyethylene terephthalate (PET) fleece. All belts were generously provided by Habasit GmbH (Eppertshausen, Germany).

Proofing Cloths

Proofing cloths are often used for storage, transportation, and fermentation of dough. Five different commonly used proving cloth materials of cotton, polyester, and blended fabric generously provided by Nicolaus Weber GmbH, Fulda, Germany, were examined in this study. Table 2 shows the manufacturer specifications.

In plain weave cloth, the warp and weft threads cross at right angles, aligned so they form a simple criss-cross pattern. In rep weave cloths, a longitudinal or transverse, ribbed surface structure is created.

Baking Foils

Poly(organo)siloxane (silicone) and polytetrafluoroethylene (PTFE) materials are often used as baking foils and were also included in the investigations. The baking foils were received from Colory Sami Braun (Augsburg, Germany).

Methods

Surface Topography Characterization

To describe the surface topography and roughness of the individual materials, the KEYENCE digital microscope VHX-950F (KEYENCE DEUTSCHLAND GmbH, Neu-Isenburg, Germany) was used. The arithmetic mean (Sa) and mean square roughness (Sq) was calculated according to ISO 25178. The measurements were carried out at five different locations on material sample sizes of 5 × 5 cm. The results are shown in Table 3.

Dough Preparation

The wheat dough was prepared with German commercial wheat flour type 550 obtained from Rosenmühle (Landshut, Germany). According to the methods of the American Association of Cereal Chemistry international (AACCi) and of the International Association for Cereal Science and Technology (ICC), 13.92 ± 0.04-g moisture per 100-g flour (AACCi 44-01), 11.70 ± 0.03-g protein content per 100-g dry flour (AACCi 46-16, N × 5.7), and 0.63 ± 0.02-g ash per 100-g dry flour (ICC 104/1) were determined. In accordance to AACC method 54-21.02, a tourque measuring z-kneader (doughLAB; Perten Instruments, Germany) was used to determine the optimum water absorption and kneading time. In order to reach 500 Farino Units, the dough was prepared with 49.96-g wheat flour and 29.55 ml demineralized water and kneaded for 190 s at 63 rpm and a temperature of 30 °C.

Stickiness Measurement

For the measurement of the adhesion behaviour between the prepared wheat dough and the different bakery surfaces, two different methods were applied:

Modified SMS/Chen-Hoseney Rig

This method is based on the analysis of dough stickiness developed by Chen and Hoseney (1995b) using a texture analyzer (type TA.XT2, Stable Micro System, Godalming, England) with the SMS/Chen-Hoseney Dough Stickiness Rig which as modified according to Beck et al. (2009) by bonding a part of the sample material to the underside of the Plexiglas probe. Thus, the force required for separating the material from an extruded dough surface was received. Triplicate determinations of each surface material with 10 single measurements were performed. This method allows the determination of adhesion between dough and a contact surface after a short contact time (instantaneous release of the material after a holding time of 0.1 s).

CTM Cylinder Rig

This method was developed previously to analyze the contact time–dependent adhesion behaviour between dough and various materials (Laukemper et al., 2019). The CTM cylinder rig consists of a hollow cylinder with an opening (d = 12 mm) which is placed on a desk with the sample contact material and connected to a Texture Profile Analyzer (TPA) by a lever. The basic principle of the method is the detachment of the dough (located in the cylinder) from the material after a given contact time, wherein different adhesion values can be recorded by the TPA. In this study, contact times of 1 and 60 min between the dough sample and the bakery surface materials were studied and the maximum force Fmax (N) was evaluated. Triplicate determinations of each surface material with 5 single measurements were performed.

The stickiness measurements were carried out in an open-air condition at room temperature of 20 ± 1.5 °C and a relative humidity of approximately 50%. The surface temperature was also kept constant in all experiment at 20 °C.

Surface Free Energy Measurement

The surface free energy of the selected surface materials, of the dough surface and the flour, was determined by means of contact angle measurements of a polar and non-polar liquid using the sessile drop technique in an open-air condition at a room temperature of 20 ± 1.5 °C and a relative humidity of approximately 50% (Drop Shape Analyzer DAS 25E, Krüss, Germany). Therefore, the static contact angle between a distilled water drop (polar liquid) and a diiodomethane drop (apolar liquid) and the sample surface was measured visually by a CCD camera interfaced to a computer with the Advance Software version 1.31. Table 4 shows the test liquid data (surface tension including the polar and disperse fractions) according to Ström et al. (1987). Ten measurements were performed per sample and liquid. The stainless steel surfaces, the conveyor belts, and the baking foils were washed with pure water and wipes with Joseph paper before the measurement.

The surface free energy σs of the solid surfaces was calculated according to Owens-Wendt-Rabel-Kaelble by the contact angle data, including its polar \( {\sigma}_{\mathrm{s}}^p \) and disperse \( {\sigma}_{\mathrm{s}}^d \) fractions (Żenkiewicz, 2007), whereby σ = σd + σp applies.

