Abstract

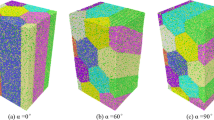

The effects of grain size and grain boundary misorientation on the deformation behavior of aluminum columnar nanograins under uniaxial tension in the direction parallel or perpendicular to grain boundaries are studied by molecular dynamics simulation. The results suggest that the average flow stress depends on grain size, grain boundary misorientation and directions of applied loading. The optimal grain size corresponding to the highest average flow strength is lower in columnar models than in the equiaxed random orientation models, and columnar models have higher strength. The formation of shear band occurs in the small grain size models (< 10 nm) with high-angle grain boundaries under columnar directional tension, and the deformation progresses from dislocation activities to shear bands formation. The deformed columnar grains were found to present different dislocation slip systems based on their different crystallographic orientation and load conditions. The high-angle grain boundary models subjected to tension in a direction perpendicular to the grain boundaries exhibit significant variations in plastic strain. These results also indicate that grain boundary activities such as migration and sliding increase in intensity with decreasing grain size.

Similar content being viewed by others

References

K. Kumar, H. Van Swygenhoven, and S. Suresh, Acta Mater. 51, 5743 (2003).

H. Van Swygenhoven and J.R. Weertman, Mater. Today 9, 24 (2006).

V. Yamakov, D. Wolf, S. Phillpot, A. Mukherjee, and H. Gleiter, Nat. Mater. 3, 43 (2004).

V. Turlo and T.J. Rupert, Acta Mater. 151, 100 (2018).

M. Dao, L. Lu, R. Asaro, J.T.M. De Hosson, and E. Ma, Acta Mater. 55, 4041 (2007).

Z. Liu, D. Zhao, P. Wang, M. Yan, C. Yang, Z. Chen, J. Lu, and Z. Lu, J. Mater. Sci. Technol. 100, 224 (2022).

J. Liu and A.C. To, Addit. Manuf. 16, 58 (2017).

Dd.C. Branco, L.S. de Vasconcelos, L. An, K. Zhao, and G.J. Cheng, J. Mech. Phys. Solids 151, 104391 (2021).

D. Ben, Y. Ma, H. Yang, L. Meng, X. Shao, H. Liu, S. Wang, Q. Duan, and Z. Zhang, Mater. Sci. Eng. A 798, 140109 (2020).

G. Singh, A.M. Waas, and V. Sundararaghavan, Comput. Mater. Sci. 200, 110807 (2021).

Q. Zeng, L. Wang, and W. Jiang, Crystals 11, 1388 (2021).

E. Hall, Proc. Phys. Soc. Sect. B 64, 747 (1951).

N. Petch, J. Iron Steel Inst. 174, 25 (1953).

H. Conrad and J. Narayan, Scripta Mater. 42, 1025 (2000).

Y. Tang, E.M. Bringa, and M.A. Meyers, Mater. Sci. Eng. A 580, 414 (2013).

L. Zhang, C. Lu, and K. Tieu, Comput. Mater. Sci. 118, 180 (2016).

A. Acharya and A. Roy, J. Mech. Phys. Solids 54, 1687 (2006).

X. Li, Y. Wei, W. Yang, and H. Gao, Proc. Natl. Acad. Sci. 106, 16108 (2009).

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, and H. Gleiter, Nat. Mater. 1, 45 (2002).

M.-J. Caturla, T. Nieh, and J. Stolken, Appl. Phys. Lett. 84, 598 (2004).

M.-J. Caturla and T. Nieh, In Nanomechanics of Materials and Structures, (Springer: 2006), pp 289–297.

S. Plimpton, J. Comput. Phys. 117, 1 (1995).

P. Hirel, Comput. Phys. Commun. 197, 212 (2015).

Y. Mishin, D. Farkas, M. Mehl, and D. Papaconstantopoulos, Phys. Rev. B 59, 3393 (1999).

A. Stukowski, Modell. Simul. Mater. Sci. Eng. 18, 015012 (2009).

A. Stukowski and K. Albe, Modell. Simul. Mater. Sci. Eng. 18, 085001 (2010).

L. Zhang, Y. Shibuta, X. Huang, C. Lu, and M. Liu, Comput. Mater. Sci. 156, 421 (2019).

V. Yamakov, D. Wolf, S. Phillpot, A. Mukherjee, and H. Gleiter, Philos. Mag. Lett. 83, 385 (2003).

A. Rida, E. Rouhaud, A. Makke, M. Micoulaut, and B. Mantisi, Phil. Mag. 97, 2387 (2017).

H. Dong, T. Xu, T. Ning, M. Liu, D. Wu, H. Ma, Z. Feng, B. Narayanaswamy, R. Su, and T. Wang, J. Mater. Res. Technol. 23, 77 (2023).

D. Gianola, S. Van Petegem, M. Legros, S. Brandstetter, H. Van Swygenhoven, and K. Hemker, Acta Mater. 54, 2253 (2006).

K.D. Molodov and D.A. Molodov, Acta Mater. 153, 336 (2018).

T. Rupert, D. Gianola, Y. Gan, and K. Hemker, Science 326, 1686 (2009).

Y.-B. Guo, T. Xu and M. Li, Appl. Phys. Lett., 102 (2013).

Y.-B. Guo, T. Xu, and M. Li, Phil. Mag. 92, 3064 (2012).

E. Castillo, Extreme value theory in engineering, (Elsevier, 2012).

M. Rahman, H. Zurob, and J. Hoyt, Acta Mater. 74, 39 (2014).

P. Cao, Nano Lett. 20, 1440 (2020).

P. Cao, Sci. Adv. 8, eabq7433 (2022).

Acknowledgements

This work was supported by NSF CAREER Award (CMMI- 2015598).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dong, S., Zhou, C. Plastic Deformation in Aluminum Columnar Nanograins. JOM (2023). https://doi.org/10.1007/s11837-023-06247-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-023-06247-x