Abstract

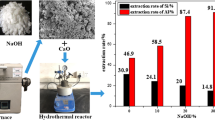

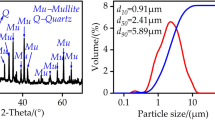

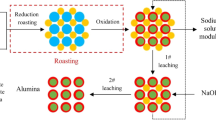

Efficient removal of silica is the key to alumina extraction from coal fly ash (CFA) by the Bayer process, due to the easy formation of sodium aluminosilicate hydrates during alkaline digestion. Considering the main mineral of well-crystallized mullite in CFA, mechanical activation was used in this work to improve the silica removal during reduction roasting–alkaline leaching. The phase transformations occurring in CFA during mechanical activation, reduction roasting, and alkaline leaching were systemically investigated through MAS-NMR, XRD, and SEM-EDS analyses. The results showed that the mean particle size (d(50)) decreased from 17.98 μm in CFA to 2.03 μm in activated CFA for 10 min with prolonging mechanical activation time, with the corresponding Al(IV) content decreasing from 73.82% to 67.85%. After pre-treatment with mechanical activation, the conversion of CFA into hercynite and silica solid solutions (i.e., quartz solid solution and cristobalite solid solution) was improved during reduction roasting with hematite, and the silica leaching ratio increased from ~ 70% to ~ 90% during the alkaline leaching. The obtained leaching residue with an alumina to silica mass ratio of > 10 was a decent raw material for the Bayer process to extract alumina. This study lays the foundation for comprehensive utilization of CFA.

Similar content being viewed by others

References

A.K. Tripathy, B. Behera, V. Aishvarya, A.R. Sheik, B. Dash, C.K. Sarangi, B.C. Tripathy, K. Sanjay, and I.N. Bhattacharya, Miner. Eng. 131, 140 https://doi.org/10.1016/j.mineng.2018.10.019 (2019).

Z. Yao, X. Ji, P.K. Sarker, J. Tang, L. Ge, M. Xia, and Y. Xi, Earth-Sci. Rev. 141, 105 https://doi.org/10.1016/j.earscirev.2014.11.016 (2015).

L.M. Delitsyn, A.S. Vlasov, T.I. Borodina, N.N. Ezhova, and S.V. Sudareva, Therm. Eng. 60, 231 https://doi.org/10.1134/S0040601513040034 (2013).

Q. Tian, B. Guo, S. Nakama, L. Zhang, Z. Hu, and K. Sasaki, Waste Manage. 86, 23 https://doi.org/10.1016/j.wasman.2019.01.027 (2019).

D. Valeev, P. Bobylev, N. Osokin, I. Zolotova, I. Rodionov, C. Salazar-Concha, and K. Verichev, J. Cleaner Prod. 363, 132360 https://doi.org/10.1016/j.jclepro.2022.132360 (2022).

J. Ding, S.H. Ma, S. Shen, Z. Xie, S. Zheng, and Y. Zhang, Waste Manage. 60, 375 https://doi.org/10.1016/j.wasman.2016.06.009 (2017).

P. Shao, H. Hou, W. Wang, and W. Wang, Ore Geol. Rev. 158, 105476 https://doi.org/10.1016/j.oregeorev.2023.105476 (2023).

Z. Yao, M. Xia, P.K. Sarker, and T. Chen, Fuel 120, 74 https://doi.org/10.1016/j.fuel.2013.12.003 (2014).

J. Xiao, F. Li, Q. Zhong, H. Bao, B. Wang, J. Huang, and Y. Zhang, Hydrometallurgy 155, 118 https://doi.org/10.1016/j.hydromet.2015.04.018 (2015).

A.B. ElDeeb, V.N. Brichkin, R.V. Kurtenkov, and I.S. Bormotov, Appl. Clay Sci. 172, 146 https://doi.org/10.1016/j.clay.2019.03.008 (2019).

W. Yu, Z. Rao, H. Yuan, P. Wei, J.E. Nyarko-Appiah, and W. Jiang, J. Cleaner Prod. 408, 137129 https://doi.org/10.1016/j.jclepro.2023.137129 (2023).