Young formulated a relationship about interfacial tension at a three-phase point liquid/solid/air:

For cases where both dispersive and polar interactions operate across the interface between the both contact partners, the interfacial tension σsl is given by Owens and Wendt (1969):

Adjustments of the Method for the Surface Free Energy Determination of Textiles, Powders, and Dough

The determination of the contact angles of textile materials, having protruding fibres, was determined according to Laukemper et al. (2018), applying a clamping device. In this method, the material is stretched over a small bridge avoiding disturbances of drop analysis by protruding fibre hairs of the textiles in front of and behind the drop. For the determination of the surface energy of the dough surface, the dough was directly rolled out after kneading (0.5 cm width) and placed on the clamping device. The contact angles of the polar and disperse liquids were measured directly within 5 min. The contact angle measurements of the wheat flour was conducted according to Roman-Gutierrez et al. (2002): 30 g of flour were filled into a metal ring with a diameter of 6 cm. Compacts were made by pressing the wheat flour at a pressure of 1 kPA for 1 min at room temperature. The samples were examined immediately after preparation.

Surface Modifications

The surface properties especially of proofing cloth materials can change rapidly during production. The use of release flour and the abrasion of the materials due to cleaning operations like brushing of the materials play an enormous role and can have a great effect on the material characteristics. In this work, the influence of such surface changes on the surface energy and adhesion properties to dough of three different proofing cloths materials were investigated.

To adjust the ageing of the materials through the practical use, the proofing cloth materials were brushed with a brushing apparatus at the Karlsruher Institute of Technology, Mechanical Process Engineering and Mechanism in Germany according to Moeller et al. (2017). The number of brushing reruns was chosen to match a practical operation. To study the influence of release flour, 0.1-g wheat flour per cm2 (type 550, Rosenmühle GmbH, Landshut, Germany) was evenly distributed with a sieve and pressed with a 300-g weight for 5 s. Brushing strongly influences the number and length of protruding fibres of the proofing cloths. As can be seen in Fig. 1, the effect is strongly dependent on the material type: From a visual point of view, the largest increase in the protruding fibres occurred in the polyester proofing cloth. Moeller et al. (2017), who investigated the influence of brushing on the surface properties (roughness) according to ISO 25178 (DIN EN ISO, 2012) of the same materials, identified the highest increase of the hairiness and the Sxp value (peak extreme height indicates the heights of the surfaces upper half) for polyester proofing cloths as well. This part of this study was conducted in close collaboration with the Karlsruher Institute of Technology, Mechanical Process Engineering and Mechanism in Germany.

Statistical Analysis

The statistical analysis was performed with the aid of Prism 6 (version 6.01, GraphPad Software, Inc., La Jolla, USA). Correlation analyses were used to investigate the relationship between variables. Consequently, correlations between the results of the adhesive force and the surface free energy values were analyzed, whereby the correlation coefficient (r) represents strength and direction of a linear relationship. To detect significant differences between the samples, a one-way ANOVA followed by Tukey test (p < 0.05) was applied.

Results and Discussion

Surface Topography

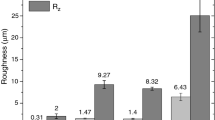

During the production of baking goods, dough usually comes in contact with several different food contact materials such as stainless steel during the kneading process, with conveyor belts of different coatings during the transportation, with proofing trays which are often made of textile proofing cloths, and with baking foils. These surfaces differ not only in their composition, but also in their surface topography. As already reported in the “Introduction” section, in addition to the surface energy, the surface topography has a decisive influence on the adhesion properties of food contact materials. The surface roughness determines the area available for interactions with another material. The arithmetic mean (Sa) and mean square roughness (Sq) was calculated according to ISO 25178 for all investigated materials in the frame of this study. These values were chosen for its high validity and widespread use. The results are shown in Table 3. Values of the surface roughness of similar food contact materials of the scientific study of Moeller and Nirschl (2017) are in a related range. The roughness values of the stainless steel samples and the conveyor belts made of TPU, PVC, and TPO are in a similar range between Sa = 1.21–2.85 μm, those of the baking foils at Sa = 10.21 μm for PTFE baking foils, and Sa = 18.89 μm for silicone baking foils. The determined roughness values of the textile proofing cloths are significantly higher with Sa values between 31.83 and 53.17 μm. The high values of the textiles result from the protruding fibres, which occur naturally as in the case of cotton or through melt-spun as in the case of polyester. With regard to the roughness values and type of material, the materials in this study are divided into two parts: smooth “non-textile” surfaces with Sa < 20 μm and highly structured textile surfaces with Sa > 20 μm.

Surface Free Energy Values Including the Polar and Disperse Fractions of All Contact Partners

The investigation of the surface free energy was conducted for a high range of bakery-relevant materials as well as for a wheat dough system (standard wheat dough consisting of flour and water 59.1 g/100-g flour) and a pressed flour surface by optical contact angle measurements using the Drop Shape Analysis System DSA25 from Krüss GmbH according to Owens, Wendt, Rabel, and Kaelble (Owens & Wendt, 1969).

