Abstract

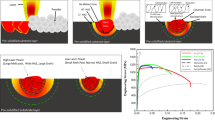

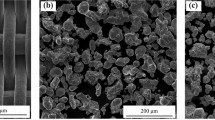

The 15% WC particle reinforced maraging steel 300 composites were fabricated by laser powder bed fusion. The effects of solid solution temperature, solid solution time, and aging temperature on the mechanical properties and morphology of the composite were then investigated using the response surface approach. The results show that the three heat treatment parameters have an interaction effect on yield strength and Rockwell hardness. The optimum heat treatment parameters obtained using the response surface method are solid solution at 846°C for 51 min and aging at 388°C for 300 min. After heat treatment, the melt pool of the sample formed by laser powder bed fusion disappears. The morphology is inhomogeneous cellular crystals and dendritic crystals before heat treatment. After the optimal and the worst heat treatments, the microstructure transforms into lath and acicular martensite, and its uniformity is remarkably improved. The heat treatment prompts mutual dissolution and diffusion between the WC reinforcing particles and the maraging steel 300 composites. The precipitated phases are dispersed along the grain boundary, and the thickness of the diffusion layer increases. After optical heat treatment, the composites' yield strength and Rockwell hardness increase by 129.4% and 52.3%, respectively.

Similar content being viewed by others

References

C. Elangeswaran, K. Gurung, R. Koch, A. Cutolo, and B. Van Hooreweder, Fatigue Fract. Eng. Mater. Struct. 43, 2359 (2020).

X. Yan, C. Chen, R. Zhao, W. Ma, R. Bolot, J. Wang, Z. Ren, H. Liao, and M. Liu, Surf. Coat. Technol. 371, 355 (2019).

J. Mutua, S. Nakata, T. Onda, and Z. Chen, Mater. Des. 139, 486 (2018).

Y. Wei, G. Chen, M. Li, W. Li, Y. Zhou, J. Xu, and W. Zhou, J. Manuf. Process. 84, 750 (2022).

Z. Zhang, R. Wang, Y. Lv, W. Liu, and Y. Liu, Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 851, 143588 (2022).

R. Han, X. Li, H. Chen, Y. Peng, D. Yan, and K. Wang, J. Mater. Res. Technol. JMRT 24, 4517 (2023).

B. Almangour, D. Grzesiak, T. Borkar, and J. Yang, Mater. Des. 138, 119 (2018).

C. Jiang, J. Liu, Y. Wang, S. Luo, and B. Niu, Trans. Indian Inst. Met. 76, 1635 (2023).

J. Huebner, P. Rutkowski, A. Dębowska, and D. Kata, Mater. 13, 2932 (2020).

A. Malakizadi, D. Mallipeddi, S. Dadbakhsh, R. M’Saoubi, and P. Krajnik, Int. J. Mach. Tools Manuf 179, 103908 (2022).

S. Yin, C. Chen, X. Yan, X. Feng, R. Jenkins, P. O’Reilly, M. Liu, H. Li, and R. Lupoi, Addit. Manuf. 22, 592 (2018).

J.H. Yu, Q. Jin, K. Ha, and W. Lee, Appl. Sci.-Basel. 13, 6572 (2023).

K. Wang, H. Long, Y. Chen, M. Baniassadi, Y. Rao, and Y. Peng, Compos. Pt. A-Appl. Sci. Manuf. 147, 106460 (2021).

J. Kobylinski, L. Hitzler, R. Lawitzki, C. Krempaszky, A. Öchsner, and E. Werner, Isr. J. Chem. 60, 607 (2020).

C. Wei, Z. Zhao, H. Ye, Y. Yang, J. Tang, X. Shen, and G. Le, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 833, 142561 (2022).

M. Masoumi, I.F. de Barros, L.F.G. Herculano, H.L.F. Coelho, and H.F.G. de Abreu, Mater Charact 120, 203 (2016).

L.P.M. Dos Santos, M. Béreš, M.O. de Castro, P.W.C. Sarvezuk, L. Wu, L.F.G. Herculano, A. Paesano, C.C. Silva, M. Masoumi, and H.F.G. de Abreu, JOM 72, 3502 (2020).

C. Chen, Y. Xie, X. Yan, R. Huang, M. Kuang, W. Ma, R. Zhao, J. Wang, M. Liu, Z. Ren, and H. Liao, J. Alloys Compd. 785, 499 (2019).

M.J. Paul, Y. Muniandy, J.J. Kruzic, U. Ramamurty, and B. Gludovatz, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 844, 143167 (2022).