V.L. Rayzman, A.V. Aturin, I.Z. Pevzner, V.M. Sizyakov, L.P. Ni, and I.K. Filipovich, JOM 55, 47 https://doi.org/10.1007/s11837-003-0105-z (2003).

G. Qiu, T. Jiang, G. Li, X. Fan, and Z. Huang, Scand. J. Metall. 33, 121 https://doi.org/10.1111/j.1600-0692.2004.00677.x (2004).

C. Yang, J. Zhang, S. Li, H. Li, X. Hou, and G. Zhu, Waste Manage. 116, 190 https://doi.org/10.1016/j.wasman.2020.08.003 (2020).

M. Xie, F. Liu, H. Zhao, C. Ke, and Z. Xu, J. Mater. Res. Technol. 14, 2281 https://doi.org/10.1016/j.jmrt.2021.07.129 (2021).

A. Senyuta, A. Panov, A. Suss, and Y. Layner, Light Met. https://doi.org/10.1007/978-3-319-65136-1_36 (2013).

P. Smith, Hydrometallurgy 98, 162 https://doi.org/10.1016/j.hydromet.2009.04.015 (2009).

X. Li, H. Wang, Q. Zhou, T. Qi, G. Liu, Z. Peng, and Y. Wang, Trans. Nonferrous Met. Soc. China 29(2), 416 https://doi.org/10.1016/S1003-6326(19)64951-4 (2019).

H. Wang, X. Zhang, C. Liu, and L. Shen, J. Sustain. Metall. 7, 1686 https://doi.org/10.1007/s40831-021-00433-4 (2021).

P. Balaz, Int. J. Miner. Process. 72(1–4), 341 https://doi.org/10.1016/S0301-7516(03)00109-1 (2003).

M.K. Beyer, and H. Clausen-Schaumann, Chem. Rev. 105(8), 2921 https://doi.org/10.1021/cr030697h (2005).

Y. Guo, K. Yan, L. Cui, and F. Cheng, Powder Technol. 302, 33 https://doi.org/10.1016/j.powtec.2016.08.034 (2016).

X.B. Li, H.Y. Wang, Q.S. Zhou, T.G. Qi, G.H. Liu, Z.H. Peng, and Y.L. Wang, Trans. Nonferrous Met. Soc. China 29(1), 186 https://doi.org/10.1016/S1003-6326(18)64927-1 (2019).

B. Sulikowski, Microporous Mesoporous Mater. 206, 144 https://doi.org/10.1016/j.micromeso.2014.12.024 (2015).

Z. Zujovic, W.V.K. Wheelwright, P.A. Kilmartin, J.V. Hanna, and R.P. Cooney, Ceram. Int. 44, 2952 https://doi.org/10.1016/j.ceramint.2017.11.047 (2018).

Z. Ma, S. Zhang, H. Zhang, and F. Cheng, J. Cleaner Prod. 230, 302 https://doi.org/10.1016/j.jclepro.2019.05.113 (2019).

C. Guo, L. Zhao, J. Yang, K. Wang, and J. Zou, J. Cleaner Prod. 271, 122703 https://doi.org/10.1016/j.jclepro.2020.122703 (2020).

E.R. Segnit, and T. Gelb, Am. Mineral. 57, 1505 (1972).

D. Croker, M. Loan, and B.K. Hodnett, Cryst. Growth Des. 8, 4499 https://doi.org/10.1021/cg8004739 (2008).

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (52004194), the University Synergy Innovation Program of Anhui Province (GXXT-2022-083) and the Scientific Research Foundation for High-level Talents of Anhui University of Science and Technology (2022yjrc25).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Wang, J., Li, J. et al. Mechanical Activation of Coal Fly Ash for the Improvement of Alumina–Silica Separation During Reduction Roasting–Alkaline Leaching Process. JOM 76, 1456–1466 (2024). https://doi.org/10.1007/s11837-023-06229-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06229-z