Figure 2 shows the ascertained total surface free energy values including the polar and disperse fractions using the Owens and Wendt geometric mean approach of the evaluated bakery surfaces (a–d), for pressed flour and wheat dough (e). The analyzed bakery surfaces differ greatly in the total surface free energy; the values for the examined materials are ranged between 5.5 ± 0.81 and 42.7 ± 0.88 mN/m. Values of the surface free energy of similar food contact materials of other scientific studies are in a related range (Bhandari & Howes, 2005; Lewin et al., 2005; Güleç et al., 2006; Keijbets et al., 2009; Hejda et al., 2010; Williams & O’Bryon, 2013; Mousavi et al., 2013; Ghorbel & Launay, 2014; Magens et al., 2017; Avila-Sierra et al., 2019). Common materials for process equipment in the production of food and transportation are stainless steel or plastic-coated conveyor belts, which have high surface energy values. For the examined bakery-relevant surfaces, the surface energy values for all stainless steel materials, for PVC and TPU conveyor belts, and for the polyester proofing cloth are > 30 mN/m and thus rather high. According to the theory, these materials are easily wetted (high affinity towards interaction). Good wettability means that the adhesive and the adherend have a strong mutual affinity and are likely to adhere well (Michalski et al., 1997). Good wettability of the surface is the most important prerequisite for the formation of adhesive forces. The surface energy values for the PTFE and silicone baking foils, primarily cotton proofing cloths and PET-fleece conveyor belts, are quite low; such low-energy surfaces are poorly or only incompletely wetted and thus ensure merely the formation of low adhesive forces.

Values of surface free energy and their polar and disperse fractions (determined by the Owens and Wendt approach) of a stainless steel (SS) surfaces; b conveyor belts (CB) of thermoplastic polyurethane (TPU), thermoplastic polyolefin (TPO), polyvinylchloride (PVC), and a textile conveyor belt of polyethylene terephthalate (PET) fleece; c proofing cloths (PC) of different material composition (CO: 100% cotton; P/CO: 70% polyester/30% cotton; P: 100% polyester); d baking foils (BF) of poly(organo)siloxane (silicone) and polytetrafluoroethylene (PTFE); and e a pressed flour layer and of wheat dough. Means are shown with standard deviation (n = 10)

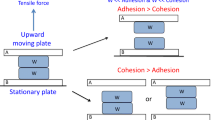

Furthermore, the ratio of the surface energy of the surfaces and adhesives plays a decisive role for the adhesion behaviour between the contacting materials. Adhesiveness is thermodynamically favourable when the surface energy of the adherend is greater than that of the adhesive. Low-energy materials absorb strongly to high-energy surfaces to lower the surface energy of the system (Michalski et al., 1997; Owens & Wendt, 1969; Saunders et al., 1992).

A total surface energy value of 29.25 mN/m was measured for a freshly cut dough surface. According to the literature, the adhesion of the stainless steel surfaces; the coated conveyor belts of TPU, PVC, and TPO; and the proofing cloths of polyester and blended fabric surfaces to the adhesive dough should be rather high. A low adhesion of the dough would be formed to PTFE and silicone baking foils, the PET-fleece conveyor belt, and the cotton proofing cloths.

Moreover, according to Owens, Wendt, Rabel, and Kaelble, the polar part and a disperse part of the total surface free energy must be comprised (Kaelble, 2008). When the surface energy of the two phases have similar values, a close matching of the polarities is necessary for complete wetting. The more the dispersive and polar correspond to each other, the more interactions there are between the phases that a stronger adhesion can be expected (Wu, 1973). Dispersive contributions indicate weak van der Waals type interactions (non-polar molecule interactions), where all materials have at least some portion of dispersive surface energy; polar contributions represent hydrogen bonding and dipole-dipole interactions, such interactions are comparatively stronger (Wu, 1973). According to this theory, non-polar surfaces with low surface energy exhibit low adhesiveness. Surfaces with these properties are used in the food industry as non-stick coatings. For the results of this work, this interpretation would mean a high interaction between dough (high polar content of\( {\sigma}_{\mathrm{dough}}^p \) = 25.01 ±1.86) and the stainless steel surfaces as well as with the proofing cloth of polyester and blended fabric (similar surface energy, high polar component).

However, it must be noted, if the surface energy of the two phases are widely different, matching of the polarity becomes less important. In other words, when the surface energy of the adhesive is much smaller than that of the adherend, complete wetting may still occur, although the polarities are relatively widely apart. That would mean a high adhesion between the dough and the PVC and TPU conveyor belts due to their significant higher surface energy compared with the surface energy of the adhesive. A low interaction between the dough and PTFE and silicone baking foils, the PET-fleece conveyor belt, and the cotton proofing cloths can be assumed through the low surface energy and low polar component of the adherends.

What has not been taken into account in the previous studies is that the dough is often not in direct contact with the surface. Release flour is often used during the production of baking goods, which is located as a separating layer between the adhesive and the adherend. For this reason, the surface energy of this interface was also determined according to Roman-Gutierrez et al. (2002): The surface energy of the flour has a value of 21.67 mN/m, which is lower than that of the wheat dough, and contains a significantly lower polar content (\( {\sigma}_{\mathrm{wheat}\ \mathrm{flour}}^p \) = 2.62 ± 0.52 mN/m).