J. Yi, B. Niu, L. Pan, X. Zou, Y. Cao, X. Wang, J. Luo, and Y. Hu, Surf. Coat. Technol. 447, 128823 (2022).

J. Hu, H. Zhu, J. Zhang, M. Ouyang, C. Qiu, and J.A. Duan, J. Mater. Process. Technol. 296, 117213 (2021).

B. Yao, Z. Li, B. Teng, and J. Liu, Rapid Prototyp. J 29, 1240 (2023).

H. Majdi, J.A. Esfahani, and M. Mohebbi, Comput. Electron. Agric. 156, 574 (2019).

Z. Zhang, J. Yan, X. Lu, T. Zhang, and H. Wang, J. Mater. Res. Technol. JMRT. 24, 6923 (2023).

B.S. Mohammed, V.C. Khed, and M.F. Nuruddin, J. Clean. Prod. 171, 1605 (2018).

C.C. Nwaeju, F.O. Edoziuno, and E.E. Nnuka, Mater. Today: Proc. 56, 2371 (2022).

Y. Cao, S. Chen, H. Zhang, J. Feng, J. Sun, and W. Shi, Mater. Today Commun. 30, 103203 (2022).

K.M. Prasath, and R. Madesh, Mater. Today Proc. 46, 7119 (2021).

K. Umanath, K. Palanikumar, V. Sankaradass, and K. Uma, Mater. Today Proc. 46, 4019 (2021).

Y. Bai, C. Zhao, J. Yang, R. Hong, C. Weng, and H. Wang, J. Mater. Process. Technol. 288, 116906 (2021).

P. Nandwana, R. Kannan, D. N. Leonard, O. R. T. U. Oak Ridge National Lab. Ornl, JOM. 72, 4221(2020).

T. Allam, K.G. Pradeep, P. Köhnen, A. Marshal, J.H. Schleifenbaum, and C. Haase, Addit. Manuf. 36, 101561 (2020).

Y. Guo, H. Su, H. Gao, Z. Shen, Y. Liu, D. Zhao, P. Yang, Q. Hu, and Z. Zhang, J. Mater. Sci. Technol. 163, 81 (2023).

F.F. Conde, J.D. Escobar, J.P. Oliveira, A.L. Jardini, W.W. Bose-Filho, and J.A. Avila, Addit. Manuf. 29, 100804 (2019).

T. Tekin, G. Ischia, F. Naclerio, R. Ipek, and A. Molinari, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 872, 144921 (2023).

R. Casati, J. Lemke, A. Tuissi, and M. Vedani, Metals. 6, 218 (2016).

N. Kang, W. Ma, L. Heraud, M. El Mansori, F. Li, M. Liu, and H. Liao, Addit. Manuf. 22, 104 (2018).

H. Azizi, R. Ghiaasiaan, R. Prager, M.H. Ghoncheh, K.A. Samk, A. Lausic, W. Byleveld, and A.B. Phillion, Addit. Manuf. 27, 389 (2019).

O. Ertugrul, T. He, R.N. Shahid, and S. Scudino, J. Alloys Compd. 808, 151732 (2019).

Z. Yuan, H. Liu, Z. Ma, X. Ma, K. Wang, and X. Zhang, J. Alloys Compd. 928, 166985 (2022).

X. Yan, C. Huang, C. Chen, R. Bolot, L. Dembinski, R. Huang, W. Ma, H. Liao, and M. Liu, Surf. Coat. Technol. 371, 161 (2019).

J. Wang, L. Li, and W. Tao, Opt. Laser Technol. 82, 170 (2016).

J. Luo, J. Xu, and Z. Zhong, Rare Met. 32, 496 (2013).

S. Zhou, X. Dai, and H. Zheng, Opt. Laser Technol. 44, 190 (2012).

D. Gu, J. Ma, H. Chen, K. Lin, and L. Xi, Compos. Struct. 192, 387 (2018).

Acknowledgements

The project was funded by the Yunnan Fundamental Research Projects (202101AU070014), Project of the Science and Technology Major Project of Yunnan Province (202202AG050007), and Scientific Research Foundation of Yunnan Provincial Education Department (2022J0053).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shang, X., Fan, H., Yao, B. et al. Heat Treatment Optimization of Laser Powder Bed Fusion Formed WC/18Ni300 Maraging Steel Composites. JOM (2024). https://doi.org/10.1007/s11837-024-06609-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06609-z