Surface Adhesion of Wheat Dough

The adhesion between wheat dough consisting of flour and water and a high variation of bakery-relevant materials was analyzed with the modified SMS/Chen-Hoseney Stickiness Rig after a short contact time (0.1 s) and with the CTM measuring method after varying contact times (1 and 60 min). Table 5 shows the results of the surface adhesion between wheat dough and various bakery-relevant surfaces, which are used during the production of baking goods. Comparing the results of the surface adhesion of dough after a contact time of 0.1 s (analyzed with the mod. Chen/Hoseney Rig), a high difference of the values can be recognized between the non-textile smooth surfaces with a lower roughness < 20 μm and “textile” surfaces (proofing cloths and conveyor belt of PET-Fleece) with higher roughness values > 20 μm. The values for the smooth surfaces are in a range from 0.375 to 0.534 N and all higher than those for the textile materials, which are in a range from 0.158 to 0.314 N. Similar results for comparable materials have already been found in a previous work (Laukemper et al., 2019). The strong structuring of the textile materials through protruding fibres results in a punctual contact between the dough and the fibres resulting in a lower adhesion between the two contact partners after a short contacting. Through the straightened up fibres, the dough is kept from coming into close contact with the rest of the textile’s surface; the protruding fibres act like a separating layer. A higher difference between the various types of material (a–d) could be determined after a longer contact time. Since a different measurement method (CTM method) had to be used for this measurement, the results cannot be compared directly with the results of the Chen/Hoseney analyses. Regarding the results after a contact time of 1 min, significant highest surface adhesion values revealed for the stainless steel and smooth conveyor belt surfaces in a range from 0.112 to 0.151 N, followed by a lower surface adhesion behaviour of the baking foils (0.058–0.078 N), and a noticeably low surface adhesion of the proofing cloths and the PET-Fleece-CB (0.011–0.039 N). The results relate with the results of the roughness measurements (see Table 3): The surface adhesion to wheat dough seems to decrease with an increase of the surface roughness. The influence of surface roughness on adhesion has already been examined in several studies in other areas and the same effect could be observed: Increasing the roughness of the surface material results in a decrease of the surface adhesion behaviour through poorer molecular contact between the adherend and the adhesive (Hui et al., 2000; Gay, 2002). In this study, however, this assertion can only be made for high differences in roughness; no relation between the roughness and surface adhesion can be observed within the individual material groups. In addition, in case of non-textile materials, the contact area between the higher structured adhered surface and the viscoelastic adhesive should have been increased with a longer contact time (60 min) due to the penetration of the viscoelastic dough, and thus the adhesion should have been increased. This could not be observed in the measurements of this study. An increase of the surface adhesion after a higher contact time was observed for all materials. Striking values can be seen in the results of the proofing cloth (B). After a short contact time between the dough and the materials, measured with the modified Chen/Hoseney method, there is no clear difference between the adhesion results. After a contact time of 1 and 60 min, a significant difference of the adhesion behaviour was identified between the polyester/blended fabric and cotton proofing cloth, despite similar roughness values. For polyester and blended fabric proofing cloths, significantly higher values (Fmax,t = 1 min = 0.027 N − 0.039 N and Fmax,t = 60 min= 0.073 N − 0.114 N) were observed than those for the cotton proofing cloths (Fmax,t = 1 min = 0.009 N − 0.013 N and Fmax,t = 60 min= 0.044 N − 0.058 N) using the CTM method for the measurements. The extent to which the surface energy of the adhered and adhesive affects the contact time–dependent adhesion is discussed in the following “Results and Discussion” section.

Correlation Between Surface Free Energy and Surface Adhesion of Wheat Dough

Plotting the total surface free energy against the surface adhesion Fmax,0.1 s, which was measured after a very short contact time applying the modified Chen/Hoseney method, a weak positive correlation can be seen for the smooth surfaces with Sa values < 20 μm (r = + 0.619) and for the textile with Sa values < 20 μm (r = + 0.563) (see Fig. 3, right). However, a strong positive correlation occurs when plotting the surface free energy values against the surface adhesion values measured with the CTM method after a contact time of 1 min for the smooth surfaces (r = + 0.940) and for the textile surfaces (r = + 0.962) (see Fig. 4). Even after a contact time of 60 min, a positive correlation between the surface free energy and the surface adhesion could be calculated (r = + 0.923 for smooth surfaces and r = + 0.951 for textile surfaces) (see Fig. 5).

Surface adhesion force (Fmax: peak separation force) of wheat dough measured with modified Chen/Hoseney method as a function of the total surface energy. Left: results of the all measured contact surfaces as single points (black circle: P-PT-1/2; black square: P/CO-PT; black triangle: CO/PT-1/2; white circle: PVC/TPU/TPO-CB; black diamond: SS 1/2/3; black and white square: P-fleece-CB; black and white circle: PTFE-BF; white circle with an x: silicone-BF). Right: results considered separately for highly structured surfaces (white triangle) (Sa values > 20 μm) and low structured surfaces (black circle) (Sa values < 20). Solid lines present linear correlation for a highly structured (r = + 0.563) and b low structured surfaces (r = + 0.619). Means of stickiness measurements (n = 10) and of surface free energy measurements (n = 10) are shown with standard deviation

Surface adhesion force (Fmax: peak separation force) of wheat dough measured with CTM method after 1 min contact time as a function of the total surface energy. Left: representation of the results of the all measured contact surfaces as single points (black circle: P-PT-1/2; black square: P/CO-PT; black triangle: CO/PT-1/2; white circle: PVC/TPU/TPO-CB; black diamond: SS 1/2/3; black and white square: P-fleece-CB; black and white circle: PTFE-BF; white circle with an x: silicone-BF). Right: results considered separately for highly structured surfaces (white triangle) (Sa values > 20 μm) and low structured surfaces (black circle) (Sa values < 20). Solid lines present linear correlation for highly structured (r = + 0.962, p < 0.01) and low structured surfaces (r = + 0.940, p < 0.01). Means of stickiness measurements (n = 10) and of surface free energy measurements (n = 10) are shown with standard deviation

Surface adhesion force (Fmax: peak separation force) of wheat dough measured with CTM method after 60-min contact time as a function of the total surface energy. Left: representation of the results of the all measured contact surfaces as single points (black circle: P-PT-1/2; black square: P/CO-PT; black triangle: CO/PT-1/2; white circle: PVC/TPU/TPO-CB; black diamond: SS 1/2/3; black and white square: P-fleece-CB; black and white circle: PTFE-BF; white circle with an x: silicone-BF). Right: representation of the results considered separately for highly structured surfaces (white triangle) (Sa values > 20 μm) and low structured surfaces (black circle) (Sa values < 20). Solid lines present linear correlation for highly structured (r = + 0.923, p < 0.01) and low structured surfaces (r = + 0.951, p < 0.001). Means of stickiness measurements (n = 10) and of surface free energy measurements (n = 10) are shown with standard deviation

Pressure-sensitive adhesiveness is a product of adhesive rheology and surface energy (Michalski et al., 1997). That means that the strength of the adhesion force depends on the extent to which wetting is accomplished between the adherend and the adhesive. According to the thermodynamic adhesion theory, two phases can only adhere to each other if they are brought close together that intermolecular forces become operative (Shanahan, 1991). Therefore, the wetting process plays a crucial role in describing the thermodynamic adhesion. The complete wetting process of the surface with the viscoelastic dough system only takes place after a certain contact time and proximity that could not take place with the investigated materials after an instantaneously detachment of the dough. Despite the very different surface energy values of the smooth and the textile surfaces, all adhesion values are in the same range. After this short contacting of the adherend and the adhesive, roughness seems to play a more dominant role in the adhesion behaviour. Especially for the textile surfaces, the protruding fibres keep the dough from coming into closer contact with the rest of the textile that prevents the wetting of the surface by the dough, and thereby, low intermolecular interactions occur.

After a contact time of 1 min, the dough is distributed over the entire surface; a complete wetting occurs, so that the influence of the surface energy of both contact partners has a greater impact and the influence of the surface roughness for the respective material types decreases. Wetting of the surface by the wheat dough is a time-dependent process, as the wheat dough changes its rheological properties over time. Due to structural relaxation after kneading (Kim et al., 2008) and network degradation caused by enzyme activity (Wu & Hoseney, 1989), the dough gets more fluid that leads to a higher penetration of the dough into the materials and thus higher interactions between the two contact partners through a higher contact area. In this study, this observation affects an increase in the surface adhesion force for all materials after a contact time of 60 min (see Fig. 5). The noticeable high increase of the surface adhesion force between the dough and the polyester proofing cloths only after a higher contact time could result through the special structuring: After a short contact time, the protruding fibres still act as a barrier; the contact points of the contact partners are quite low resulting in low interaction possibilities. The increasing contact area through penetration of the dough into the surface in combination of resulting mechanical interlocking and drying processes of the dough could be a possible explanation.

The results after a longer contact time (Figs. 4 and 5) can be described in accordance with the thermodynamic adhesion theory: The adhesiveness is stronger for surfaces with greater surface energy values than of the wheat dough. Furthermore, the higher polar component of this material results in a higher affinity of molecular interactions and thus stronger adhesion forces with the highly polar dough surface. The adhesiveness of dough to lower energy surfaces is significantly lower.

Food contact materials with a surface energy < 25 mN/m (and a low polar content < 1 mN/m) are recommended for bakeries when a low adhesion to dough is desirable. Such surfaces are poorly wetted by the wheat dough, which has a higher surface energy with a very high polar content, so that hardly any intermolecular interactions can take place. The results of this study confirm this theory. A comparable value appeared in the study of Keijbets et al. (2009), who investigated the influence of the surface free energy of solid mould materials on the adhesion behaviour of chocolate. In this study, surfaces with a surface free energy < 30 mN/m are recommended as suitable mould materials for low chocolate adhesion.

Effect of Production-Related Changes of Proofing Cloths on SFE and Adhesion to Dough

The influence of production-related changes like the deposit of release flour on the processing surfaces of the wear of the materials through brushing on the change of the surface free energy and the adhesive behaviour of these materials to dough was investigated on 3 proofing cloths of different material composition. Figure 1 visualizes the effect of brushing on the material structuring: an increase of the number and length of protruding fibres for all materials. Table 6 shows the results of the surface free energy measurements of the untreated (plain), the brushed and the floured proofing cloths: A separating layer such as release flour and the change in the surface structure through brushing has a very high influence on the surface free energy values of all materials. A thin layer of flour has a less effect than the strong structural change caused by brushing. The lower surface energy of the flour with σflour = 21.67 mN/m (see Fig. 2) could cause the decrease of the surface free energy in the polyester and blended cloths, whereat it causes an increase of the cotton cloths. The strongest influence of brushing can be seen in the polyester cloths, a strong decrease in surface energy from 31.78 to 1.17 mN/m was determined. Moeller et al. (2017), who investigated the effect of the structural changes of the same materials, determined the strongest increase of the hairiness (increasing Sxp values according to DIN ISO 25178) for all proofing cloth, the strongest increase for polyester proofing cloths. The significantly increased microstructuring tend to reduce the contact area between the test liquids and the solid surface by separating the two phases and thereby increasing the preeminence of the surface tension (Bhushan & Her, 2010; Bico et al., 2002; Kota et al., 2014). This behaviour corresponds to the “lotus effect”. In the current experiment, the contact angles of both sample liquids were > 140° that leads to very low surface energy values. Such materials are designated as superhydrophobic and oleophobic (Brewer & Willis, 2008).

The effect of the changes of the material properties through industrial use on the surface adhesion behaviour to dough was examined in a further step (see Table 7). Release flour and brushing of the proofing cloths greatly reduced the adhesion to wheat dough after an instantaneously detachment of the dough from all proofing cloths. The greatest reduction in the adhesion to dough through brushing was found for the polyester cloths in which brushing increased the amount of protruding fibres (hairiness) the most. As well as the release flour, the protruding fibres also act as a separating layer and keep the dough from coming close to the textile’s surface. The dough only adheres to these fibres and can easily be detached. However, this strong reduction in the adhesion due to release flour and brushing could just be determined after an immediate detachment of the material from the dough and thus after a short contact time. This strong effect could not be determined after a contact time of 60 min. A significant reduction of the adhesion after this long contact time could only be determined for the polyester cloths. For cotton proofing cloths, the use of release flour actually increased the adhesion to dough slightly. As the release flour particles are moistened over time and bond to the wheat dough, the release flour loses its function as a separating layer. As discussed before, wheat dough changes its rheological properties over time and get more fluid. As a result, the dough distributes over the entire surface and might penetrate into the indentations of the materials.

Despite the low adhesive properties of the tested cotton cloths, polyester cloths are advantageous due to their better drying properties and composition in terms of the microbial contamination (Laukemper et al., 2018), so that an optimization of the adhesive properties of polyester cloths through specific structuring would have great benefits.

Conclusion

Surface free energy is becoming increasingly important when interpreting the adhesion phenomena in a wide variety of areas. This paper deals with the effect of the surface free energy (including polar and disperse components) of bakery-relevant surfaces (adherend) and wheat dough (adhesive) on the adhesion behaviour between both systems taking production-related contact times and changes of the surfaces (structure, release agent) and the wheat dough (rheology) into account.

Applying a previously developed method for the examination of the contact time–dependent adhesion behaviour of wheat dough and food contact surfaces, important observations were made. A relation between the surface energy and the adhesion behaviour of dough and processing surfaces could be determined for the first time after a certain contact time in the adhesion measurements of the two contact partners. However, after a specific contact time, a very high linear relation between solid and smooth as well as for textile and fibrous surfaces was identified. These results arise from the wetting behaviour of the processing surfaces by the adhesive wheat dough, which depends on the viscoelastic behaviour of the dough, the roughness of the processing surfaces and thus the contact time between the two systems. Furthermore, the results showed a dependency of the surface energy relationship of the adhesive and adherend: Surfaces with high surface energy values (σsolid surface, total > 30 mN/m) resulted in high adhesion values to dough, indicating a strong interaction of the two contact partners, surfaces with surface energy values below σsolid surface, total < 25 mN/m and a low polar component (σsolid surface,polar < 5 mN/m) show significantly reduced adhesion to dough even after a long contact time (60 min). In conclusion, dough adhesiveness is a dynamic property influenced by (a) the receipt and thus the rheological properties and (b) the interfacial energy between dough and its contacting surface.

Production-related changes of proofing cloth materials resulted in significantly different surface energy values: An increased surface structuring through the increase in protruding fibres operate as a separating layer, resulting in a significant decrease of the adhesion behaviour to wheat dough after a short contact time. For the high adhesive polyester proofing cloths, the increase of protruding fibres represents a promising alternative to the use of release flour to reduce the adhesion of dough even after long contact times.

The results of this study present the relevance of the surface free energy depending on the contact time and production-related surface modifications when selecting processing surfaces for the baking industry.

References

Ashokkumar, S., & Adler-Nissen, J. (2011). Evaluating non-stick properties of different surface materials for contact frying. Journal of Food Engineering, 105(3), 537–544.

Avila-Sierra, A., Zhang, Z. J., & Fryer, P. J. (2019). Effect of surface characteristics on cleaning performance for CIP system in food processing. Energy Procedia, 161, 115–122.

Bhandari, B., & Howes, T. (2005). Relating the stickiness property of foods undergoing drying and dried products to their surface energetics. Drying Technology, 23(4), 781–797.

Bhushan, B., & Her, E. (2010). Fabrication of superhydrophobic surfaces with high and low adhesion inspired from rose petal. Langmuir: the ACS Journal of Surfaces and Colloids., 26(11), 8207–8217.

Beck, M., Jekle, M., Hofmann, S. T., & Becker, T. (2009). Novel materials and surface investigations for optimizing dough carrier interactions. European Food Research and Technology, 229(2), 183–189.

Bico, J., Thiele, U., & Quéré, D. (2002). Wetting of textured surfaces. Colloids and Surfaces. A, Physicochemical and Engineering Aspects, 206(1), 41–46.

Brewer, S. A., & Willis, C. R. (2008). Structure and oil repellency: Textiles with liquid repellency to hexane. Applied Surface Science, 254(20), 6450–6454.

Chen, W. Z., & Hoseney, R. C. (1995a). Wheat flour compound that produces sticky dough: Isolation and identification. Journal of Food Science, 60(3), 434–437.

Chen, W. Z., & Hoseney, R. C. (1995b). Development of an objective method for dough stickiness. LWT - Food Science and Technology, 28(5), 467–473.

Couch, M. A., & Binding, D. M. (2003). An experimental study of the peeling of dough from solid surfaces. Journal of Food Engineering, 58(4), 299–309.

Dhaliwal, A. S., & MacRitchie, F. (1990). Contributions of protein fractions to dough handling properties of wheat-rye translocation cultivars. Journal of Cereal Science, 12(2), 113–122.

Detry, J. G., Sindic, M., & Deroanne, C. (2010). Hygiene and cleanability: A focus on surfaces. Critical Reviews in Food Science and Nutrition, 50(7), 583–604.

Dobraszczyk, B. J. (1997). The Rheological Basis of Dough Stickiness. Journal of Texture Studies, 28(2), 139–162.

Gay, C. (2002). Stickiness--some fundamentals of adhesion. Integrative and Comparative Biology, 42(6), 1123–1126.

Ghorbel, D., & Launay, B. (2014). An investigation into the nature of wheat flour dough adhesive behaviour. Foodservice Research International, 64, 305–313.

Ghorbel, D., Launay, B., & Heyd, B. (2003). Improved method for measuring wheat flour dough pressure-sensitive adhesiveness. Cereal Chemistry Journal, 80(6), 732–739.

Güleç, H. A., Sarıogˇlu, K., & Mutlu, M. (2006). Modification of food contacting surfaces by plasma polymerisation technique. Part I: Determination of hydrophilicity, hydrophobicity and surface free energy by contact angle method. Journal of Food Engineering, 75(2), 187–195.

Heddleson, S. S. H., Hamann, D. D., & Lineback, D. R. (1993). The Dahlquist criterion: Applicability of a rheological criterion to the loss of pressure-sensitive tack in flour-water dough. Cereal Chemistry, 70(6), 744–748.

Hejda F, Solar P, Kousal J. Surface free energy determination by contact angle measurements-A comparison of various approaches. Chemistry, 2010;25–30.

Huault, L., Vésinet, M., Brogly, M., Giampaoli, P., Bistac, S., & Bosc, V. (2019). Adhesion of bread dough to solid surfaces under controlled heating: Balance between the rheological and interfacial properties of dough. Journal of Food Science, 84(3), 499–506.

Hui, C. Y., Lin, Y. Y., & Baney, J. M. (2000). The mechanics of tack: Viscoelastic contact on a rough surface. Journal of Polymer Science Part B: Polymer Physics., 38(11), 1485–1495.

Jekle, M., & Becker, T. (2011). Dough microstructure: Novel analysis by quantification using confocal laser scanning microscopy. Foodservice Research International, 44(4), 984–991.

Kaelble, D. H. (2008). Dispersion-polar surface tension properties of organic solids. Journal of Adhesion - J ADHES., 2, 66–81.

Keijbets, E. L., Chen, J., Dickinson, E., & Vieira, J. (2009). Surface energy investigation of chocolate adhesion to solid mould materials. Journal of Food Engineering, 92(2), 217–225.

Kim, Y.-R., Cornillon, P., Campanella, O. H., Stroshine, R. L., Lee, S., & Shim, J.-Y. (2008). Small and large deformation rheology for hard wheat flour dough as influenced by mixing and resting. Journal of Food Science, 73(1), E1–E8.

Kota, A., Kwon, G., & Tuteja, A. (2014). The design and applications of superomniphobic surfaces. NPG Asia Materials, 6(7), e109.

Laukemper, R., Jekle, M., & Becker, T. (2019). Time-dependent adhesion behavior between dough and contact surfaces in bakeries. Journal of Food Engineering, 255, 24–31.

Laukemper, R., Maria Giraldo, A., Hofmann, S., Jekle, M., Jekle, M., & Becker, T. (2018). Microbial contamination and surface properties of proofing carrier cloths after a long-term use. Cereal Technology., 1, 4–12.

Lewin, M., Mey-Marom, A., & Frank, R. (2005). Surface free energies of polymeric materials, additives and minerals. Polymers for Advanced Technologies, 16(6), 429–441.

Magens, O. M., Liu, Y., Hofmans, J. F. A., Nelissen, J. A., & Ian, W. D. (2017). Adhesion and cleaning of foods with complex structure: Effect of oil content and fluoropolymer coating characteristics on the detachment of cake from baking surfaces. Journal of Food Engineering, 197, 48–59.

Michalski, M. C., Desobry, S., & Hardy, J. (1997). Food materials adhesion: A review. Critical Reviews in Food Science and Nutrition, 37(7), 591–619.

Moeller, R.-S., Duchardt, A., & Nirschl, H. (2017). Ageing proving cloths–Effects on surfaces and usability. Journal of Food Engineering, 214, 218–225.

Moeller, R.-S., & Nirschl, H. (2017). Adhesion and cleanability of surfaces in the baker’s trade. Journal of Food Engineering, 194, 99–108.

Mousavi, Z. E., Fanning, S., & Butler, F. (2013). Effect of surface properties of different food contact materials on the efficiency of quaternary ammonium compounds residue recovery and persistence. International Journal of Food Science and Technology, 48(9), 1791–1797.

Noren, N. E., Scanlon, M. G., & Arntfield, S. D. (2019). Differentiating between tackiness and stickiness and their induction in foods. Trends in Food Science and Technology, 88, 290–301.

Owens, D. K., & Wendt, R. C. (1969). Estimation of the surface free energy of polymers. Journal of Applied Polymer Science, 13(8), 1741–1747.

Packham, D. E. (2017). Theories of fundamental adhesion. Handbook of Adhesion Technology, 1–31.

Roman-Gutierrez, A. D., Guilbert, S., & Cuq, B. (2002). Distribution of water between wheat flour components: A dynamic water vapour adsorption study. Journal of Cereal Science, 36(3), 347–355.

Saunders, S. R., Hamann, D. D., & Lineback, D. R. (1992). A systems approach to food material adhesion. LWT – Food Science and Technology, 25, 309–315.

Shanahan, M. E. R. (1991). Adhesion and wetting: Similarities and differences. Rubber World; (United States): N. p., Web.

Ström, G., Fredriksson, M., & Stenius, P. (1987). Contact angles, work of adhesion, and interfacial tensions at a dissolving hydrocarbon surface. Journal of Colloid and Interface Science, 119(2), 352–361.

Wagoner, T. B., & Foegeding, E. A. (2018). Surface energy and viscoelasticity influence caramel adhesiveness. Journal of Texture Studies, 49(2), 219–227.

Williams, D. L., & O’Bryon, T. M. (2013). Chapter 5-Cleanliness verification on large surfaces: instilling confidence in contact angle techniques. In R. Kohli & K. L. Mittal (Eds.), Developments in surface contamination and cleaning (pp. 163–181). Oxford: William Andrew Publishing.

Wu, S. (1973). Polar and nonpolar interactions in adhesion. The Journal of Adhesion, 5(1), 39–55.

Wu, J. Y., & Hoseney, R. C. (1989). Rheological changes in cracker sponges during an 18-hour fermentation. Cereal Chemistry Journal., 66(3), 182–185.

Yildiz, O., Meral, R., & Dogan, I. S. (2012). Determination of stickiness values of different flour combinations. International Journal of Food Engineering, 8(3).

Żenkiewicz, M. (2007). Methods for the calculation of surface free energy of solids. Journal of Achievements in Materials and Manufacturing Engineering, 24(1), 137–145.

Acknowledgements

The authors gratefully acknowledge the pleasant cooperation, support, and fruitful discussions with the project partners Dr.-Ing. Richard-Sebastian Moeller and Prof. Dr. Ing. Habil. Hermann Nirschl of the Karlsruhe Institute of Technology, Institute of Mechanical Process Engineering and Mechanics.

Funding

Open Access funding enabled and organized by Projekt DEAL. This IGF Project of the FEI was supported via AiF (17831 N) within the programme for promoting the Industrial Collective Research (IGF) of the German Ministry of Economic Affairs and Energy (BMWi), based on a resolution of the German Parliament.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Laukemper, R., Becker, T. & Jekle, M. Surface Energy of Food Contact Materials and Its Relation to Wheat Dough Adhesion. Food Bioprocess Technol 14, 1142–1154 (2021). https://doi.org/10.1007/s11947-021-02625-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-021-02625-y